Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

WEIER

-

Voltage:

-

380V,50HZ,3phase

-

Dimension(L*W*H):

-

4.6X3X4m

-

Power (kW):

-

240

-

Weight:

-

4.5 KG

-

Name:

-

PVC wood WPC co-extrusion decking board machine

-

Raw material:

-

PVC+WOOD+additives

-

Motor:

-

SIEMENS Brand

-

Inverter:

-

ABB Inverter

-

mould:

-

JC TIMES

-

Automatic Grade:

-

automatic

-

Marketing Type:

-

Hot Product 2020

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

80/173

-

Screw diameter (mm):

-

80 mm

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

WEIER

-

Voltage:

-

380V,50HZ,3phase

-

Dimension(L*W*H):

-

4.6X3X4m

-

Power (kW):

-

240

-

Weight:

-

4.5 KG

-

Name:

-

PVC wood WPC co-extrusion decking board machine

-

Raw material:

-

PVC+WOOD+additives

-

Motor:

-

SIEMENS Brand

-

Inverter:

-

ABB Inverter

-

mould:

-

JC TIMES

-

Automatic Grade:

-

automatic

-

Marketing Type:

-

Hot Product 2020

Description

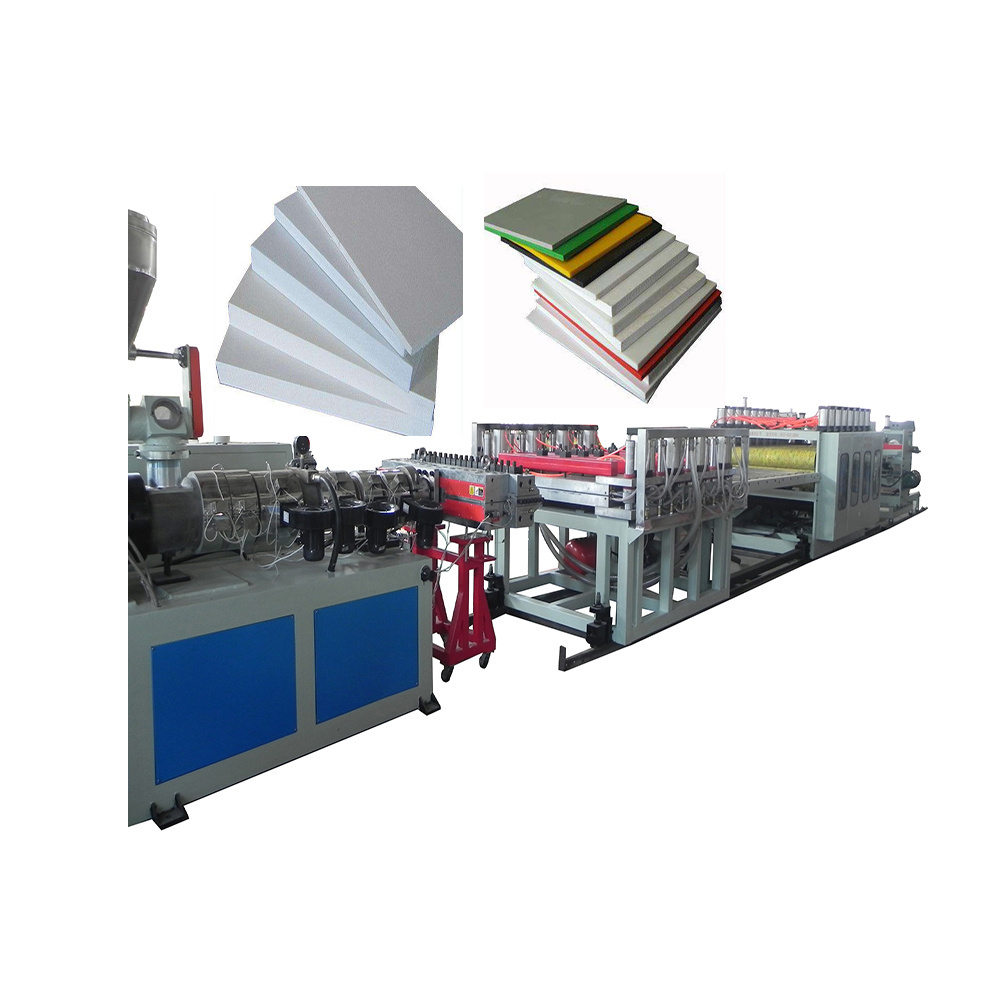

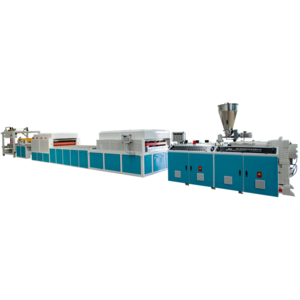

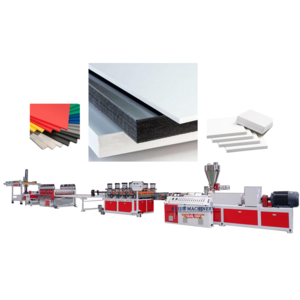

weier series wood-plastic board production line maily use PVC+wood powder,this product is mailly used for extruding construction template,furniture board,floor board and other decking board

