- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

1500mm*30000mm/6000mm*2000mm

-

Cutting Thickness:

-

0.2~40mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

China

-

Brand Name:

-

blue elephant

-

Weight (KG):

-

15000 KG

-

Product name:

-

Fiber Laser Metal Cutting Machine

-

Keyword:

-

Fiber Laser Cuting Machine

-

Function:

-

Cutting Metal Materials

-

After-sales Service Provided:

-

Online Support

-

Cutting materials:

-

Stainless Steel Carbon Steel

-

Model:

-

Processing Metal

-

Working area:

-

1500mmX3000mm / 2000mmX4000mm / 2000mmmX6000mm

-

Fiber Laser Source:

-

1000W - 20000W Optional

-

After Warranty Service:

-

Support Online Support

-

Color:

-

Blue-white

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

140meter/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

1500mm*30000mm/6000mm*2000mm

-

Cutting Thickness:

-

0.2~40mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

China

-

Brand Name:

-

blue elephant

-

Weight (KG):

-

15000 KG

-

Product name:

-

Fiber Laser Metal Cutting Machine

-

Keyword:

-

Fiber Laser Cuting Machine

-

Function:

-

Cutting Metal Materials

-

After-sales Service Provided:

-

Online Support

-

Cutting materials:

-

Stainless Steel Carbon Steel

-

Model:

-

Processing Metal

-

Working area:

-

1500mmX3000mm / 2000mmX4000mm / 2000mmmX6000mm

-

Fiber Laser Source:

-

1000W - 20000W Optional

-

After Warranty Service:

-

Support Online Support

-

Color:

-

Blue-white

Products Description

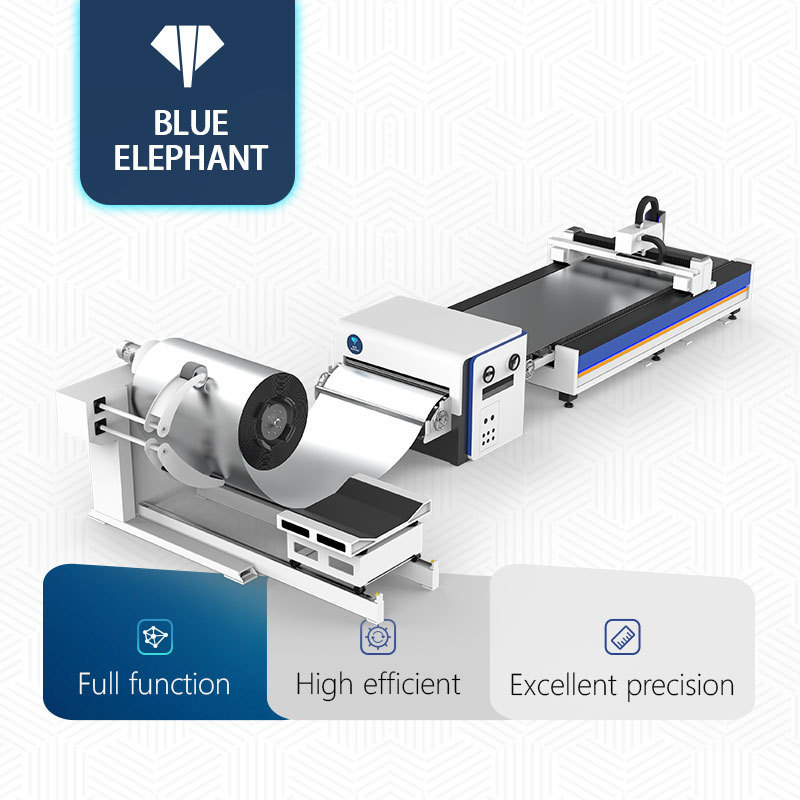

Top Ranked Automatic Coil Fed Laser Sheet Cutting Machine for Fiber Laser Metal Cutting Automatic Steel Cutting Router for Sale

The coil fed laser cutting machine is specially designed for automatic cutting of thin metal sheets. Especially thin stainless steel sheets. It realizes the loading, uncoiling, leveling and cutting processes automatically, which saves labor and improves working efficiency.

1. Improved loading efficiency.

The coil material weight reaches up to 20T, breaking through the limit of ordinary 3T loading. It is 6 times efficiency of ordinary loading equipment.

