- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V, 3P

-

Power:

-

1KW

-

Weight:

-

2100 KG

-

Dimension(L*W*H):

-

1100*1200*1500MM

-

Product Name:

-

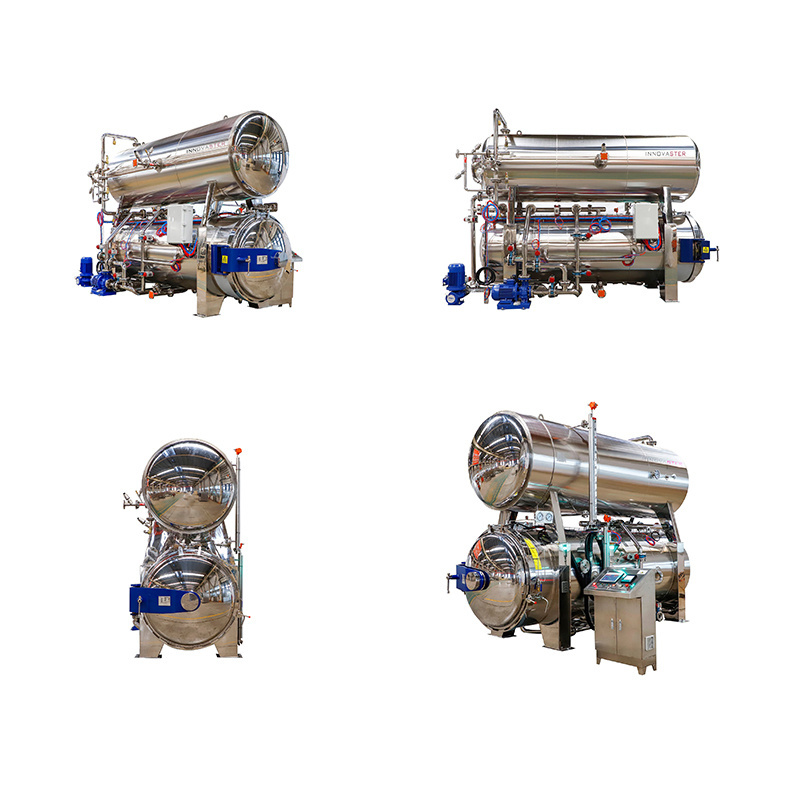

High Temperature High Pressure Food Processing Retort Machine

-

Raw Material:

-

304 Stainless Steel

-

Application:

-

High Temperature Sterilization

-

HS CODE:

-

841989

-

Operation:

-

Automatic Batch Retort

-

Property:

-

Physical Sterilization

-

Auxiliary:

-

Boiler, Cooling Tower, Air Compressor

-

Structure:

-

Cylindrical Pressure Vessel

-

Type:

-

High Temperature Sterilization

-

Medium:

-

Steam, Water, Air

Quick Details

-

Marketing Type:

-

New Product 2021

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Innovaster

-

Voltage:

-

380V, 3P

-

Power:

-

1KW

-

Weight:

-

2100 KG

-

Dimension(L*W*H):

-

1100*1200*1500MM

-

Product Name:

-

High Temperature High Pressure Food Processing Retort Machine

-

Raw Material:

-

304 Stainless Steel

-

Application:

-

High Temperature Sterilization

-

HS CODE:

-

841989

-

Operation:

-

Automatic Batch Retort

-

Property:

-

Physical Sterilization

-

Auxiliary:

-

Boiler, Cooling Tower, Air Compressor

-

Structure:

-

Cylindrical Pressure Vessel

-

Type:

-

High Temperature Sterilization

-

Medium:

-

Steam, Water, Air

Horizontal juice glass bottle mushroom jar pet canning sterilization retort

Working Process

Superheated water contained in the storage vessel allows for a short come-up time.

Hot water envelops the containers thus even temperature penetration into the products from all sides.

Optimized water circulation system guarantees homogenous temperature distribution.

Less stress on the containers achieved by the buoyancy effect from immersing the load in water, such as semi-rigid trays, pouches etc.

Rotary agitation function is available, perfect for products of high viscosity, such as condensed milk, flavored milk in plastic bottles, canned corn which need End-over-end rotation for forced convection or prevent burning on the container walls during heating.

In a Water Immersion process these steps are:

1.Prepare Tank (Water Heating)

2.Come Up Fill (A Sterilization Step)

3.Come Up (A Sterilization Step)

4.Cook (A Sterilization Step)

5.Pressure Cool Fill

6.Pressure Cool

7.Atmospheric Cool

8.Drain

Parameters

| Model | Dia(mm) | Effective L(mm) | Baskets | Volume (CBM) | Design Te.(Degree.C) | Design Pre. (MPA) | Test Pre.(Mpa) |

| WI-1002 | 1000 | 1800 | 2 | 1.65 | 147 | 0.35 | 0.44 |

| WI-1003 | 1000 | 2400 | 3 | 2.12 | 147 | 0.35 | 0.44 |

| WI-1203 | 1200 | 3000 | 3 | 3.78 | 147 | 0.35 | 0.44 |

| WI-1204 | 1200 | 3600 | 4 | 4.45 | 147 | 0.35 | 0.44 |

| WI-1205 | 1200 | 4500 | 5 | 5.48 | 147 | 0.35 | 0.44 |

| WI-1403 | 1400 | 3000 | 3 | 8.2 | 147 | 0.35 | 0.44 |

| WI-1404 | 1400 | 4000 | 4 | 6.77 | 147 | 0.35 | 0.44 |

| WI-1405 | 1400 | 5000 | 5 | 8.31 | 147 | 0.35 | 0.44 |