- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

3300 mm

-

Throat Depth (mm):

-

50 mm

-

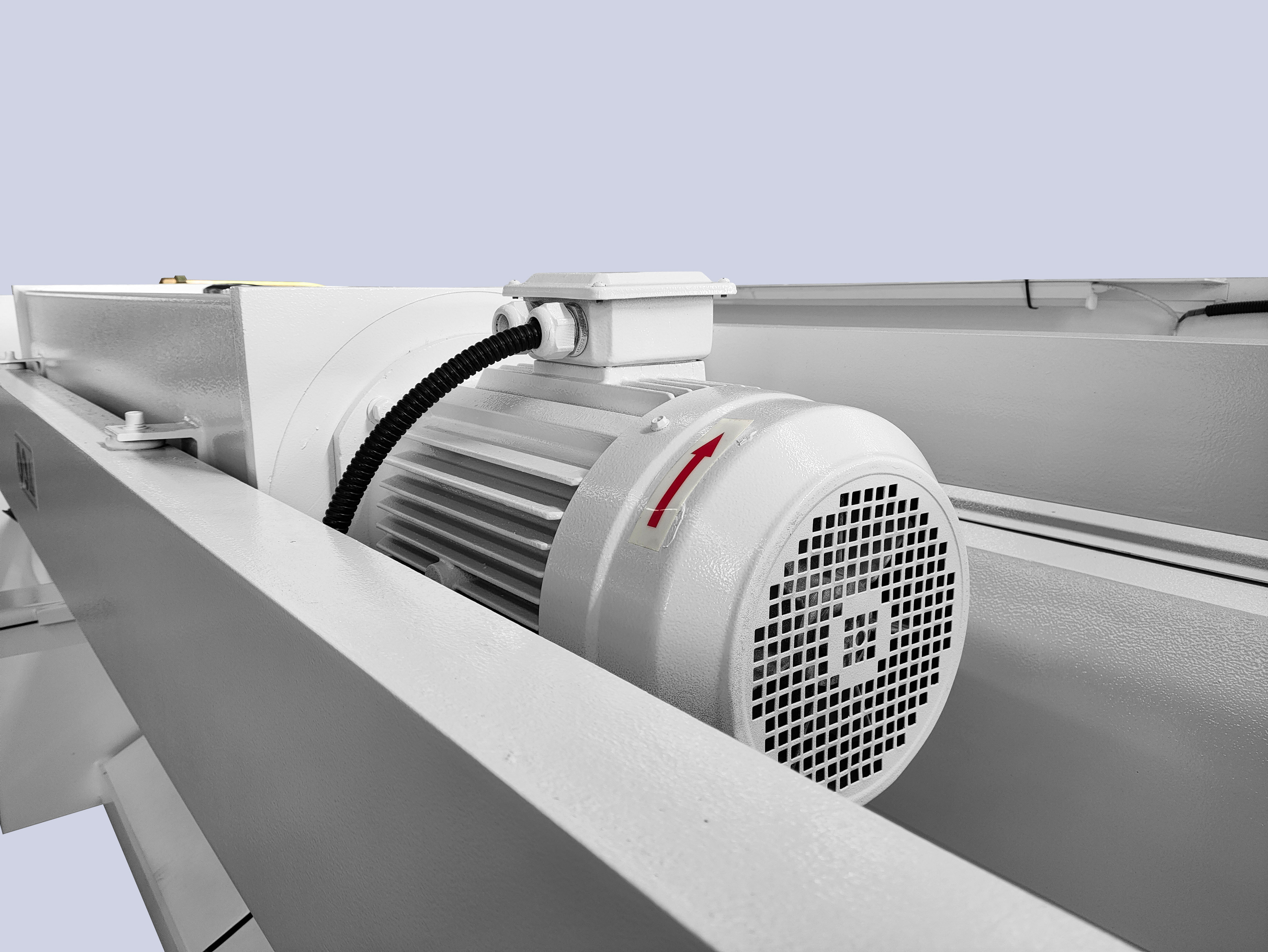

Power (kW):

-

11 kW

-

Weight (KG):

-

8000 KG

-

Place of Origin:

-

ANH

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

3880x2150x2000

-

Year:

-

new

Quick Details

-

Max. Cutting Width (mm):

-

3200

-

Max. Cutting Thickness (mm):

-

10 mm

-

Shearing Angle:

-

1-3

-

Blade Length (mm):

-

3300 mm

-

Throat Depth (mm):

-

50 mm

-

Power (kW):

-

11 kW

-

Weight (KG):

-

8000 KG

-

Place of Origin:

-

ANH

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

3880x2150x2000

-

Year:

-

new

|

Model

|

Shearable

Thickness

(mm)

|

Shearable

Board Width

(mm)

|

Clipping

Angles

(°)

|

Material

strength

(Kn/cm)

|

Backgauge

Stroke

(mm)

|

Times

(T/min)

|

Main Motor

(Kw)

|

Weight

(Ton)

|

Length (mm)

Height (mm)