Equipment list

1.1 conical twin-screw extruder

1.2 Extrusion mold

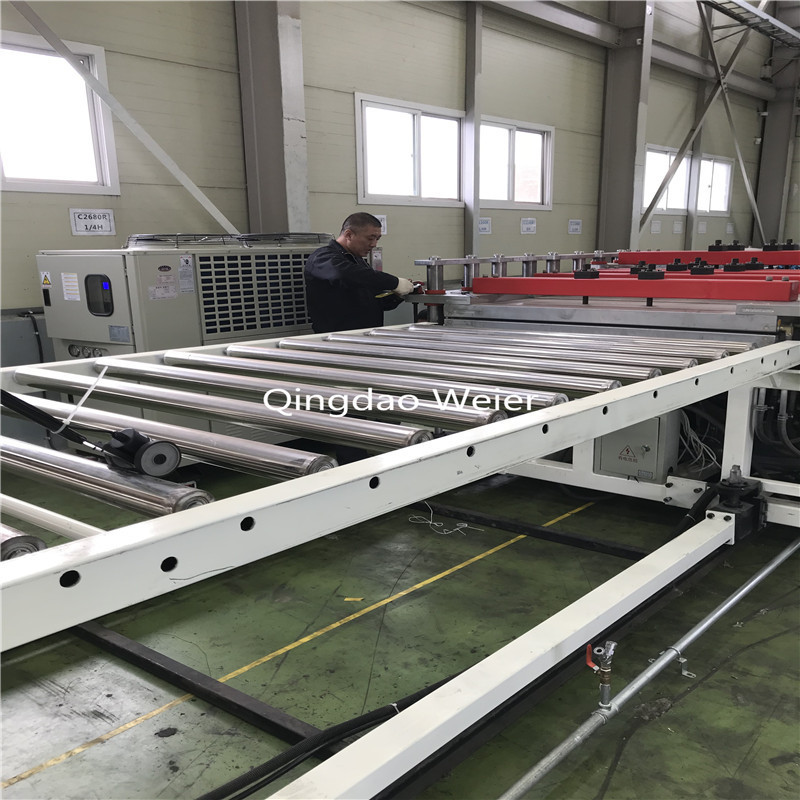

1.3 Hydraulic pressure calibration machine

1.4 Cooling conveyor Bridge

1.5 Edge cutting unit

1.6 Rollers Haul-off

1.7 Transverse cutter

1.8 Stacking table

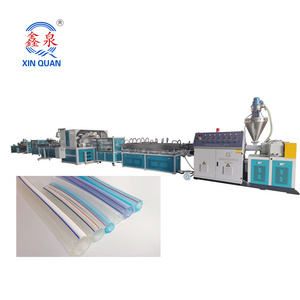

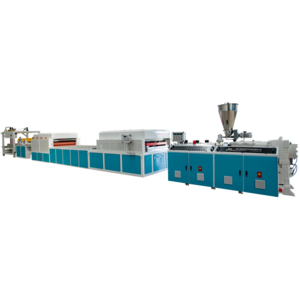

Related products

1.The machine body is covered by waterproof film firstly, and then fixed on exported wooden pallets with bolts and wires.

3.The auxiliary equipments are packaged in wooden box as well.

4.All wooden material is fumigation certificated and safe for exporting to all over the world.

Pre-sale

We provide presales service in various forms, for example, making investment budget, manufacturing planning, etc. so that customers make a reasonable plan with less cost.

Investment budgeting---We provide services of product profit analysis, recommendation of machine and auxiliary equipment and relevant budgeting, human resources allocation and budgeting.

Plant Planning---We provide the mounting dimension of the equipment base, design of equipment layout, workshop ventilation, water transmission etc.

On-sale

Detailed design of workshop lay-out

Technological information of provided products

Schedule about design, manufacture and installation

Working & Producing process

Training courses for the technician team so that the installation is safe and standard

After-sale

For customers buying our products, we provide them training so that they can use and maintain the machine independently.

We will offer to customers technical support in time. If needed, we will offer on-line guidance and assistance.

We can provide free technical guidance if customers need new equipment, add or rebuild equipment.

We will prioritize the product upgrading of previous customers.

Contact lisa liang

Cellphone: 0086 158 0652 8909

Wechat: 0086 158 0652 8909

Skype: 0086 158 0652 8909

Whatsapp: 0086 158 0652 8909

Email: caiyurui(a)weiersljx.com