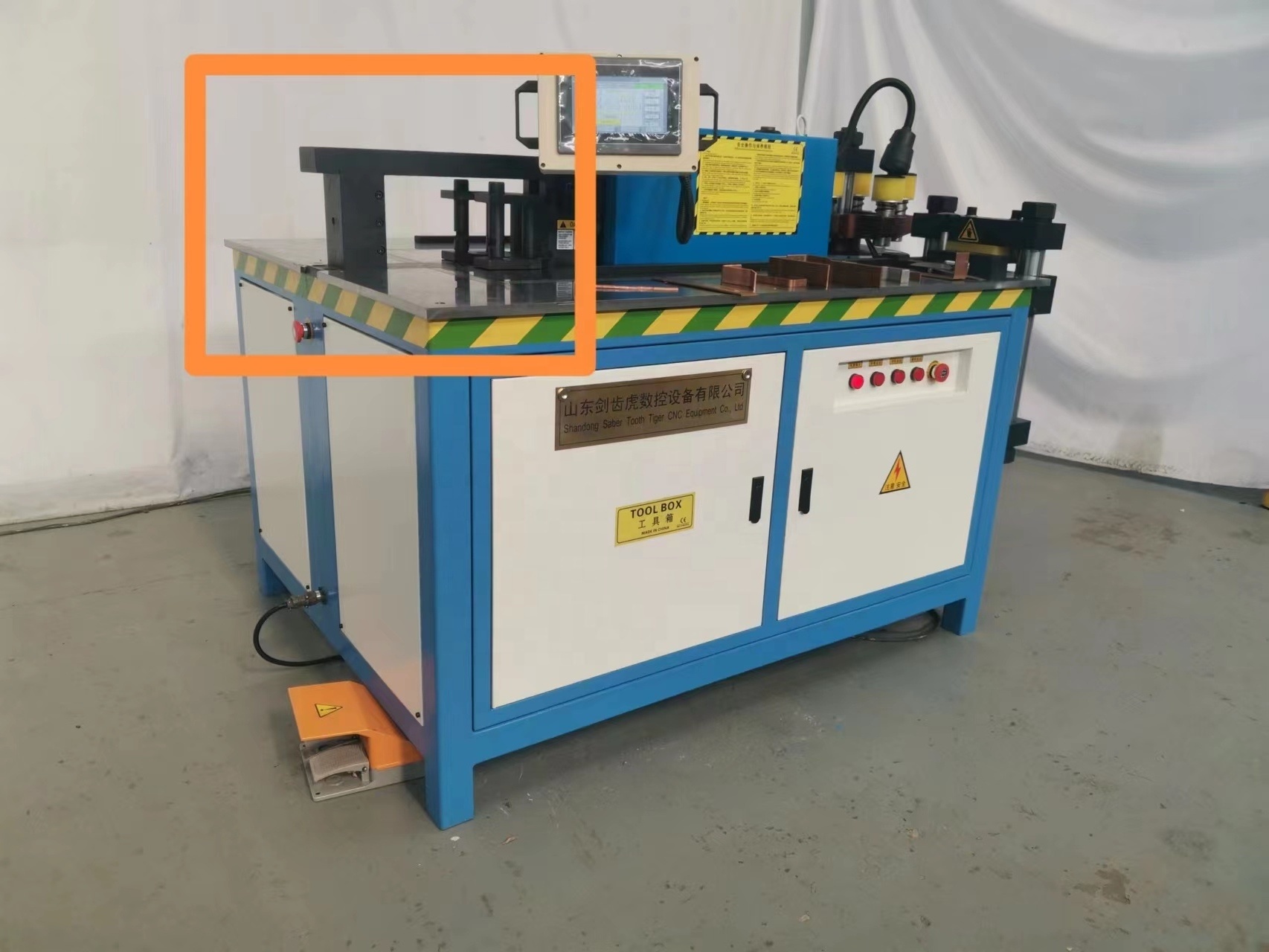

①Adopt the double-column and double-knife shear structure.

②The upper and lower knives are installed in a vertical and parallel way,which ensures the cutting edge is flat,burr free and waste free.

③2 limit switches. (foot switch & press button).

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Saber tooth tiger

-

Voltage:

-

220/380v

-

Dimension(L*W*H):

-

1800x1500x1500

-

Weight (KG):

-

1800

-

Application:

-

Punching Cutting Bending

-

Processing material:

-

Copper Aluminum Bus Bar

-

MOQ:

-

1set

-

Power:

-

3*4kw/3*5.5KW

-

Max Thickness:

-

18mm

-

Delivery time:

-

3 Days

Quick Details

-

Max. Thickness (mm):

-

18 mm

-

Max. Width (mm):

-

260 mm

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Saber tooth tiger

-

Voltage:

-

220/380v

-

Dimension(L*W*H):

-

1800x1500x1500

-

Weight (KG):

-

1800

-

Application:

-

Punching Cutting Bending

-

Processing material:

-

Copper Aluminum Bus Bar

-

MOQ:

-

1set

-

Power:

-

3*4kw/3*5.5KW

-

Max Thickness:

-

18mm

-

Delivery time:

-

3 Days

Products Description

Structural features

six-mode punching unit

punching die and sample

Punching unit:

①Adopt the six-mode integral turntable(the mold installation hole is processed by the CNC machining center,with high precision)

②No need to change the mold frequently during use,which improves the working efficiency.

②No need to change the mold frequently during use,which improves the working efficiency.

③No pressing mark on the workpiece surface.

④Can punch non-standard holes with special dies, for example, square hole, oval hole etc.

④Can punch non-standard holes with special dies, for example, square hole, oval hole etc.

Bending unit:

①Closed bending, the output point and the force point are connected by a beam with a thickness of 50mm.

