- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220

-

Dimension(L*W*H):

-

sized

-

Weight:

-

KG

-

Installation:

-

Engineer Guide

-

Color:

-

Customer's Requirements

-

Spare Parts Supply:

-

Lifelong Time

-

Application:

-

Mining

-

Recovery rate:

-

95-98%

-

Certification:

-

ISO

-

Price:

-

Negotible

-

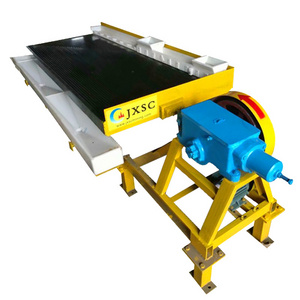

Product name:

-

gold shaking table

-

Keywords:

-

Mining Shaker Table Small Size Gravity Shaking Table Price For Sale

-

Name:

-

Laboratory Gold Separating Machine

Quick Details

-

Production Capacity:

-

98

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XKJ

-

Voltage:

-

220

-

Dimension(L*W*H):

-

sized

-

Weight:

-

KG

-

Installation:

-

Engineer Guide

-

Color:

-

Customer's Requirements

-

Spare Parts Supply:

-

Lifelong Time

-

Application:

-

Mining

-

Recovery rate:

-

95-98%

-

Certification:

-

ISO

-

Price:

-

Negotible

-

Product name:

-

gold shaking table

-

Keywords:

-

Mining Shaker Table Small Size Gravity Shaking Table Price For Sale

-

Name:

-

Laboratory Gold Separating Machine

Information

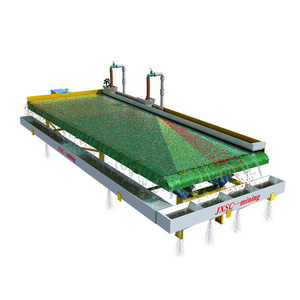

Mining equipment shakingtable is one of the main equipment of gravity concentration. This table mainly by the head of

a bed, motor, adjustable slope, bed, ore groove, groove, reflex and lubrication systems of eight parts. According to the

mine in different position, shaking table can be divided into right and left shaking table two forms. The right table feed position for shaking organizations on the right, the left table to mine position on the left.

Working principles

Shake table is on the lean table board with raffles. The ore material is fed in by the feeding chute upper table board; meanwhile,

the water is fed by water feeder transversely. Under the impact of vibrating wave, the materials go on vertical and horizontal

movement as per the different proportion and granularity. The ore material with different proportion and granularity move

down in laddershipped state along with their own movement, then discharge from the fine concentrate end and tailings end,

finally they are separated out to fine concentrate, middle concentrate and tailings.

Advantages

1. Get concentrate and gangue at one time

2. Fine water-resistance, chemical resistance, corrosion resistance, abrasion resistance, etc;

3. We can simplify the repair and painting process, which directly reduces the maintenance cost, greatly increases recovery

rate, and prolongs the life of ore concentration tables.

4. High enrichment ratio, good selection effect, easy operation

5. Low energy consumption, competitive price

| Model |

6-s 4500 |

6-s 3000 |

6-s 2100 |

6-s 1100 |

|||

| Deck type | coase deck | fine deck | slurry deck | three type of decks optional | |||

| Beneficiation area(m 2 ) | 7.6 | 7.6 | 7.6 | 4.08 | 1.95 | 0.5 | |

|

Deck size (mm) |

Length | 4500 | 4500 | 4500 | 3000 | 2100 | 1100 |

| Transmission width | 1850 | 1850 | 1850 | 1320 | 1050 | 500 | |

| Concentrate width | 1550 | 1550 | 1550 | 1100 | 850 | 430 | |

| Stroke(mm) | 16-22 | 11-16 | 11-16 | 6-30 | 12-28 | 9-17 | |

| Frequency of stroke (r/min) | 220 | 250 | 250 | 210-320 | 250-450 | 280-460 | |

| Max feeding size(mm) | 2 | 0.5 | 0.5 |

sand-2 slurry-0.1 |

sand-2 slurry-0.074 |

sand-2 slurry-0.074 |

|

| Water consumption(t/h) | 0.7-1 | 0.4-0.7 | 0.4-0.7 | 0.3-1.5 | 0.2-1 | 0.1-0.5 | |

| Slope(°) | 0-5 | 0-10 | 0-8 | 0-8 | |||

| Motor power(kW) | 1.1 |

0.5 |

|||||

Note:

