- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Optic

-

Dimension(L*W*H):

-

1100x700x1150mm

-

Year:

-

2022

-

Weight (KG):

-

260 KG

-

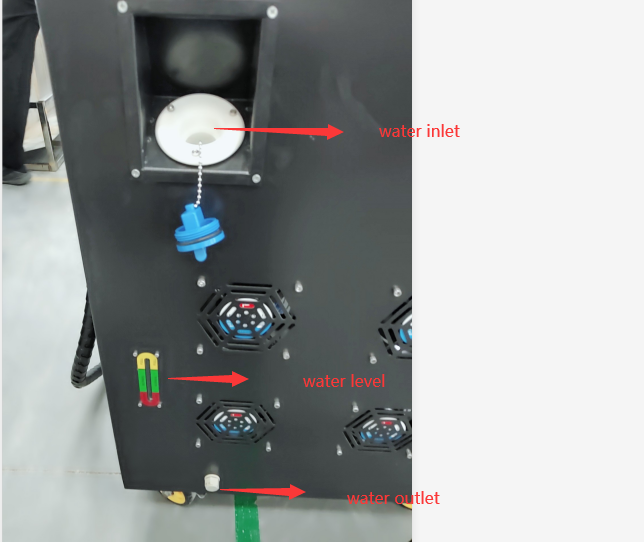

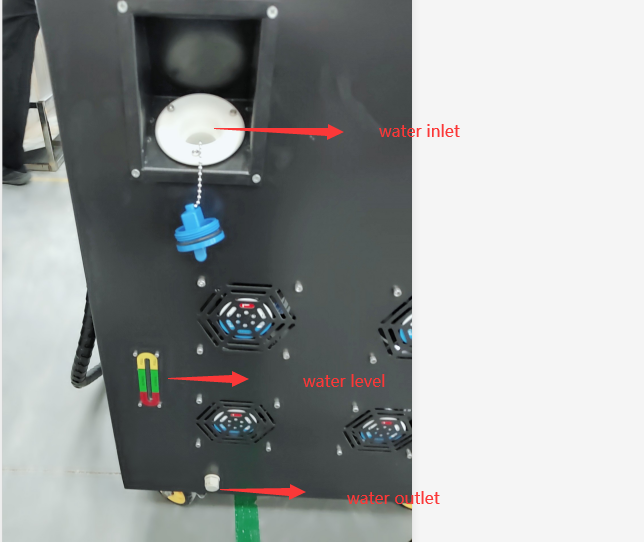

Cooling method:

-

Water Cooling

-

Clean Width:

-

10-100mm

-

Product name:

-

Pulse laser cleaning machine

-

Material:

-

Metal Materials

-

Cleaning Type:

-

Handheld

-

Clean way:

-

Non-touch Laser Cleaning

-

Repeat frequency:

-

20-200KHz

-

Working temperature:

-

5℃~40℃

-

Power supply:

-

220V±10%,50/60Hz /380V±10%,50/60Hz

Quick Details

-

Power:

-

200W, 100W, 500W, 300w

-

Laser Type:

-

Fiber Laser

-

Laser Source Brand:

-

RECI

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Optic

-

Dimension(L*W*H):

-

1100x700x1150mm

-

Year:

-

2022

-

Weight (KG):

-

260 KG

-

Cooling method:

-

Water Cooling

-

Clean Width:

-

10-100mm

-

Product name:

-

Pulse laser cleaning machine

-

Material:

