- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

BRD Machine

-

Voltage:

-

380V

-

Power:

-

200KW

-

Dimension(L*W*H):

-

custom-made

-

Weight:

-

1000 kg

-

Features:

-

high-performance

-

Raw materials:

-

Concrete

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Product name:

-

Fiber Cement Board Production Line

-

Name:

-

Wallboard Machine

-

Usage:

-

House Roofing

-

Advantages:

-

Fireproof Waterproof

-

After Warranty Service:

-

Field Maintenance

-

Usage of board:

-

Prefabricated Wall Panel

-

Function:

-

Wall Panel Molding Equipment

-

Use:

-

Insulation Wall

Quick Details

-

Application:

-

Fiber Cement Board Producing Machines

-

Production Capacity:

-

2000pieces/8 hours

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

BRD Machine

-

Voltage:

-

380V

-

Power:

-

200KW

-

Dimension(L*W*H):

-

custom-made

-

Weight:

-

1000 kg

-

Features:

-

high-performance

-

Raw materials:

-

Concrete

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Product name:

-

Fiber Cement Board Production Line

-

Name:

-

Wallboard Machine

-

Usage:

-

House Roofing

-

Advantages:

-

Fireproof Waterproof

-

After Warranty Service:

-

Field Maintenance

-

Usage of board:

-

Prefabricated Wall Panel

-

Function:

-

Wall Panel Molding Equipment

-

Use:

