- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

X-Mag

-

Processing Service:

-

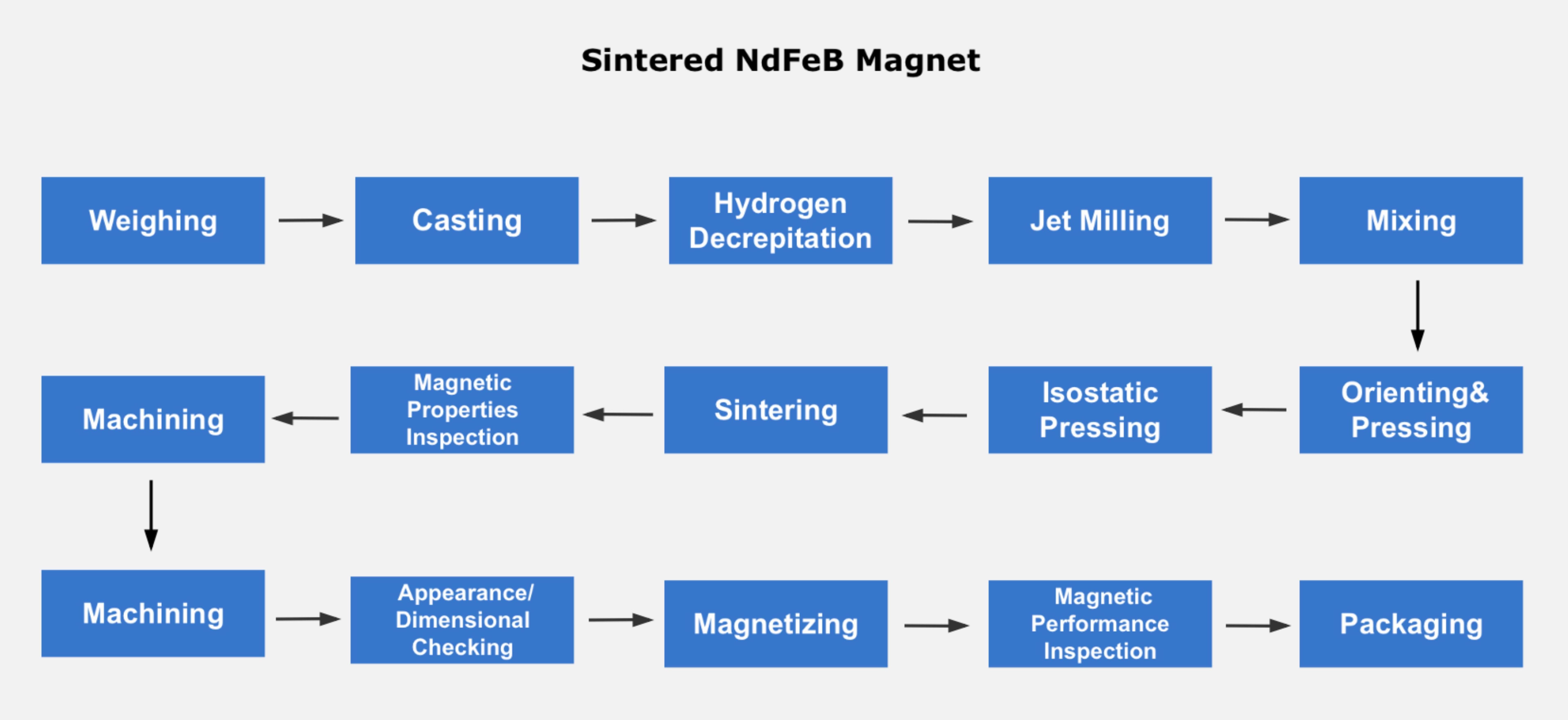

Weighing, Casting, Hydrogen Decrepitation, Jet Milling, Mixing, Orienting&Pressing, Isostatic Pressing, Sintering, Magnetic Properties Inspectiom, Machining, Magnetizing

-

Delivery Time:

-

20-30 days

-

Coating:

-

Nickle, Zinc, Epoxy, Parylene, Gold, Ag, Al, PTFE, Everlube and etc.

