- Product Details

- {{item.text}}

Quick Details

-

Output paper style:

-

tissue paper

-

Paper weight:

-

15-30g/m2

-

The width of final jumbo paper roll:

-

2900mm

-

Width of cylinder mould:

-

3350mm

-

Capacity:

-

10Tons/day

-

Work speed:

-

180-220m/min

-

Machine specifications:

-

Upside down slurry form

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Free spare parts, Video technical support, Field maintenance and repair service, Online support

Quick Details

-

Production Capacity:

-

95%

-

Place of Origin:

-

China

-

Power:

-

45kw

-

Output paper style:

-

tissue paper

-

Paper weight:

-

15-30g/m2

-

The width of final jumbo paper roll:

-

2900mm

-

Width of cylinder mould:

-

3350mm

-

Capacity:

-

10Tons/day

-

Work speed:

-

180-220m/min

-

Machine specifications:

-

Upside down slurry form

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Free spare parts, Video technical support, Field maintenance and repair service, Online support

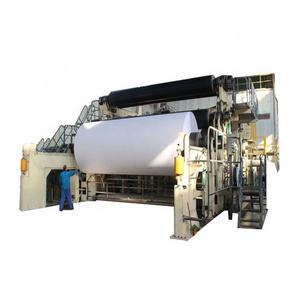

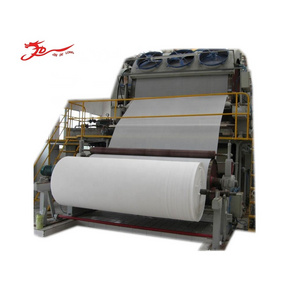

10 tons/day Recycled Waste Paper Jumbo Tissue Paper

Roll Production Line

Introduction:

Paper machine product technological process:

Cloth wash section + Cylinder mould forming section + Drying section Φ3000 Dryer + Scraper wrinkling + Pneumatic reel section + Transmission section

The main characteristics of every section

1.Washing press section

2.Forming section

3.Dry section

4.Reel section

5.Transmission

Specification:

1. Raw material: waste paper, virgin pulp

2. Output paper style: tissue paper

3. Paper weight: 15-30g/m2

4. The width of final jumbo paper roll: 2900mm

5. Width of cylinder mould: 3350mm

6. Capacity : 10Tons/day

7. Work speed: 180-220m/min

8. Machine specifications: Upside down slurry form

Picture of machine:

Quality is our forte and we have clients spreading all over the world. We are committed to a well-defined and self-framed quality policy. The policy revolves around through and repeated checking of the products. We are the regular exporters of our products throughout Asia, Africa and several European countries. Our after-sales service terms and conditions as follows.

- Tissue Paper Prodution Line are tested and have trial production in our factory before leaving our factory and they are shipped out only after the customers are satisfied with them

- When the machines are tested, our technicians will train the customers’ technicians in theory and practice till they grasp the skills.

- During this period of one year warranty , if the machines were damaged by non-artificial reasons, we are responsible for repairing or changing parts.

- During this period of warranty, if there is something wrong with the machine, we are responsible to provide project for solving this problem at the soonest, and help customers to restore production as soon as possible.

- After the warranty, we charge only cost price for maintaining the machines within three years.

- Other after-sale terms can be agreed by buyer and seller in addition.