-

Insulation Wall

PORDUCT DETAILS

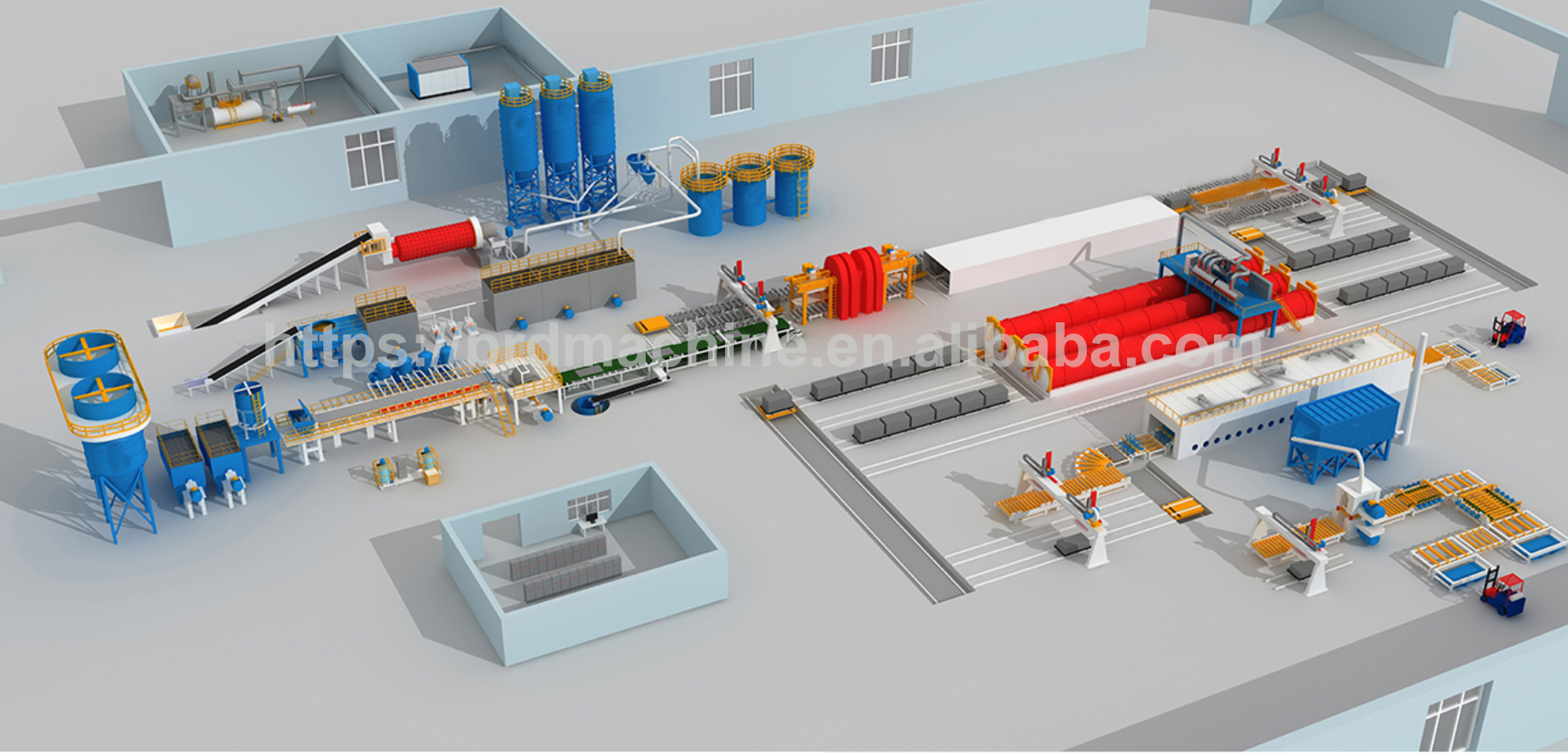

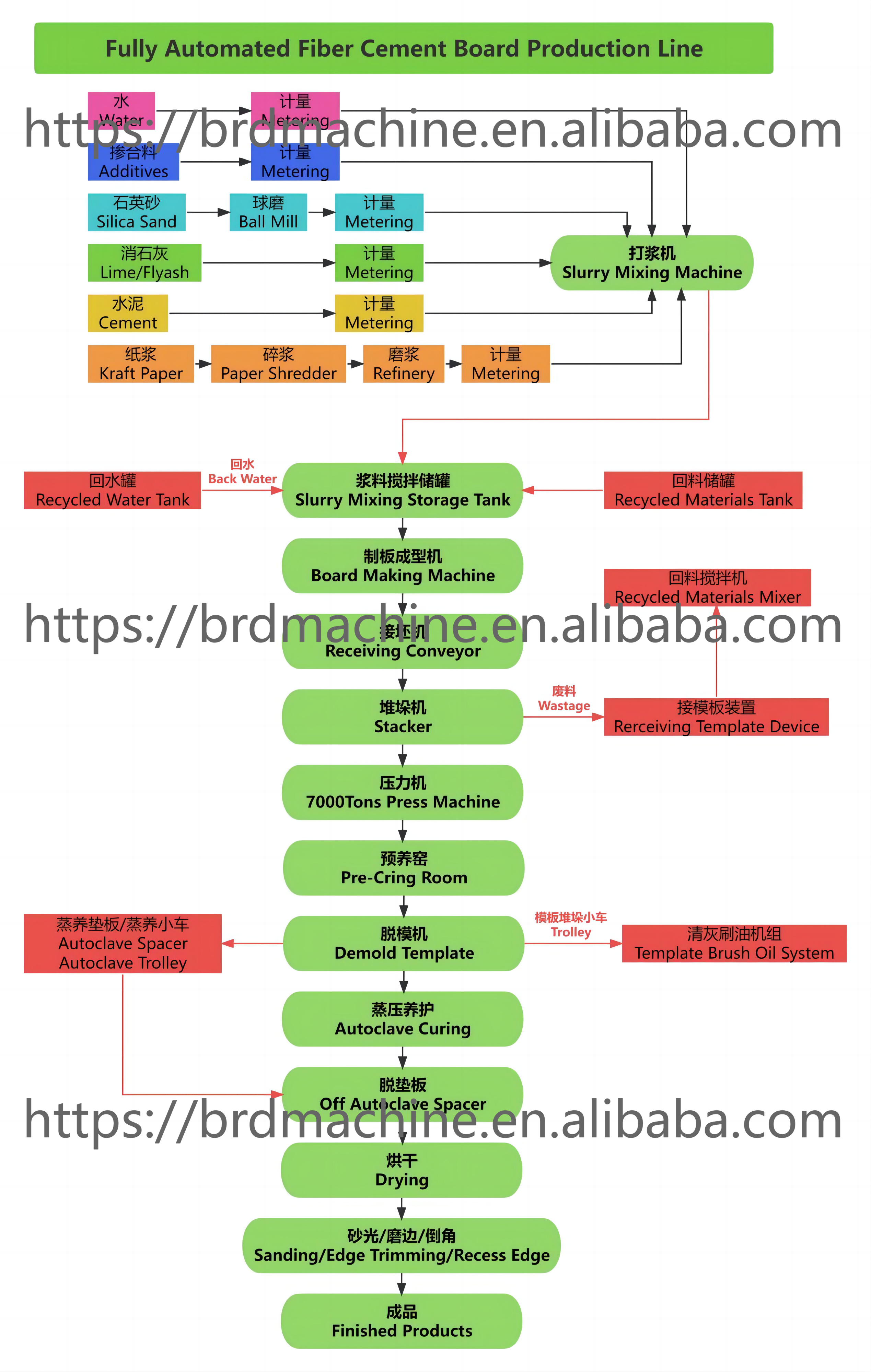

Automated Fiber Cement Board Production Line

Section introduction

1.Pulp system

The company selects high-consistency, medium-consistency, and low consistency paper shredders according to the user's main pulp raw material types; adopts metering belt feeding, and configures water metering methods according to whether the shredding method is continuous or intermittent. Water measurement methods are divided into: flow meter + automatic adjustment valve, measuring tank + weighing method of weighing sensor.

2.

Feed system

This system is mainly for batching pulping according to the technical formula requirements of product raw materials. Different materials are divided into one or more pulping processes, and the required supporting equipment will have different changes.

3.Flowing Board Host

Flow slurry method is a general method for forming fiber cement board and calcium silicate board. The equipment structure is different from the copying method, easy to control operation and maintenance, less slurry loss, and better product performance. This is suitable for the production of various quality boards, especially low-density lightweight boards.

