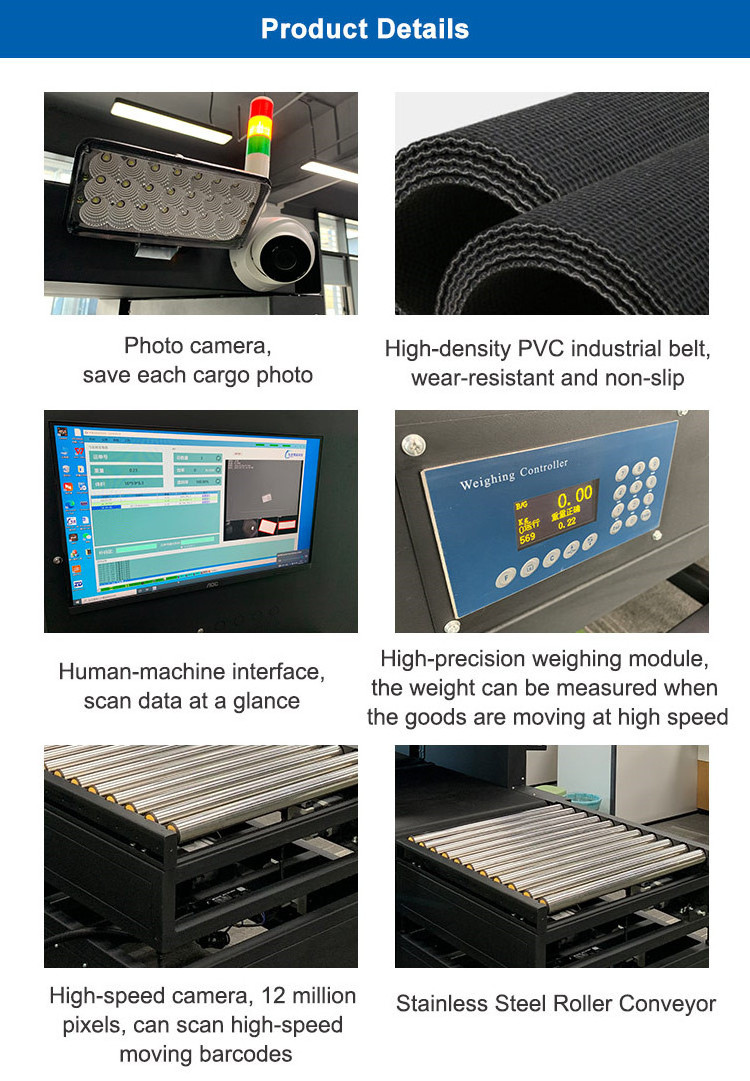

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Minwei

-

Voltage:

-

Local Power

-

Dimension(L*W*H):

-

Customized Size

-

Marketing Type:

-

Other

-

Weight (KG):

-

2000 kg

-

Style:

-

Custom

-

Color:

-

Customized Color

-

MOQ:

-

1 Set

-

Product Name:

-

Weighing and Measuring Machine

-

Feature:

-

Sturdy and Durable

-

Usage:

-

Material Conveying

-

Specification:

-

Customized

-

Bearing Capacity:

-

20-60KGS (Can be Customized)

-

After-sales Service Provided:

-

Provided

-

Keyword:

-

DWS System

Quick Details

-

Power:

-

Customized

-

Warranty:

-

1 Year

-

Width or Diameter:

-

600mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Minwei

-

Voltage:

-

Local Power

-

Dimension(L*W*H):

-

Customized Size

-

Marketing Type:

-

Other

-

Weight (KG):

-

2000 kg

-

Style:

-

Custom

-

Color:

-

Customized Color

-

MOQ:

-

1 Set

-

Product Name:

-

Weighing and Measuring Machine

-

Feature:

-

Sturdy and Durable

-

Usage:

-

Material Conveying

-

Specification:

-

Customized

-

Bearing Capacity:

-

20-60KGS (Can be Customized)

-

After-sales Service Provided:

-

Provided

-

Keyword:

