- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Size

-

Weight:

-

1500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

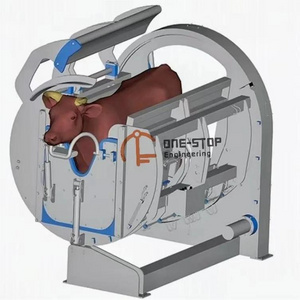

Suit for:

-

Cattle Slaughterhouse Plant

-

Product name:

-

Supply of slaughtering machinery slaughtering equipment food machinery

-

Advantage:

-

Customized Machine

-

Feature:

-

Customized Slaughter Line

-

Processing:

-

Complete Slaughter Line

-

Object:

-

Cattle Sheep

-

Local Service:

-

None

-

Usage:

-

Commercial

-

Type:

-

Professional

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

honyo

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

Size

-

Weight:

-

1500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Suit for:

-

Cattle Slaughterhouse Plant

-

Product name:

-

Supply of slaughtering machinery slaughtering equipment food machinery

-

Advantage:

-

Customized Machine

-

Feature:

-

Customized Slaughter Line

-

Processing:

-

Complete Slaughter Line

-

Object:

-

Cattle Sheep

-

Local Service:

-

None

-

Usage:

-

Commercial

-

Type:

-

Professional

Product Description

|

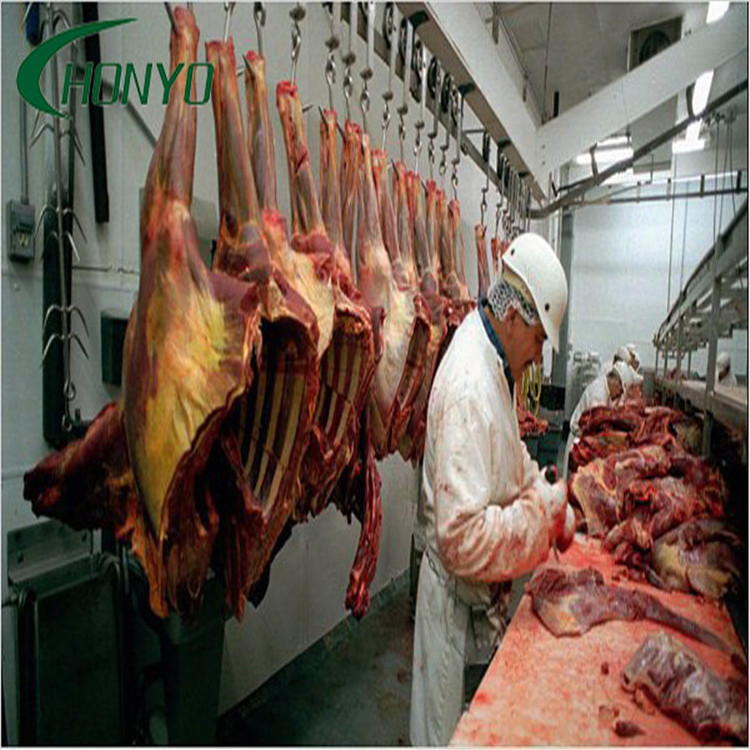

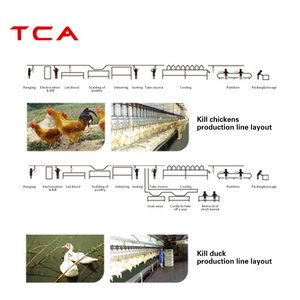

1. Brief Introduction of slaughtering line

Poultry slaughtering processingline refers to a kind of meat food machine which is used to slaughter cattle, sheep, chickens, ducks and other poultry. Slaughtering processing line is commonly applied to slaughtering poultry. The poultry to be slaughtered are put on the slaughtering transportation line, and the slaughtering transportation line is designed for transporting slaughtered chickens or ducks. In the process, work forces are reduced greatly. Besides, the set of equipment has a significant role in saving time and improving the production efficiency. And the equipment has an early iron capacity of 1000 ~ 12000 per hour. 2. Chickens Slaughter&Cutting Line: The min slaughering capacity is 500BPH. 1000-1200BPH is common used in slaughering house and customers require most. And if your slaughering capacity is huge , you could choose 2000BPH. |

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

Parameter

|

No.