Width (mm)

|

|

4×2500

|

4

|

2500

|

1°30′

|

≤450

|

20-600

|

16

|

5.5

|

3.4

|

3100×1700×1650

|

|

4×3200

|

4

|

3200

|

1°30′

|

≤450

|

20-600

|

14

|

5.5

|

4

|

3800×1700×1650

|

|

4×4000

|

4

|

4000

|

1°30′

|

≤450

|

20-600

|

10

|

5.5

|

5.6

|

4600×1750×1750

|

|

6×2500

|

6

|

2500

|

1°30′

|

≤450

|

20-600

|

14

|

7.5

|

4.4

|

3100×1750×1700

|

|

6×3200

|

6

|

3200

|

1°30′

|

≤450

|

20-600

|

12

|

7.5

|

5.1

|

3800×1750×1700

|

|

6×4000

|

6

|

4000

|

1°30′

|

≤450

|

20-600

|

8

|

7.5

|

7.6

|

4600×1850×1850

|

|

6×5000

|

6

|

5000

|

1°30′

|

≤450

|

20-600

|

6

|

11

|

12.5

|

5600×2050×1950

|

|

6×6000

|

6

|

6000

|

1°30′

|

≤450

|

20-600

|

5

|

11

|

14.8

|

6600×2120×2230

|

|

8×2500

|

8

|

2500

|

1°30′

|

≤450

|

20-600

|

10

|

11

|

5.3

|

3100×1750×1700

|

|

8×3200

|

8

|

3200

|

1°30′

|

≤450

|

20-600

|

8

|

11

|

6.5

|

3800×1750×1700

|

|

8×4000

|

8

|

4000

|

1°30′

|

≤450

|

20-600

|

8

|

11

|

7.7

|

4600×1850×1850

|

|

8×5000

|

8

|

5000

|

1°30′

|

≤450

|

20-600

|

8

|

15

|

14

|

5600×2100×2000

|

|

8×6000

|

8

|

6000

|

1°30′

|

≤450

|

20-600

|

8

|

15

|

15.8

|

6600×2200×2300

|

|

10×2500

|

10

|

2500

|

2°

|

≤450

|

20-600

|

9

|

15

|

6.5

|

3100×1820×1920

|

|

10×3200

|

10

|

3200

|

2°

|

≤450

|

20-600

|

9

|

15

|

7.7

|

3800×1820×1920

|

|

10×4000

|

10

|

4000

|

2°

|

≤450

|

20-600

|

8

|

15

|

9

|

4600×1900×2000

|

|

10×6000

|

10

|

6000

|

2°

|

≤450

|

20-1000

|

5

|

15

|

22

|

6600×2400×2350

|

|

12×2500

|

12

|

2500

|

2°

|

≤450

|

20-600

|

9

|

18.5

|

8

|

3100×1850×2020

|

|

12×3200

|

12

|

3200

|

2°

|

≤450

|

20-600

|

9

|

18.5

|

9.4

|

3800×1820×1920

|

|

12×4000

|

12

|

4000

|

2°

|

≤450

|

20-600

|

8

|

18.5

|

11.8

|

4600×1950×2100

|

|

12×5000

|

12

|

5000

|

2°

|

≤450

|

20-750

|

6

|

22

|

21

|

5600×2250×2150

|

|

12×6000

|

12

|

6000

|

2°

|

≤450

|

20-750

|

5

|

22

|

26

|

6600×2400×2350

|

|

16×2500

|

16

|

2500

|

2°30′

|

≤450

|

20-600

|

9

|

22

|

9.2

|

3100×1950×2080

|

|

16×3200

|

16

|

3200

|

2°30′

|

≤450

|

20-600

|

8

|

22

|

10.6

|

3800×1950×2080

|

|

16×4000

|

16

|

4000

|

2°30′

|

≤450

|

20-600

|

8

|

22

|

15.3

|

4600×2300×2180

|

Product Overview

UG (finite element) analysis method was used to optimize the design by computer.

The fuselage adopts an integral steel plate welded structure, which has good strength, stiffness and

vibration resistance.

Internal stress relief is carried out by tempering.

The overall frame is rust removed by sanding and sprayed with anti-rust paint.

There is an auxiliary tool holder on the work table, which is convenient for the blade to be adjusted

slightly.

The work table is equipped with a feeding roller ball, which is light to operate.

The blade gap adjustment adopts a stepless adjustment mechanism to adapt to the shearing needs of

different plate thicknesses and materials.

Rectangular lower insert with four cutting edges for extended blade life

Adjusting the shearing stroke can not only improve the processing efficiency, but also realize the

segmented shearing function.

The number of shearing times is automatically counted, which reduces the inventory work of cumber

some locks.

The fuselage adopts an integral steel plate welded structure, which has good strength, stiffness and

vibration resistance.

Internal stress relief is carried out by tempering.

The overall frame is rust removed by sanding and sprayed with anti-rust paint.

There is an auxiliary tool holder on the work table, which is convenient for the blade to be adjusted

slightly.

The work table is equipped with a feeding roller ball, which is light to operate.

The blade gap adjustment adopts a stepless adjustment mechanism to adapt to the shearing needs of

different plate thicknesses and materials.

Rectangular lower insert with four cutting edges for extended blade life

Adjusting the shearing stroke can not only improve the processing efficiency, but also realize the

segmented shearing function.

The number of shearing times is automatically counted, which reduces the inventory work of cumber

some locks.

Hot Searches