-

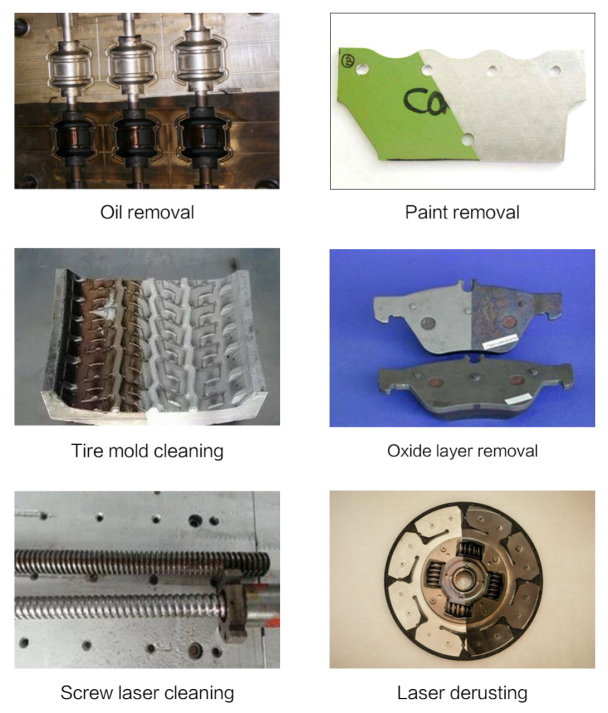

Metal Materials

-

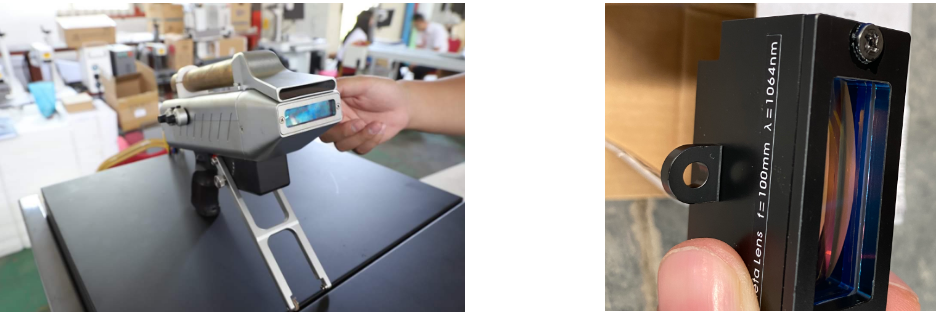

Cleaning Type:

-

Handheld

-

Clean way:

-

Non-touch Laser Cleaning

-

Repeat frequency:

-

20-200KHz

-

Working temperature:

-

5℃~40℃

-

Power supply:

-

220V±10%,50/60Hz /380V±10%,50/60Hz

Product Overview

Fiber laser cleaning machine

Traditional cleaning industry has a variety of cleaning methods, mostly using chemical agents and mechanical cleaning methods.

Nowadays environmental protection laws and regulations are becoming more and more stringent, people's awareness of environmental protection and safety is increasing, chemicals can be used in the industrial production became less and less. Laser cleaning has the characteristics of no grinding, no contact, no thermal effect and suitable for all kinds of materials, which is considered to be the most reliable and effective solution.At the same time, laser cleaning can solve the traditional cleaning methods can not solve the problem.

Fiber laser cleaning machine working principle is detaied as below.

The pulsed Nd:YAG laser cleaning process depends on the characteristics of the optical pulse produced by the laser, based on the optical physical reaction caused by the interaction between the high-intensity beam, the short-pulse laser and the pollution layer.Its physical principle can be summarized as follows:

A) The beam emitted by the laser is absorbed by the contaminated layer on the surface to be treated.

B) The absorption of large energy forms a rapidly expanding plasma (highly ionized unstable gas), generating shock waves.

C) The shock wave causes the pollutants to fragment and be removed.

D) The light pulse width must be short enough to avoid the heat accumulation that destroys the treated surface.

E) Experiments show that when there is oxide on the metal surface, plasma is generated on the metal surface.

Plasmas are produced only if the energy density is above a threshold, which depends on the contaminant or oxide layer being removed.This threshold effect is important for effective cleaning without compromising the safety of the substrate.There is a second threshold for the emergence of plasma.If the energy density exceeds this threshold, the substrate material will be destroyed.In order to effectively clean the base material safely, the laser parameters must be adjusted according to the situation so that the energy density of the light pulse is strictly between the two thresholds.

Nowadays environmental protection laws and regulations are becoming more and more stringent, people's awareness of environmental protection and safety is increasing, chemicals can be used in the industrial production became less and less. Laser cleaning has the characteristics of no grinding, no contact, no thermal effect and suitable for all kinds of materials, which is considered to be the most reliable and effective solution.At the same time, laser cleaning can solve the traditional cleaning methods can not solve the problem.

Fiber laser cleaning machine working principle is detaied as below.

The pulsed Nd:YAG laser cleaning process depends on the characteristics of the optical pulse produced by the laser, based on the optical physical reaction caused by the interaction between the high-intensity beam, the short-pulse laser and the pollution layer.Its physical principle can be summarized as follows:

A) The beam emitted by the laser is absorbed by the contaminated layer on the surface to be treated.

B) The absorption of large energy forms a rapidly expanding plasma (highly ionized unstable gas), generating shock waves.

C) The shock wave causes the pollutants to fragment and be removed.

D) The light pulse width must be short enough to avoid the heat accumulation that destroys the treated surface.

E) Experiments show that when there is oxide on the metal surface, plasma is generated on the metal surface.

Plasmas are produced only if the energy density is above a threshold, which depends on the contaminant or oxide layer being removed.This threshold effect is important for effective cleaning without compromising the safety of the substrate.There is a second threshold for the emergence of plasma.If the energy density exceeds this threshold, the substrate material will be destroyed.In order to effectively clean the base material safely, the laser parameters must be adjusted according to the situation so that the energy density of the light pulse is strictly between the two thresholds.

Packing&Shipping

Regarding to lead time We received your iniital payment, we install and inspect laser welding machine within 5 working days. If you order over more than 10 pcs that lead time will be take 15 working days.Mostly, our customers ship the machine by sea.It can help you save more shipping cost.