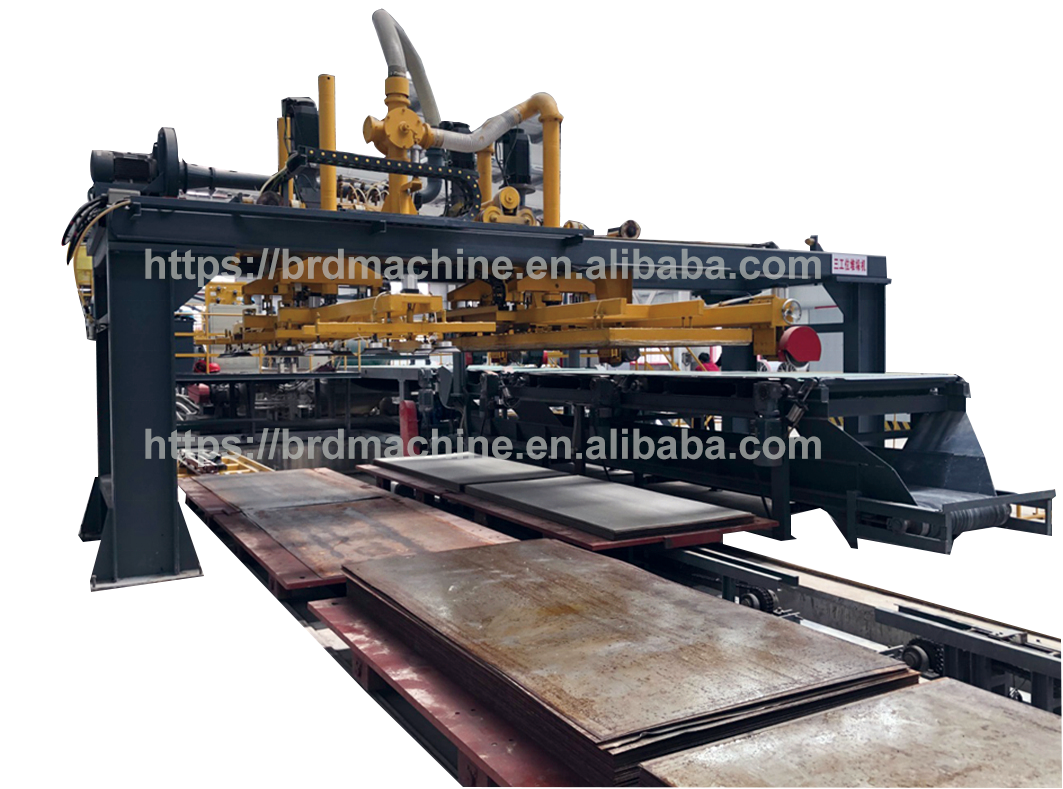

4.High Pressure Water Jet Cutting

1.For the first time, a long-stroke high-performance supercharger is used to improve the service life of parts.

2.Dual oil circuit control design realizes quick switching of booster assembly and improves equipment stability.

3.It can meet the cutting of plates of different thicknesses and flexibly adapt to production needs.

5.Stacking

The short stroke stacker is a traditional suction cup short stroke cylinder lifting and lifting platform. Its biggest advantage is less investment, simple maintenance and higher cost performance.The suction cup is raised and lowered by a long-stroke servo motor, and the trolley is servo-controlled, with a coherent action, which is easy to connect with the subsequent automation equipment. There is no lifting platform to reduce oil pollution. However, the investment is high, the technical level of maintenance personnel is required to be high, and the daily mechanical and electrical maintenance requirements are high.

6.

Demould

Fiber cement board stripping machine is a modern construction equipment, widely used in all kinds of construction projects. Its main function is to quickly and efficiently remove the fiber cement board from the mold, thereby improving production efficiency. The emergence of fiber cement board stripper has greatly improved the construction speed and quality of the construction industry, and provided strong support for the realization of construction industrialization.

7.Autoclave

The high-temperature and high-pressure professional equipment selected according to the characteristics of the cement fiber board and calcium silicate board generally adopts the upper-opening door structure.

8.Drying

Fiber cement board drying kiln is an advanced industrial equipment, widely used in construction, decoration, furniture and other industries. Because of its excellent performance and environmental protection characteristics, fiber cement board has gradually become the preferred material for modern architectural decoration.

9.Edge grinding and chamfering

The maximum cutting thickness of the edger can cut 3-35mm plates, and the horizontal grinding can be equipped with an electric width adjustment device to reduce the time when changing sizes.

Production sample introduction

Calcium silicate board

Fibre cement board

Fibre cement tile

Our company is mainly engaged in the production of heavy building materials machinery and equipment, integrating scientific research, production, sales and service. Committed to building materials machinery research and innovation. Our company mainly produces dozens or hundreds of models of building materials production line, fiber cement board production line, calcium silicate board production line, fiber cement tile production line, calcium silicate insulation board production line, aerated brick production line, wood crushing production line, incense production line, sand production line, grinding production line, drying production line, calcining production line, etc. Including crushing equipment, screening equipment, sand making equipment, grinding equipment, drying equipment, etc. From casting molding, mechanical processing, physical and chemical treatment to assembly and assembly machines, quality inspection engineers track and test the whole process, and through a number of quality system certifications, to ensure that users are provided with high-quality and reliable equipment.

Over the years, the company has always adhered to the integrity of management, customer service as the fundamental principle. With scientific management methods, continuous improvement of manufacturing processes, innovative manufacturing concepts, rapidly grow into a new star in China's building materials machinery industry. Product sales network throughout the country, some products are exported to Russia, Turkey, Morocco, Egypt, Bolivia, Chile, Malaysia, India, Nepal, Brazil, Kazakhstan, Kyrgyzstan, Tajikistan, Pakistan, Turkmenistan, Dubai, the Middle East, Africa and other countries and regions.

We are full of energy and confidence. Based on the thick soil of the Central Plains, we look to the whole world. We regard quality as life, regard users as God, and always adhere to the quality policy of each process, each product, and each user. We are dedicated to customer service.

All the staff of our company warmly welcome new and old customers to the factory to discuss cooperation, visit guidance!

|

Whatsapp:+86 15537977969Ethan

|

|

|

|

|

||||

Hot Searches