- Product Details

- {{item.text}}

Quick Details

-

Cutting Material:

-

Rubber, Cork, Graphite, Felt, Asbestos, PTFE, etc.

-

Function:

-

Cutting, Marking, Punching

-

Cutting thickness:

-

1-100mm

-

Format Supported:

-

DXF, PLT

-

Working Area:

-

1600mmX2500mm

-

Cutting Accuracy:

-

≤0.1mm

-

Voltage:

-

220V 380V±10%,50HZ

-

Fixed Mode:

-

Vacuum Suction Table

-

Pump power:

-

7.5KW/9KW

Quick Details

-

Place of Origin:

-

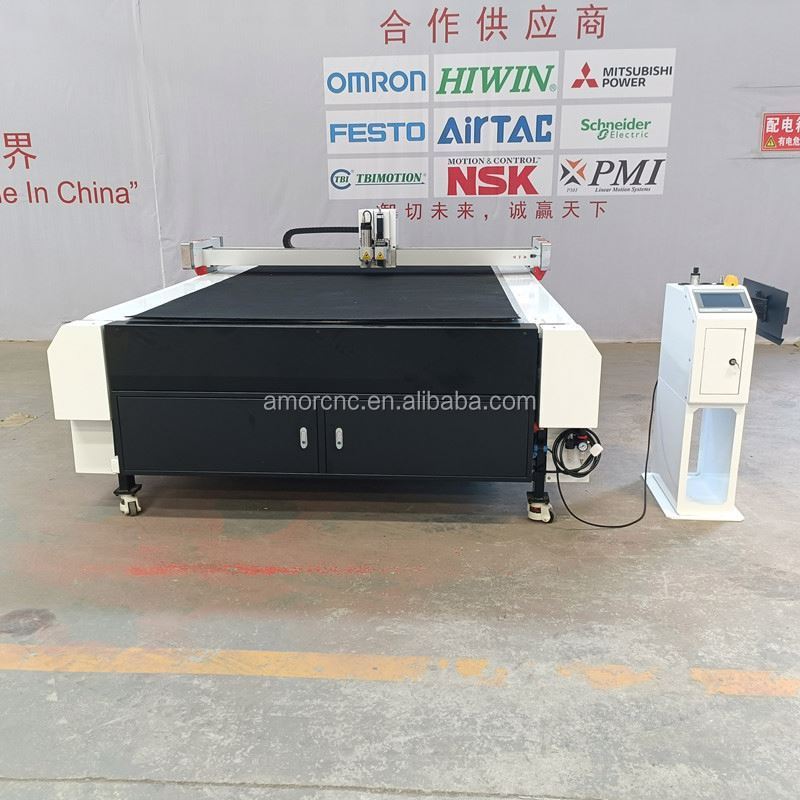

Shandong, China

-

Brand Name:

-

AMOR

-

Weight (KG):

-

1380

-

Cutting Material:

-

Rubber, Cork, Graphite, Felt, Asbestos, PTFE, etc.

-

Function:

-

Cutting, Marking, Punching

-

Cutting thickness:

-

1-100mm

-

Format Supported:

-

DXF, PLT

-

Working Area:

-

1600mmX2500mm

-

Cutting Accuracy:

-

≤0.1mm

-

Voltage:

-

220V 380V±10%,50HZ

-

Fixed Mode:

-

Vacuum Suction Table

-

Pump power:

-

7.5KW/9KW

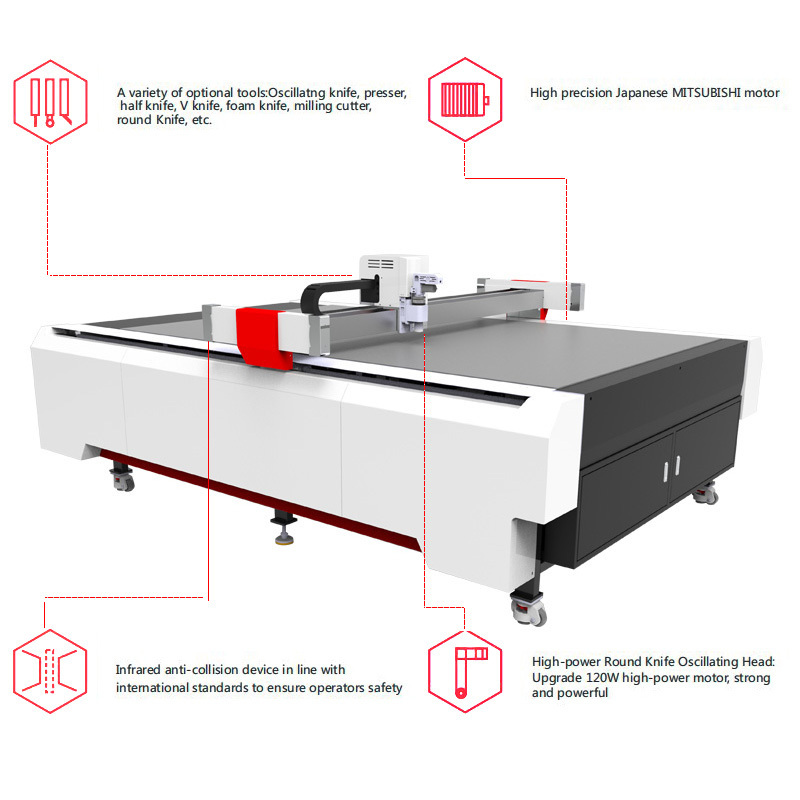

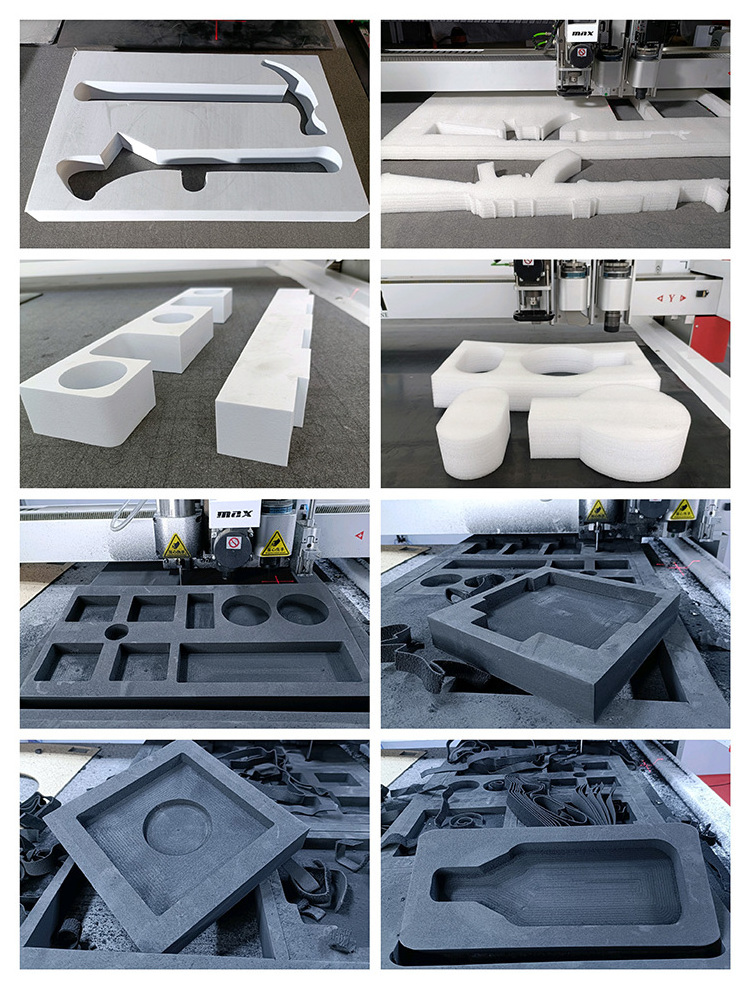

Products Description

The use of CNC oscillating knife cutting machines in the foam packaging industry underscores their importance in modern manufacturing. Their precision, efficiency, and versatility make them indispensable for creating high-quality, custom foam inserts that meet the dynamic needs of packaging for protection and transportation of goods. By leveraging such advanced technology, businesses can enhance their production capabilities, reduce costs, and improve overall product safety and presentation.

1. Material Compatibility

Oscillating knife cutters can efficiently cut a wide range of foams, including polyethylene (PE), polyurethane (PU), expanded polystyrene (EPS), EVA and cross-linked foams. Each of these materials is commonly used in packaging for their cushioning and shock absorption properties.

2. Precision and Complexity in Cutting

With the capability to cut complex shapes and intricate designs, oscillating knife machines are ideal for creating custom foam inserts that snugly fit around objects with irregular shapes or sensitive components.

3. Scalability and Customization

Oscillating knife machines can handle both small-scale bespoke productions and large-scale industrial runs, making them suitable for businesses of all sizes. Given the diverse needs of products requiring foam packaging, the ability to customize the cutting process is a significant advantage.

4. Reduced Need for Secondary Processing

Clean Cuts: The oscillating knife provides such clean cuts that there is often no need for additional finishing or treatment of the foam edges, which can be necessary with other cutting methods like die cutting or water jet cutting.

Product Paramenters

Professional Digital Cutter Polyethylene Insert For Epe Pe Eva Epp Shapes Cnc Foam Cutting Machine

|

Model

|

AMOR-1625MK

|

AMOR-2125MK

|

AMOR-2030MK

|

Customize

|

|||

|

Working Area

|

1600*2500mm

|

2100*2500mm

|

2000*3000mm

|

|

|||

|

Applicable Materials

|

Rubber, Cork, Felt, Foam, Asbestos, Non-asbestos, PTFE, Graphite, other non-metal gasket materials

|

|

|

|

|||

|

Drive Motor

|

Japan’s Mitsubishi Servo Motor and Drive

|

|

|

|

|||

|

Machine Advantage

|

1.The X axis is driven by double Japanese Mitsubishi servo motors;

2.The measurement adopts 7mm aviation aluminum alloy material, and

the mold is extruded;

3.All electrical accessories use the French Schneider brand.