Company Introduction

Optic Technology (Shenzhen) Co., Ltd. is a laser equipment company integrating research,development,production and sales. OPTIC LASER is located in China's special economic zone, an international metropolis - Shenzhen.Products from OPTIC LASER have passed the CE certification system, products for global sales,exported to North America, Western Europe, South Asia, South America, the Middle East and more than 80 countries and regions. Optic Technology (Shenzhen) Co., Ltd is dedicated to providing its customers with laser welding machines, laser marking machines, laser cutting machines and other industrial automation equipment. The products are widely used in aerospace, automotive, steel and metallurgy, shipbuilding, computer manufacturing, and communications networks, electronic circuits, integrated circuits, precision instruments, building materials, apparel, urban lighting, gold and silver jewelry, craft gifts and other industries.

Regarding to lead time We received your iniital payment, we install and inspect laser welding machine within 5 working days. If you order over more than 10 pcs that lead time will be take 15 working days.Mostly, our customers ship the machine by sea.It can help you save more shipping cost.

Company Introduction

Optic Technology (Shenzhen) Co., Ltd. is a laser equipment company integrating research,development,production and sales. OPTIC LASER is located in China's special economic zone, an international metropolis - Shenzhen.Products from OPTIC LASER have passed the CE certification system, products for global sales,exported to North America, Western Europe, South Asia, South America, the Middle East and more than 80 countries and regions. Optic Technology (Shenzhen) Co., Ltd is dedicated to providing its customers with laser welding machines, laser marking machines, laser cutting machines and other industrial automation equipment. The products are widely used in aerospace, automotive, steel and metallurgy, shipbuilding, computer manufacturing, and communications networks, electronic circuits, integrated circuits, precision instruments, building materials, apparel, urban lighting, gold and silver jewelry, craft gifts and other industries.

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Data

|

|

1

|

Products Name

|

Fiber Laser Cleaning Machine

|

|

2

|

Laser Wavelength

|

1064nm

|

|

3

|

Repeat frequency

|

20-200KHz

|

|

4

|

Cooling method

|

Air cooling

|

|

5

|

Scan width

|

20-80mm

|

|

6

|

Laser head type

|

Handheld

|

|

7

|

Working temperature

|

5°C-40°C

|

|

8

|

Power supply

|

220V±10%,50/60Hz

|

FAQ

Q1: Are you trading company or manufacturer ?

A: We are factory. Our factory in Shen Zhen City, China, Welcome to visit our factory!

Q2: How long is your delivery time?

A: Generally it is 3-5 days if the goods are in stock. or it is 5-10 days if the goods are not in stock, it is according to

quantity.

Q3: What is your terms of payment ?

30% T/T in advance ,balance before shipment.

Q4: I know nothing about this machine, what type of machine should I choose?

A: We will help you choose the suitable machine and share you the solution; you can share us what material will you welding and the size & depth of welding.

Q5: When I got this machine, but I don’t know how to use it. What should I do?

A: We will send operation and manual video for the machine. Our engineer will do training online. If needed, you can send the operator to our factory for training.

Q6: If some problems happen to this machine, what should I do?

A: We provide two years machine warranty. During the two-year warranty, in case any problem for the machine, we will provide the parts free of charge (except for artificial damage). After the warranty, we still provide whole lifetime service. So any doubts, just let us know, we will give you solutions.

Q7: What’s package, will it protect the products?

A: We have 3 layers package. For the outside, we adopt wooden cases free of fumigation. In the middle, the machine is covered by foam, to protect the machine from shaking. For the inside layer, the machine is covered by waterproof plastic film.

A: We are factory. Our factory in Shen Zhen City, China, Welcome to visit our factory!

Q2: How long is your delivery time?

A: Generally it is 3-5 days if the goods are in stock. or it is 5-10 days if the goods are not in stock, it is according to

quantity.

Q3: What is your terms of payment ?

30% T/T in advance ,balance before shipment.

Q4: I know nothing about this machine, what type of machine should I choose?

A: We will help you choose the suitable machine and share you the solution; you can share us what material will you welding and the size & depth of welding.

Q5: When I got this machine, but I don’t know how to use it. What should I do?

A: We will send operation and manual video for the machine. Our engineer will do training online. If needed, you can send the operator to our factory for training.

Q6: If some problems happen to this machine, what should I do?

A: We provide two years machine warranty. During the two-year warranty, in case any problem for the machine, we will provide the parts free of charge (except for artificial damage). After the warranty, we still provide whole lifetime service. So any doubts, just let us know, we will give you solutions.

Q7: What’s package, will it protect the products?

A: We have 3 layers package. For the outside, we adopt wooden cases free of fumigation. In the middle, the machine is covered by foam, to protect the machine from shaking. For the inside layer, the machine is covered by waterproof plastic film.

Carine Tan

Sales Manager

OPTIC Technology (Shenzhen) CO., Ltd

Email: optic106@optic-tech.cn

Facebook/Whatsapp/WeChat: +86 19129596091

Website: www.opticlaser.net

Sales Manager

OPTIC Technology (Shenzhen) CO., Ltd

Email: optic106@optic-tech.cn

Facebook/Whatsapp/WeChat: +86 19129596091

Website: www.opticlaser.net

Hot Searches