The vacuum pump is from German BECKER to meet all kinds of requirements for different products.

In addition, it also has automatic lubricator pump to prolong the life of the machine.

|

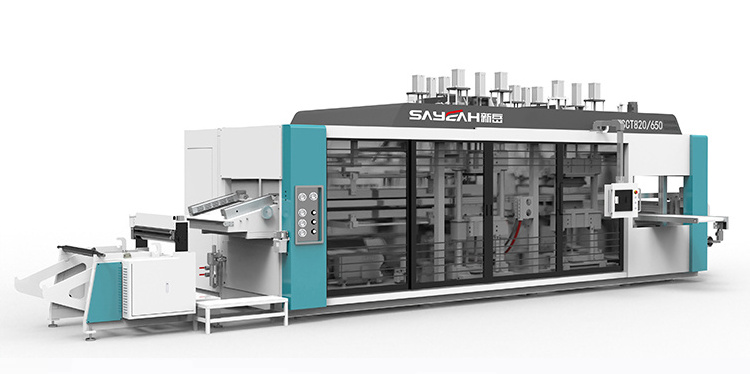

Model

|

FSCT-820/650-2

|

FSCT-820/650-3

|

FSCT-820/650-4

|

||

|

Quantity Of Stations

|

2

|

3

|

4

|

||

|

Sheet Material

|

PP, PS, PVC, PET, HIPS, PLA, OPS, EPS, C-PET, C-PLA, ABS

|

|

|

||

|

Application

|

Plastic lid, container, egg tray, fruit box, cake box, box, plate, flower pot, etc

|

|

|

||

|

Forming Clamping Force

|

750KN

|

|

|

||

|

Punching Clamping Force

|

750KN

|

|

|

||

|

Max. Forming Area

|

820 X 650 mm

|

|

|

||

|

Max. Pos/Neg Depth

|

150/150mm

|

|

|

||

|

Max. Plastic Sheet Width

|

860mm

|

|

|

||

|

Max. Plastic Sheet Dia.

|

1100mm,1T

|

|

|

||

|

Thickness Of Plastic Sheet

|

0.15-2mm

|

|

|

||

|

Max. No-Load Speed

|

65Cycles/min

|

|

|

||

|

Air Consumption

|

4.5m3/min,0.6-0.8Mpa

|

|

|

||

|

Overall Power

|

185 KW

|

200 KW

|

215 KW

|

||

|

Dimension

|

L10000 x W2900 x H3150mm

|

L11200 x W2900 x H3150mm

|

L12500 x W2900 x H3150mm

|

||

|

Weight

|

15T

|

20T

|

25T

|

||

|

Power Supply

|

380v/50Hz Three Phase Four Wires

|

|

|

||