|

|

|

|

|||

|

Cutting Thickness

|

0.1-45.0mm according to materials(Customizable maximum cutting thickness 110mm)

|

|

|

|

|||

|

Cutting Speed

|

1500mm/s

|

|

|

|

|||

|

Cutting tolerance

|

±0.1mm

|

|

|

|

|||

|

File Format

|

DXF, PLT

|

|

|

|

|||

|

Fixed Mode

|

Vacuum Partittion Adsorption

|

|

|

|

|||

|

Safety Devices

|

Use infrared sensing, safe and reliable

|

|

|

|

|||

|

Total Power

|

11KW (Vacuum pump power 9KW)

|

|

|

|

|||

|

Input Voltage

|

AC 220V 380V±10%,50HZ(Configurable transformer for customer location)

|

|

|

|

|||

|

Recommended Tools

|

High-power POT, 400W high-power EOT, high-speed milling cutter

|

|

|

|

|||

Applications

AMOR CNC oscillating digital knife cutter is widely used in the cutting and milling of EVA foam boards. It adopts advanced oscillating knife cutting technology with various cutting tools to meet different materails cutting. It can meet a variety of foam material cutting, such as EVA, EPE, sponge, EPS styrofoam and so on.

5 Advantages to Using AMOR CNC Oscillating Knife Cutter to Cut Foam:

1. More smart;

EVA foam automatic cutting machine does not need a mold, just process the processing data (PLT, DXF, AI format) into the system to cut, and can modify the size and shape of the processing graphics arbitrarily;

2. Save materials;

automatic nesting software can complete typesetting quickly and accurately without manual nesting. After actual testing, using an automatic cutting machine can save more than 10% of material compared to manual cutting;

3. Meet different foam cutting;

can cut foam of different width, thickness, and material. High cutting precision and flat cutting to meet the cutting requirements of complex graphics.

4. The processing site is more humanized;

AMOR EVA foam cutting machine adopts high-frequency oscillating knife cutting technology. Compared with laser cutting technology, the processing site has no soot, and the cutting speed is 3-4 times that of the laser. More environmentally friendly processing methods.

5. Achieve higher cutting efficiency;

AMOR EVA foam cutting machine adopts Japanese Mitsubishi servo motors with cutting speed of up to max 1500mm/s. Customers can also choose dual-oscillating tools to cut at the same time, which doubles the processing efficiency.

Recommended Tools

Selecting the right tools for a CNC oscillating knife cutting machine can significantly enhance the machine's capabilities in the foam packaging industry. By utilizing a combination of these tools, manufacturers can achieve versatile, efficient, and high-quality foam cutting and finishing, tailored to a wide range of packaging needs. This setup not only improves production efficiency but also enhances the quality and precision of the final products.

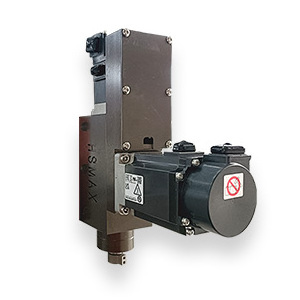

400W EOT Tool

Can be used to cut EVA foam with a hardness of 35-80, with a maximum cutting thickness of 120mm.

Making clean and precise cuts without compressing the material.

Pneumatic Tool

It can be used to cut EPE, EVA, EPS and other foam and sponge materials, with a maximum cutting thickness of 120mm.

Milling Tool

For rigid foams, a routing spindle can be employed to mill out material at greater depths and create detailed three-dimensional contours.

POT+Milling Tool

Can be used for cutting and engraving low-density, high-thickness foam materials. For example: EPE, EVA foam with hardness less than 50.

400W EOT + Milling Tool

It can be used for cutting and engraving high-density and high-thickness foam materials. For example: EVA foam with hardness 35-80.

400W EOT+Milling+POT

An all-in-one solution for cutting and engraving foam materials of different densities and thicknesses. For example: EPE, EVA foam.

Why Choose Us

The growing preference for AMOR CNC foam cutting machines among foam packaging manufacturers is rooted in these machines' ability to deliver high-quality, efficient, and versatile cutting solutions. These advantages not only enhance operational capabilities but also provide long-term benefits in terms of cost savings, making AMOR machines a strategic investment for businesses aiming to excel in the competitive foam packaging market.

Honeycomb Adsorption Platform

The thickness is 42.5mm, made of aviation aluminum alloy, with good flatness and a height error of 0.2mm.

Strong Power

The X-axis adopts the transmission mode of 2X400 Mitsubishi servo motor + precision reducer, which is powerful and high-precision.

Good Electrical Components

All electrical components are from international brands such as French Schneider, Japanese Omron, and American 3M.

Heavy Welded Bed

Reinforcing ribs are arranged inside the bed to increase the strength and tensile resistance of the bed, and effectively avoid deformation of the bed.

Aluminum Alloy Die Extrusion Beam

The wall thickness is 8mm and the width is 220mm. It has its own installation reference and has strong anti-deformation ability.

Vacuum Adsorption System

Supports multiple partition adsorption modes: according to graphics, cutting position and manual settings, etc. Hold the material firmly.

Hot Searches