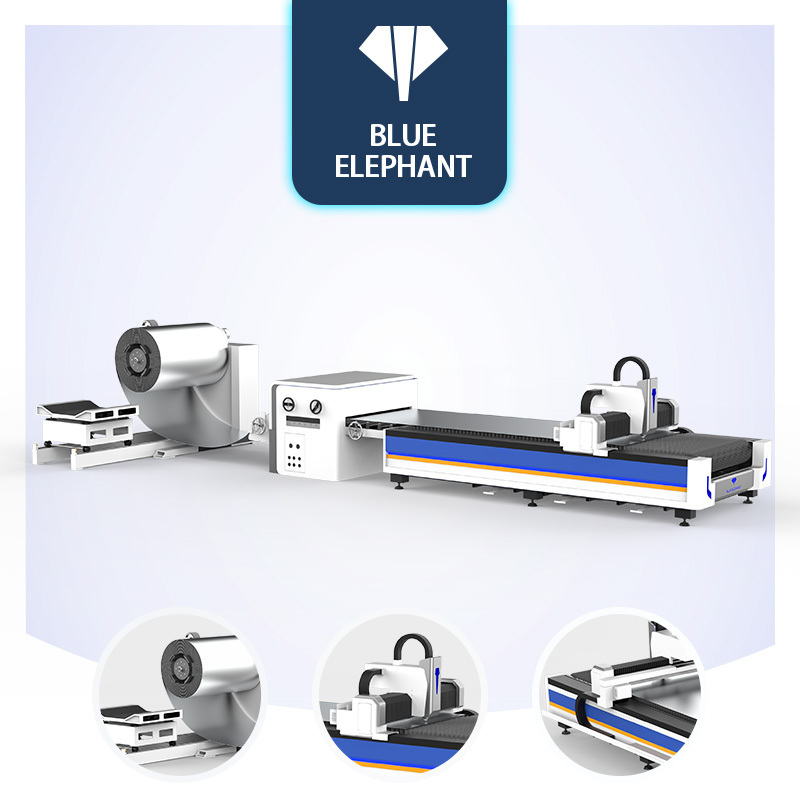

2. Stress relief.

After uncoiling the coil, the leveling machine will level the metal sheet and, at the same time, eliminate the stress of the sheet in the leveling process. This makes the sheet material more flat and suitable for cutting.

3. Ultra-precision transmission structure.

The machine adopts an ultra-precision transmission system, making the sheet material transmission accuracy within ±0.5mm and guaranteeing higher precision.

4. Automatic production line design.

This machine completes the whole cutting process automatically from feeding, uncoiling, leveling, cutting to discharging. The whole automated process saves labor, realizes the zero waste of coil material, and improves the utilization efficiency of sheet metal.

5. Unlimited material length.

This coil fed laser production line breaks through the limit of the previous laser cutting machine in the cutting length limit, and in some special areas, has a subversive significance.

Product Details

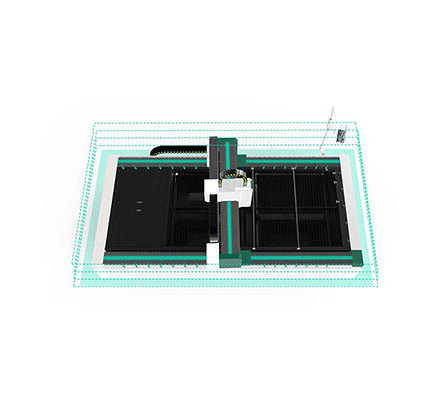

Automatic lubrication system

Whole body layout, automatic lubrication of guide rails and racks.

Automatic focusing laser head

Laser head follow-up function Follow the change of the height of the board, don't worry about the unevenness of the board affecting the cutting effect.

Max Laser Source

Raycus/Max/IPG, multiple choice different brands, different laser power are available. The higher power, the thicker cutting thickness.

Servo Motor

By adding and improving vibration suppression function, it can improve the following performance and shorten the setting time.

The aviation aluminum beam

The fiber laser cutting machine beam is processed by T6 heat treatment process to make the beam obtain the highest strength.

Thick-walled carbon steel plate welding bed

Adopting high-quality carbon plate steel welding bed, it is more stable and durable than normal tube welding bed. The

high-strength machine tool adopts 600 ℃ stress relief annealing treatment, which has strong structural rigidity, small deformation, and low vibration to ensure cutting accuracy.

high-strength machine tool adopts 600 ℃ stress relief annealing treatment, which has strong structural rigidity, small deformation, and low vibration to ensure cutting accuracy.

Product Paramenters

|

Model

|

ELECNC-1530FC

|

ELECNC-1540FC

|

ELECNC-2040FC

|

||

|

Total machine weight

|

6.2t

|

6.7t

|

6.9t

|

||

|

Working area (mm)

|

1515*3030

|

1515*4040

|

2020*6060

|

||

|

Max. acceleration

|

1.5G

|

1.5G

|

1.5G

|

||

|

Worktable

|

Rolling blade

|

|

|

||

|

Positioning accuracy

|

±0.05mm

|

|

|

||

|

Repositioning accuracy

|

±0.03mm

|

|

|

||

|

Laser power

|

1kW - 2kW

|

|

|

||

|

Coil sheet thickness

|

0.5-3mm

|

|

|

||

|

Machine bed

|

Plate welded bed

|

|

|

||

|

Laser

|

Multiple options

|

|

|

||

|

Focusing method

|

Auto/manual

|

|

|

||

|

X/Y-axis max. linkage speed

|

140m/min

|

|

|

||

|

Leveling speed

|

≤20m/min

|

|

|

||

|

Coil weight

|

≤15t

|

|

|

||

Sample & Application

Hot Searches