-

Certification:

-

IATF16949, AS9100, ISO9001, ISO14001, IS045001, GJB9001B

-

Quality Assurance:

-

Dimensional, Magnetic properties/performance, Enviromental reliability

-

Magnetism Direction:

-

Length, Width, Thickness, Axial, Diameter, Customized

-

Density:

-

7.45 g/cm3

-

Max Working Temperature:

-

80-250 ℃

-

Coercivity:

-

Hcj ≥ 39kOe

-

Remanence:

-

10.5kGs ≤ Br ≤ 15.0kGs

Quick Details

-

Tolerance:

-

±0.1mm, tighter as customized

-

Grade:

-

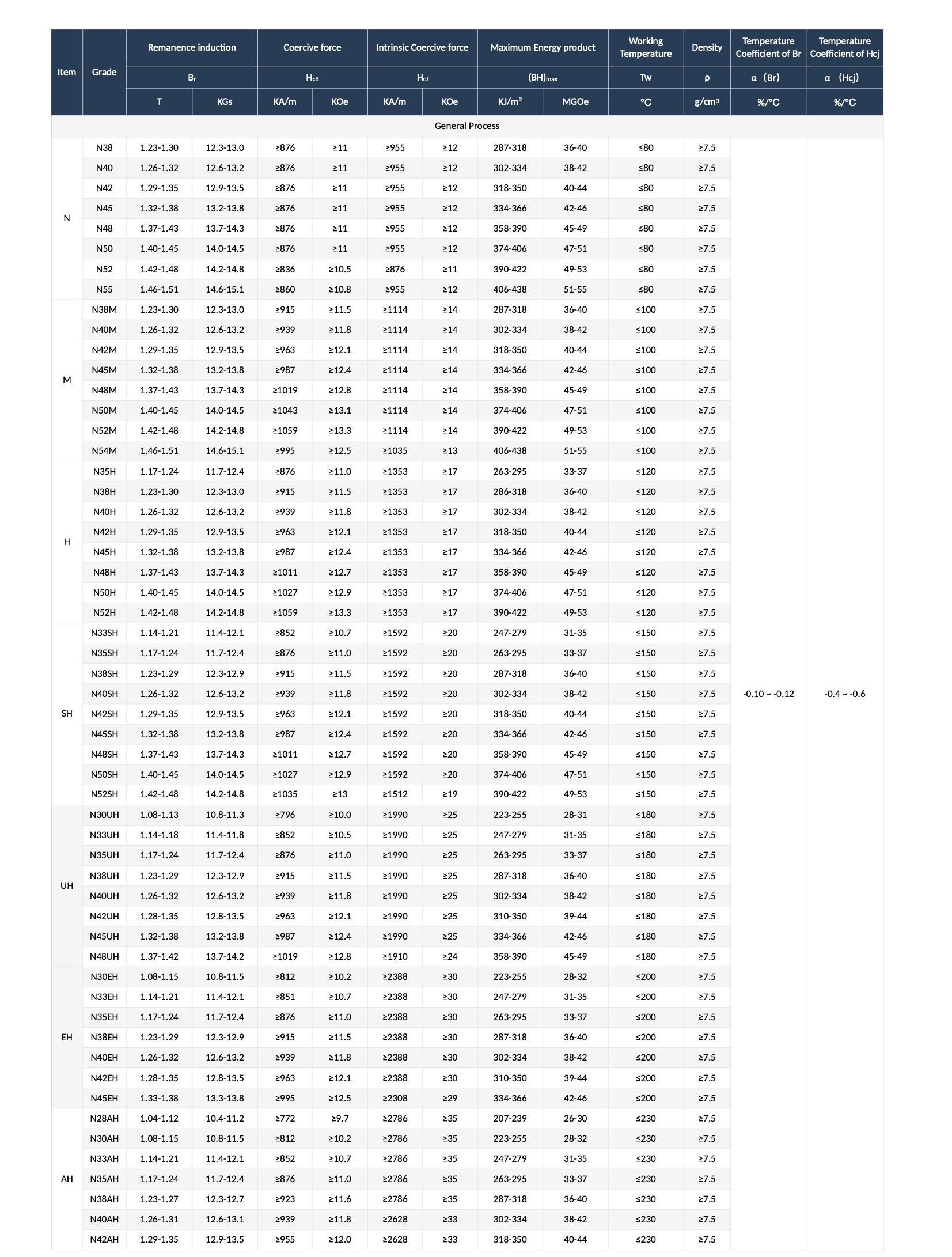

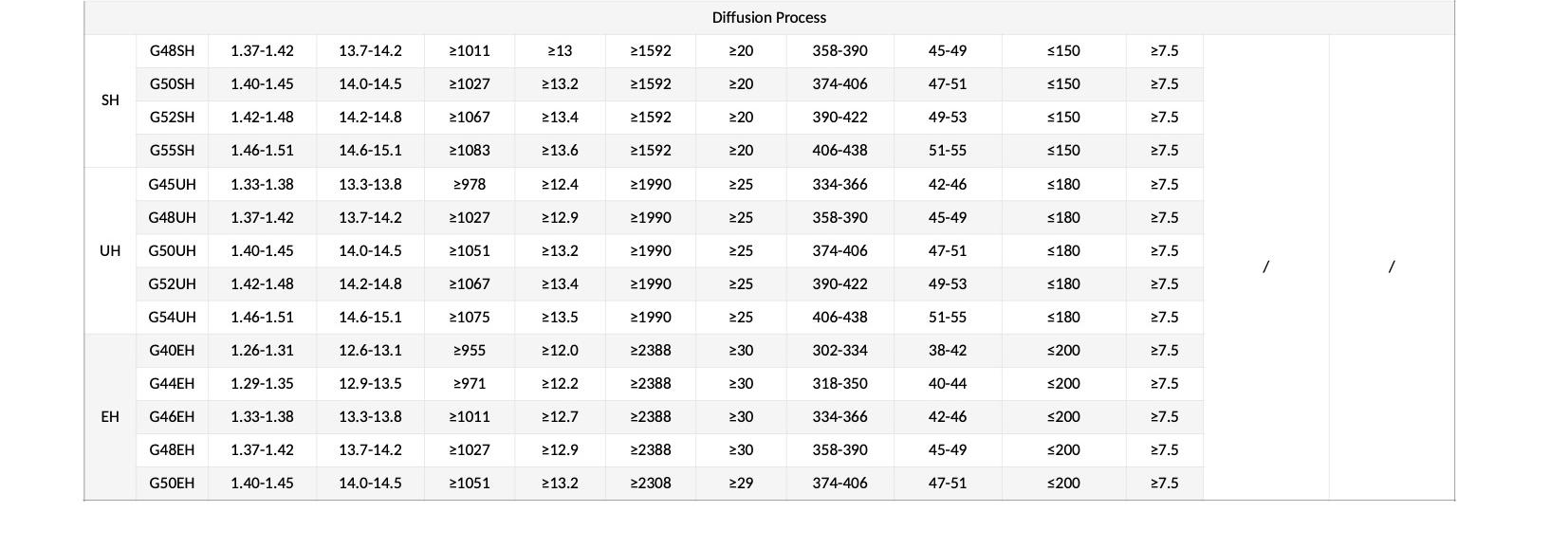

N35~N38VH

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

X-Mag

-

Processing Service:

-

Weighing, Casting, Hydrogen Decrepitation, Jet Milling, Mixing, Orienting&Pressing, Isostatic Pressing, Sintering, Magnetic Properties Inspectiom, Machining, Magnetizing

-

Delivery Time:

-

20-30 days

-

Coating:

-

Nickle, Zinc, Epoxy, Parylene, Gold, Ag, Al, PTFE, Everlube and etc.

-

Certification:

-

IATF16949, AS9100, ISO9001, ISO14001, IS045001, GJB9001B

-

Quality Assurance:

-

Dimensional, Magnetic properties/performance, Enviromental reliability

-

Magnetism Direction:

-

Length, Width, Thickness, Axial, Diameter, Customized

