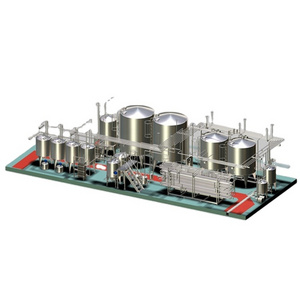

The system adopts the most advanced dry system process. The high temperature and high pressure of can to livestock and poultry

carcasses is preparing sterilization, which will then be completely decomposed into fat and flesh powder after drying, degreasing,

crushing and other procedures.

crushing and other procedures.