- Product Details

- {{item.text}}

Quick Details

-

Power:

-

30kW

-

Weight:

-

2000 KG

-

Dimension(L*W*H):

-

16x0.85x1.8m

-

Screw design:

-

double screw

-

Usage:

-

breakfast cereals making

-

Function:

-

Multifunctional

-

Raw material:

-

Corn flour, rice flour, flour, cereal flour

-

Type:

-

Fully Automatic

-

After Warranty Service:

-

Online support

-

Application:

-

Food Processing Machine

-

Keywords:

-

breakfast cereals Making Machine

-

Feature:

-

High Efficiency Easy Operation

-

Name:

-

Automatic corn puffs making machine for factory

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DELON

-

Voltage:

-

380v

-

Power:

-

30kW

-

Weight:

-

2000 KG

-

Dimension(L*W*H):

-

16x0.85x1.8m

-

Screw design:

-

double screw

-

Usage:

-

breakfast cereals making

-

Function:

-

Multifunctional

-

Raw material:

-

Corn flour, rice flour, flour, cereal flour

-

Type:

-

Fully Automatic

-

After Warranty Service:

-

Online support

-

Application:

-

Food Processing Machine

-

Keywords:

-

breakfast cereals Making Machine

-

Feature:

-

High Efficiency Easy Operation

-

Name:

-

Automatic corn puffs making machine for factory

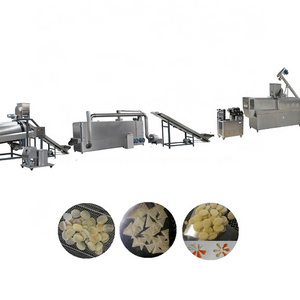

Hot Sale Puffed food extruder inflating corn snack making machine

Automatic corn puffs making machine for factory is full automatic processing line based on extrusion technology.

Main machine is twin screw extruder.

Twin screw extruder adopt

Corn flour, rice flour, flour, cereal flour

etc. as ingredients to make puffed snack. Through frication of screw and barrel, the grains are cooked in the extruder. Forming is at the die face cutter. The product shape is determined by a combination of the die aperture, including ball, tube, stick, ring, fruit loop, star, wheel and flower etc.

Layout : Automatic corn puffs making machine for factory

Device may contain : Automatic corn puffs making machine for factory

1> Mixer :Used for raw meterial mixing.

2>Screw hoister :Transfering the raw material to the feeder of twin screw extruder.

3>Twin screw extruder :Used for cooking and shaping.

4>Core filler : Used for injecting the core material at the instant when the extruder produces a hollow tube

5>Multi -function shaper : Shaping and cutting

6>Hoister:Transfering the product to the next step.

7>Dryer:Used for drying.

8>Flavoring machine:Used for flavoring.

9>Package machine:Used for packing.

Sample picture: Automatic corn puffs making machine for factory

Main features: Automatic corn puffs making machine for factory

1.The main extruder adopts frequency speed controlling with high automation and stable per-formation.

2.The screws are made of the alloy steel and special craft,durable usage,high pressure,the screw life is longer.Adopting the building block structure and combining willingly according to the different demand.

3.The forced lubrication system,so that it can guarantee the equipment transmission life is longer.

4.Auto-temperature control system, make the temperature controlling more direct viewing and the parameter more precise.

5.Self-cleaning ,when stopping ,it can be cleaned without disassembling.

6.According to different screw design rate to full different technology request.

7.This equipment has the wide material,multi-shape products and flexible collocations.We can produce the different products according to the different models (pellet, flower,star , ring , moon , ball , stick,animal or grain )and collocations.

"Low cost, high profits" is the suitable generalization of Snack food business line, especially for puff snack food production can produce many kinds of snacks/puffed snacks such as crispy rice flakes,core-filling snacks,cereal porridge,nutritional powder(instant porridge) etc.

|

Technical parameter for Automatic corn puffs making machine for factory

|

|

|

|

|||

|

Model

|

DL65

|

DL70

|

DL70

|

|||

|

Input Voltage

|

380V/50HZ or Customized

|

|

|

|||

|

Installed Power(kW)

|

35

|

42

|

46

|

|||

|

Power Consumption(kW)

|

22

|

30

|

|

|||

|

Production capacity(kg/h)

|

120~150

|

150~200

|

|

|||

|

Length(mm)

|

16

|

18

|

|

|||

Pre-Sales Service

a). Free consultation service

b). Free project planning and design services;

c). Free sample testing support.

After-Sales Service

a). Field installation, commissioning and training;

b). Free new production techniques and formulas;

c). Provide 1 year complete warrantee and life-time maintance service.

Jinan Delon Machinery & Equipment Co., Ltd. is a high and new technology enterprise integrating technology, manufacture and trade. We have devoted ourselves to developing, manufacturing and trading double/single screw extruders, snack production lines, breakfast cereal/corn flake production lines, soya meat production lines, pasta/macaroni production lines, pet food production lines, etc. for more than 10 years.

Q:Are you manufacturer?

A: Yes,

we are

manufacturer,

welcome to visit our factory and check the machines.

Q: Can you design new mold for us if we have good idea?

A: Yes,we can design new mold for you according to your original market needs.

Q:Can you help us to design the whole line if we provide the layout of our factory?

A:Yes,we can provide you machine layout at your factory after get your factory details.

Q: What information should I provide, if I want a quotation?

A:┅

The kind of machine you choose, or offer me the kinds of food you will produce.

--- Your production capacity requirement.

---Provide us your production details, then we give professional suggestion to you.

Q: Why choose us?

A: --- Professional technology, we have been engaged in manufacturing food processing machine for many years, accumul ating rich experience and enjoying high reputation.

┅Fast delivery and good service.

┅All the machines are strictly inspected before making shipment.

---Alibaba assessed supplier.

---Provide basic formula.