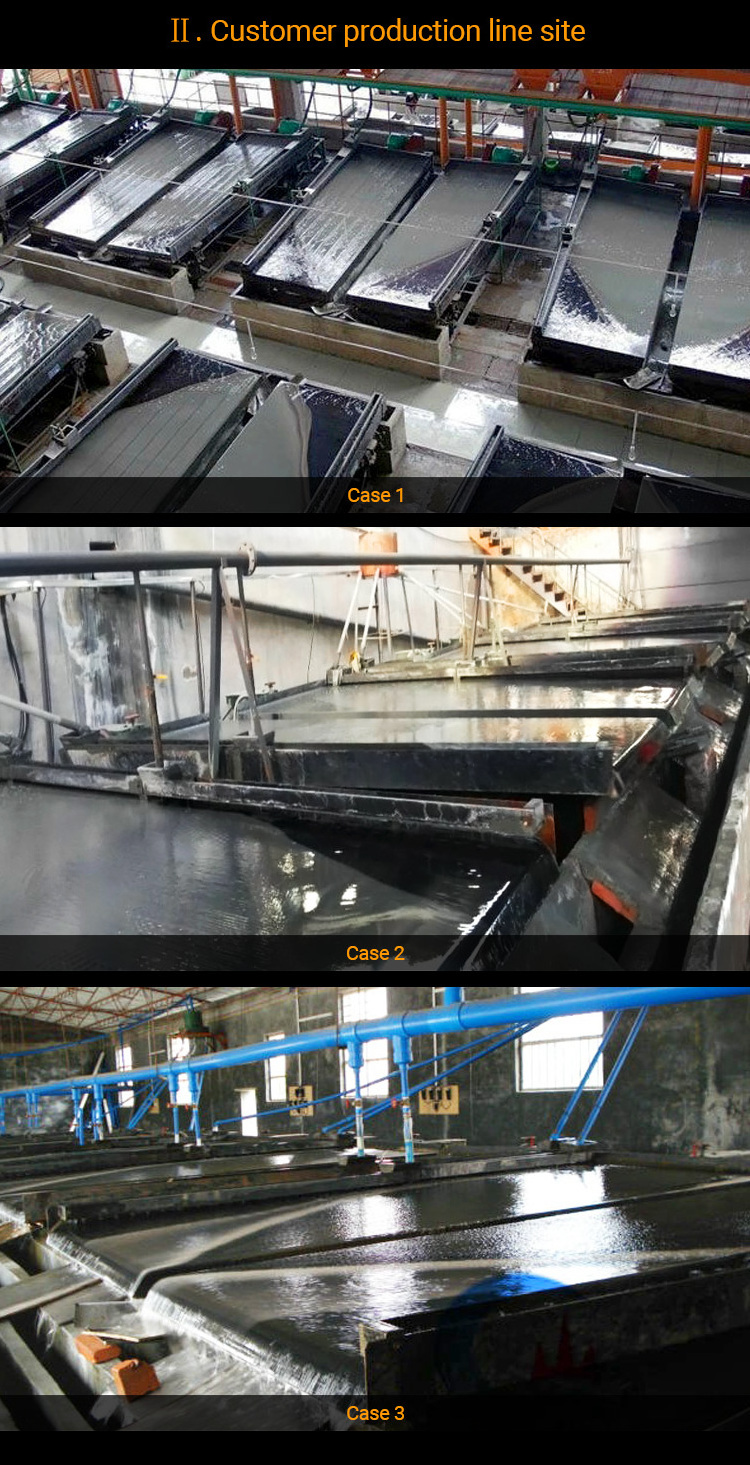

The 6-s shaking table is one of the main equipment for gravity dressing, widely used in the separation of tungsten, tin, tantalum, niobium, iron, manganese, chromium, titanium, bismuth, lead, gold and other rare metals and precious metal ores, but also can be used in coal mines.

A: 1.Total payment lower than 3000USD : 100% payment by T/T before delivery.

2.Total payment higher than 3000USD: 30% prepayment by T/T , after the seller finish the production process and buyer verify the machine , 70% balance should paid before delivery.

3.Alibaba trade assurance L/C is also acceptable in special conditions.

A: 1. The delivery time is within 20-30 working days.

2. But if the project is very large and clients have some special requirement about the equipment, the delivery time will be extened.

A: 1. Africa : 30-45 days

Asia : 5-25 days

America : 15-40 days

Europe : 30-40 days

A: 1. Our machine warranty period is 1 year.

2. Wearing parts and problem coursed by worker's wrong operation are not included.

A: Of course. Please give us your details about project, raw material, the capacity, max feeding size, the output size, the usage of final products, etc.