-

Density:

-

7.45 g/cm3

-

Max Working Temperature:

-

80-250 ℃

-

Coercivity:

-

Hcj ≥ 39kOe

-

Remanence:

-

10.5kGs ≤ Br ≤ 15.0kGs

Product Description

|

Composite

|

NdFeB Magnets/Neodymium Magnets

|

|

Place of Origin

|

Zhejiang, China(Mainland)

|

|

Applications

|

Automotive, Medical, Consumer Electronics, Military, Aerospace and etc.

|

|

Processing Service

|

Weighing, Casting, Hydrogen Decrepitation, Jet Milling, Mixing, Orienting&Pressing, Isostatic Pressing, Sintering, Magnetic Properties Inspection, Machining, Magnetizing, Magnetic Performance Inspection, etc.

|

|

Size

|

Customized

|

|

Shape

|

Block, Rod, Disc, Ring, Arc, Customized

|

|

Grade

|

N35 to N38VH

|

|

Tolerance

|

±0.1mm, Customized

|

|

Magnetism Direction

|

Length, Width, Thickness, Axial, Diameter, Radial Multi-poles, Customized

|

|

Coating

|

Nickle, Zinc, Epoxy, Parylene, Gold, Ag, Al, PTFE, Everlube and etc.

|

|

Density

|

7.45 g/cm³

|

|

Sample

|

Available

|

Production Process

Packing & Delivery

Packing:

To better ensure the safety of your goods, professional, environmentally friendly, convenient, and efficient packaging services will be provided.