②To complete the horizontal bending and vertical bending by replacing the die.

③Angle bending can be performed by entering the bending angle and the thickness of copper and aluminum bars.

④Uses Siemens PLC control system, the bending precision is high.

⑤303 and 503 have double deck worktables.301 and 501 have only one workbench.

⑥303 has two types: open bending and closed bending. Open bending has better efficiency and is more conducive to processing copper bars.

②To complete the horizontal bending and vertical bending by replacing the die.

③Angle bending can be performed by entering the bending angle and the thickness of copper and aluminum bars.

④Uses Siemens PLC control system, the bending precision is high.

⑤303 and 503 have double deck worktables.301 and 501 have only one workbench.

⑥303 has two types: open bending and closed bending. Open bending has better efficiency and is more conducive to processing copper bars.

301/501

303/503

303 Open Bending

Shearing/cutting unit:

Main component:

Siemens PLC

AC contactor, thermal replay (Schneider

Product Paramenters

|

Parameter

|

|

ZTMX-301K

|

ZTMX-303K

|

ZTX-501K

|

ZTMX-503K

|

|

|

Punching

|

Max power(KN)

|

350

|

350

|

500

|

500

|

|

|

|

Punching Diameter(mm)

|

φ4.3-φ25

|

φ4.3-φ25

|

φ4.3-φ32

|

φ4.3-φ32

|

|

|

|

Max Thickness(mm)

|

15

|

15

|

18

|

18

|

|

|

Shearing/cutting

|

Max Width(mm)

|

160

|

160

|

260

|

260

|

|

|

|

Max Thickness(mm)

|

15

|

15

|

18

|

18

|

|

|

Bending

|

Max Power(KN)

|

350

|

350

|

550

|

550

|

|

|

|

Max Width(mm)

|

160

|

160

|

260

|

260

|

|

|

|

Max Thickness(mm)

|

15

|

15

|

18

|

18

|

|

|

Vertical bending

|

Max Size

|

120*10

|

120*10

|

120*10

|

120*10

|

|

|

Power of motor

|

(KW)

|

1x4

|

3x4

|

1×5.5

|

3×5.5

|

|

|

Weight

|

(T)

|

1.3

|

1.5

|

1.8

|

2.2

|

|

|

Size of worktable

|

First floor(mm)

|

1440x1240

|

1440x1240

|

1540x1450

|

1540x1450

|

|

|

|

Second floor(mm)

|

|

890x500

|

|

1000x500

|

|

|

Parameter

|

|

ZTMX-301

|

ZTMX-303

|

|

|

Punching

|

Max power(KN)

|

350

|

350

|

|

|

|

Punching Diameter(mm)

|

φ4.3-φ25

|

φ4.3-φ25

|

|

|

|

Max thickness(mm)

|

15

|

15

|

|

|

Shearing/Cutting

|

Max width(mm)

|

160

|

160

|

|

|

|

Max thickness(mm)

|

15

|

15

|

|

|

Bending

|

Max power(KN)

|

350

|

350

|

|

|

|

Max width(mm)

|

160

|

160

|

|

|

|

Max thickness(mm)

|

15

|

15

|

|

|

Vertical bending

|

Max size

|

120*10

|

120*10

|

|

|

Power of Motor

|

(KW)

|

1x4

|

3x4

|

|

|

Weight of machine

|

(T)

|

1.3

|

1.5

|

|

|

Outline Dimension

|

(mm)

|

1800x1400x1300

|

1800x1400x1400

|

|

|

Size of worktable

|

First floor(mm)

|

1440X1240

|

1440X1240

|

|

|

|

Second floor(mm)

|

|

890x500

|

|

|

Shearing,Punching and Bending work simultaneously

|

|

|

Yes

|

|

|

Parameter

|

|

ZTMX-501

|

ZTMX-503

|

|

|

Punching

|

Max power(KN)

|

500

|

500

|

|

|

|

Punching Diameter(mm)

|

φ4.3-φ32

|

φ4.3-φ32

|

|

|

|

Max thickness(mm)

|

18

|

18

|

|

|

Shearing/Cutting

|

Max width(mm)

|

260

|

260

|

|

|

|

Max thickness(mm)

|

18

|

18

|

|

|

Bending

|

Max power(KN)

|

550

|

550

|

|

|

|

Max width(mm)

|

260

|

260

|

|

|

|

Max thickness(mm)

|

18

|

18

|

|

|

Vertical bending

|

Max size

|

120*10

|

120*10

|

|

|

Power of Motor

|

(KW)

|

1×5.5

|

3×5.5

|

|

|

Weight of machine

|

(T)

|

1.8

|

2.2

|

|

|

Outline Dimension

|

(mm)

|

2000x1500x1400

|

2000x1500x1500

|

|

|

Size of worktable

|

First floor(mm)

|

1540x1450

|

1540x1450

|

|

|

|

Second floor(mm)

|

|

1000x500

|

|

|

Shearing,Punching and Bending work simultaneously

|

|

|

Yes

|

|

Samples

Accessories

Product packaging

Certifications

FAQ

Q1: How is quality ensured about the busbar processing machine?

Our factory passed the ISO-9001 and CE certification. For products, the company provides 1-year warranty service

Our factory passed the ISO-9001 and CE certification. For products, the company provides 1-year warranty service

Q2: Can customized machines be purchased?

Yes, We support product customization.

Yes, We support product customization.

Q3: How many years of production experience and customer market experience do you have?

We have more than 10 years of production experience, we are agents and end customers direct sales company.

We have more than 10 years of production experience, we are agents and end customers direct sales company.

Q4: How about the payment term?

30% advance payment, final payment before delivery, full payment for delivery.

30% advance payment, final payment before delivery, full payment for delivery.

Hot Searches