-

DWS System

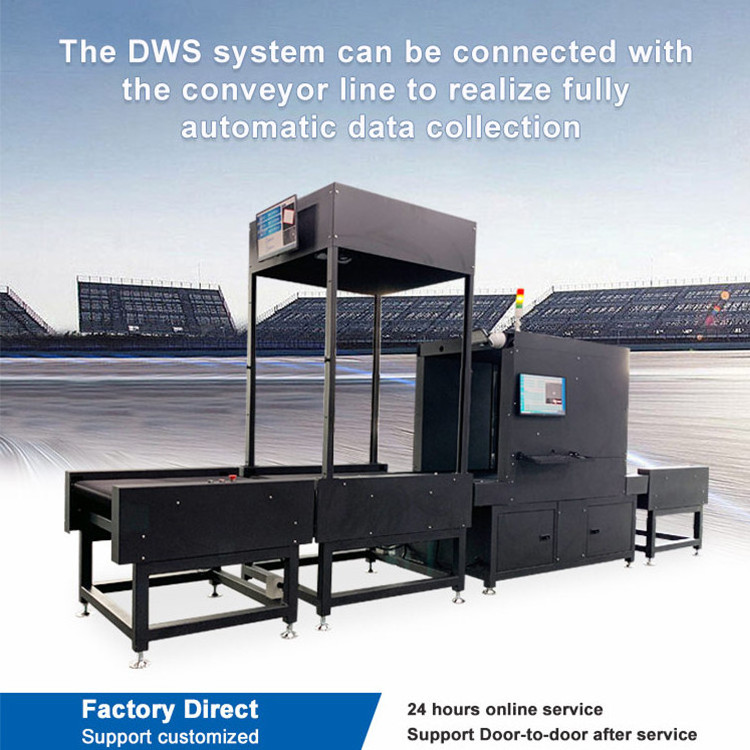

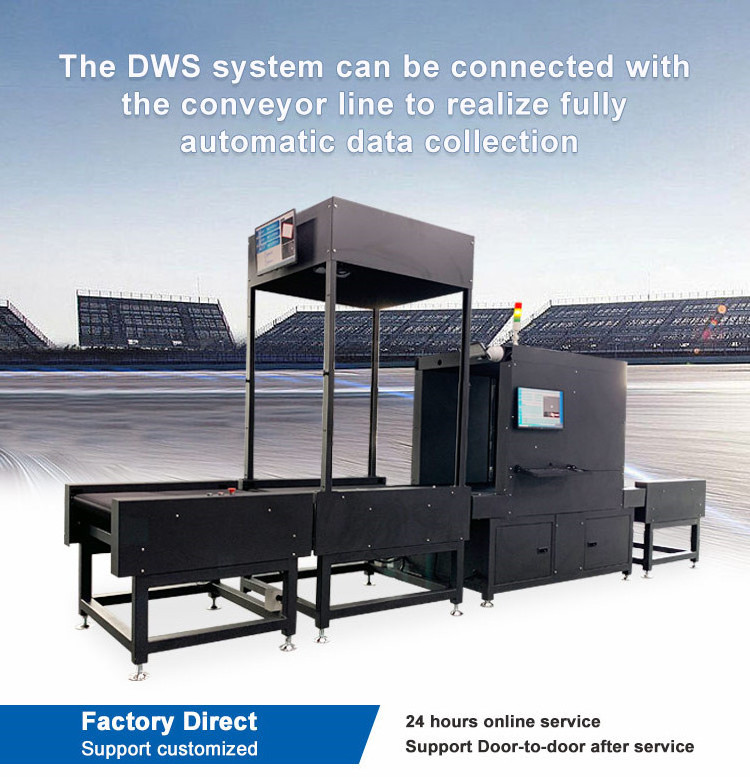

Mingwei DIMENSION WEIGHING AND SCANNING (DWS) SYSTEM

Incorrect parcel weight and dimension specification in the parcel handling industry are becoming a prevalent issue. Though verification can be done, it is slow and inefficient since it has to be manual.

Suppose your customers do not provide the correct weight and dimensional information. In that case, they are not paying the right amount and are you are losing revenue.

Dimensioning Weighing and Scanning (DWS) systems are a highly efficient way to capture parcel weight and dimensions for revenue protection and recovery. While capturing parcel specification, it also obtains information required for sortation purposes, optimal utilisation of space in transport vehicles or suitable temporary storage locations.