|

Items

|

Unit

|

Qty

|

Remarks

|

||||

|

L.Slaughter/Scald/Defeather Section

|

|

|

|

|

||||

|

1

|

Hanging conveyor for slaughter

|

set

|

1

|

It consists of drive device,tensioning device,slewing gear,T rail, SUS T straight rail, bend rail and connections, SUS drive

chain, nylon hanger and SUS plastic trolley, SUS slaughter hook, conveying line length:48M, installating power:1.1KW |

||||

|

2

|

Waterbath stunning machine

|

set

|

1

|

SUS frame, insulation material groove

|

||||

|

3

|

Air-blowing scalding machine

|

set

|

1

|

Length:2.8M, scalding time:1minute;

It includes SUS air drived stirring system, 1 air blower, SUS poultry baffle, SUS shell and steam enclosed cover, SUS rail and corner wheel, water level auto control system,1 water temp auto control system, installating power:4KW |

||||

|

4

|

Vertical defeathering machine

|

set

|

1

|

Adjustable SUS frame, two parallel cabinets; total 6 rows with 8 plates each row, each plate has 12 rubber whips; 6 belt drive

devices, 6 high speed chinlon belts, feather baffle and SUS spray pipe are included; Installating power:9KW |

||||

|

5

|

Hook washing machine

|

set

|

1

|

SUS frame, 2 nylon brushes and motor drive, 2 SUS brush cabinet and spray pipes, Installating power:1.5KW

|

||||

|

6

|

Electric control cabinet (Model:DK-1)

|

set

|

1

|

Used to control the drive equipments in this section

|

||||

|

II. Evisceration Section

|

|

|

|

|

||||

|

1

|

Evisceration hanging conveyor

|

set

|

1

|

It consists of drive device,tensioning device,slewing gear,T rail, SUS T straight rail, bend rail and connections, SUS drive

chain, nylon hanger and SUS plastic trolley, SUS gut hook, conveying line length:35M, installating power:1.1KW |

||||

|

2

|

Evisceration reception chute

|

pc

|

4

|

SUS material

|

||||

|

3

|

Carcass washing device

|

set

|

1

|

Frame, shell and pipes are made from SUS

|

||||

|

4

|

Automatic poultry unhooking device

|

pc

|

1

|

Made from SUS

|

||||

|

5

|

Claw skin remover

|

set

|

1

|

It consists of SUS frame,SUS rotation disc and rubber stick ,SUS water spray pipe,installating power:2.2KW

|

||||

|

6

|

Electric control cabinet (model:DK-4)

|

set

|

1

|

Used to control the drive equipments in this section

|

||||

|

III. Carcass Pre-cooling Section

|

|

|

|

|

||||

|

1

|

Spiral pre-cooling Machince

|

set

|

1

|

Machine length:6M,Screw diameter:1.6M, including SUS chute, SUS tank and frame, SUS screw propulsion device, auto poultry output

system, air-blast system and air blower, motor reducer; Cooling media: cold water or brash ice(not include cold water chilling unit and slice ice machine) |

||||

|

2

|

Carcass reception chute

|

pc

|

1

|

Made from SUS

|

||||

|

3

|

Electric control cabinet (model:DK-4)

|

set

|

1

|

Used to control the drive equipments in this section

|

||||

|

IV. Subdividing cutting and Packaging Section

|

|

|

|

|

||||

|

1

|

Hanging conveyor for subdividing cutting

|

set

|

1

|

It consists of drive device,tensioning device,slewing gear,T rail, SUS T straight rail, bend rail and connections, SUS drive

chain, nylon hanger and SUS plastic trolley, SUS split hook, conveying line length:33M, installating power:1.1KW |

||||

|

2

|

Packaging worktable

|

set

|

8

|

SUS frame and adjustable legs, and SUS worktable

|

||||

|

3

|

Electric control cabinet (model:DK-4)

|

set

|

1

|

Used to control the drive equipments in this section

|

||||

FAQ

|

1.Are you a manufacturer or a trading company?

We are a manufacturer company, we have more than 200 wokers to produce the products. 2.Where is your company loaced in?Can I have a visit? Our factory is located in Shandong province and you are welcomed to our company! 3.How Can I contact you quickly? Any questions call or send information at any time. |

Hot Searches