Delivery:

Goods can be delivered to customers by Sea, Air and International couriers (Fedex,UPS and DHL etc).

We have stable logistics forwarder partners and can also send goods through forwarders nominated by customers.

We have stable logistics forwarder partners and can also send goods through forwarders nominated by customers.

Flexible Payment

We accept T/T, Paypal, Western Union, ESCROW and L/C and others which are efficient for our trading.

Why Choose Us

Company profile:

With over 20 years of experience in the design, R&D, and manufacturing of all types of magnetic materials, powder injection moulding components, magnetic assemblies, rotors, stators, motors, modules, sophisticated magnetic systems, magnetizing and measuring systems, X-mag provides one stop and turnkey solutions to the most recognizable customers worldwide in industries of automotive, consumer electronics, appliance, security, sensing, medical, aerospace, defense and others on a global scale.

Our office Team:

Here are photos of our office team.

Our manufacturing sites:

Here are photos for some of our manufacturing sites.

Our workshops:

Our Workshops for Sintered NdFeB Magnet.

Quality Control:

X-mag strictly controls product quality from incoming material testing, through in-process inspection, final product inspection and packaging inspection. We have a variety of testing equipment to ensure that the products meet the customer’s stringent requirements.We have strict quality control in IQC, IPQC, OQC with advanced equipments.

Our Services

We are committed to your success and your positive comments on us.

FAQ

Q: Are you trader or manufacturer?

A: We are manufacturer. We have our own manufacturing sites for different magnetic materials or magnetic components. Through manufacturing vertical integration, we provide one stop and turnkey solutions to the most recognizable customers worldwide in industries of automotive, consumer electronics, appliance, security, sensing, medical, aerospace, defense and others on a global scale.

Q: Are all samples free?

A: If there is stock, the sample could be free.

Q: What's the payment method?

A: T/T, L/C, western Union, D/P,D/A, MoneyGram, etc...

Lower than 5000 usd, 100% in advance; more than 5000 usd,30% in advance. Also can be negotiated.

Q: What's the lead time?

A: 2 weeks for quick samples, 30-35 days for standard production.

Q: What's the MOQ?

Q: Are all samples free?

A: If there is stock, the sample could be free.

Q: What's the payment method?

A: T/T, L/C, western Union, D/P,D/A, MoneyGram, etc...

Lower than 5000 usd, 100% in advance; more than 5000 usd,30% in advance. Also can be negotiated.

Q: What's the lead time?

A: 2 weeks for quick samples, 30-35 days for standard production.

Q: What's the MOQ?

A: Except sintered ferrite magnet, we usually don’t have MOQ.

Q: What if the goods are damaged?

A: This usually won’t happen, because we have packaging designer who can evaluate the package design for you.

If it happens, we can check the photos for damaged products and find the root cause and give correction plan/suggestion.

Q: How to ensure product quality?

A: We strictly controls product quality from incoming material testing, through in-process inspection, final product

inspection and packaging inspection. We have a variety of testing equipment to ensure that the products meet the customer’s stringent requirements.

We has earned AS9100, IATF16949, ISO9001, ISO14001, ISO45001 certifications.

Q: How to find you in other ways?

A: Our website: http://www.x-magnet.com/

Our LinkedIn page: https://www.linkedin.com/company/x-magnet/.

You are welcome to our manufacturing facilities in China.

Q: What if the goods are damaged?

A: This usually won’t happen, because we have packaging designer who can evaluate the package design for you.

If it happens, we can check the photos for damaged products and find the root cause and give correction plan/suggestion.

Q: How to ensure product quality?

A: We strictly controls product quality from incoming material testing, through in-process inspection, final product

inspection and packaging inspection. We have a variety of testing equipment to ensure that the products meet the customer’s stringent requirements.

We has earned AS9100, IATF16949, ISO9001, ISO14001, ISO45001 certifications.

Q: How to find you in other ways?

A: Our website: http://www.x-magnet.com/

Our LinkedIn page: https://www.linkedin.com/company/x-magnet/.

You are welcome to our manufacturing facilities in China.

Hot Searches