DWS systems are suitable for applications spanning from high-volume logistics and distribution companies to local shipping centres. The DWS systems bring value to all relevant operations involved in this industry.

The DWS systems are designed to be accurate, reliable, and efficient in capturing shipment and production data (dimensions, weight, barcodes). Accurate barcode data can be pushed in real-time for immediate information availability by seamlessly integrating with the DWS systems with existing warehousing and ERP systems.

USAGE:

1.Goods Profiling at Inbound for Storage Space Optimization and planning

2.Goods Profiling for Packing size recommendation during the packing stage

3.Calculation of Volumetric Weight for Freight reconciliation

4.Profile-based Quality check of actual vs expected

BENEFITS:

1.Increased Worker Productivity

Eliminates manual errors while measuring and logging

2.Opportunity to cap revenue leakages due to excess/ short billing

3.Increased Data trust from clients and partner

4.Avoid Storage Space related Chokes due to Cubic Volume visibility

5.Tighter Quality control on Order fulfilment

6.Dimension Weighing and Scanning (DWS) System

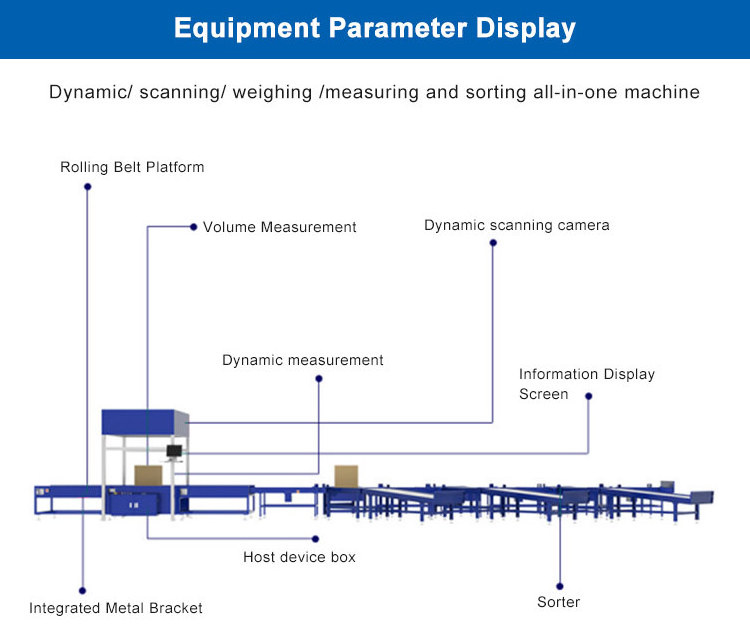

| Device name | High-speed scanning code weighing and volume measuring machine |

| Hardware |

HD code scanning camera(DH-MV-SL4800-S5B0-16)+handheld code scanning gun (auxiliary spare)can be customized for 5-side code scanning and 6-side code scanning) Intelligent high precision dynamic scale Dynamic high-precision volume measurement line(1mm grating infrared measurement and control technology) Industrial computer +LCD display+camera+light source+bracket Electronic Control(Hechuan/Mitsubishi/iemensPLC)Schneider Electronic Control Components Unpowered drum buffer section(1m) |

| SoftWare |

lmage forensics and photography software(color watermark+image archive +barcode map) DWS Supporting Software |

| Serve | Installation and commissioning + 1 year warranty+24 hours full service response |

| Working Efficiency | 1200-2400 pieces/hour |

| Technical Parameter |

Bar code recognition rate: ≥99.5% Weighing range: 0.1-50kg Weighing accuracy:±20g Dimensional measurement accuracy: average accuracy of flat wrapping +1mmmaximum error+5mm Cargo size(minimum): 100*10*10mm Cargo size(maximum):1000*800*800mm

|

| Abnormal Alarm |

Intercept abnormal situations such as damaged face sheetsunread face sheetsand intercepted piecesand handle exceptions manually |

| Working efficiency |

1200-2400 pieces/hour |

| Display Type |

LCD monitor |

| Weighing range |

0. 1-50kg |

| Weighing accuracy |

±20g |

| Cargo size (maximum) |

1000*800*800mm |