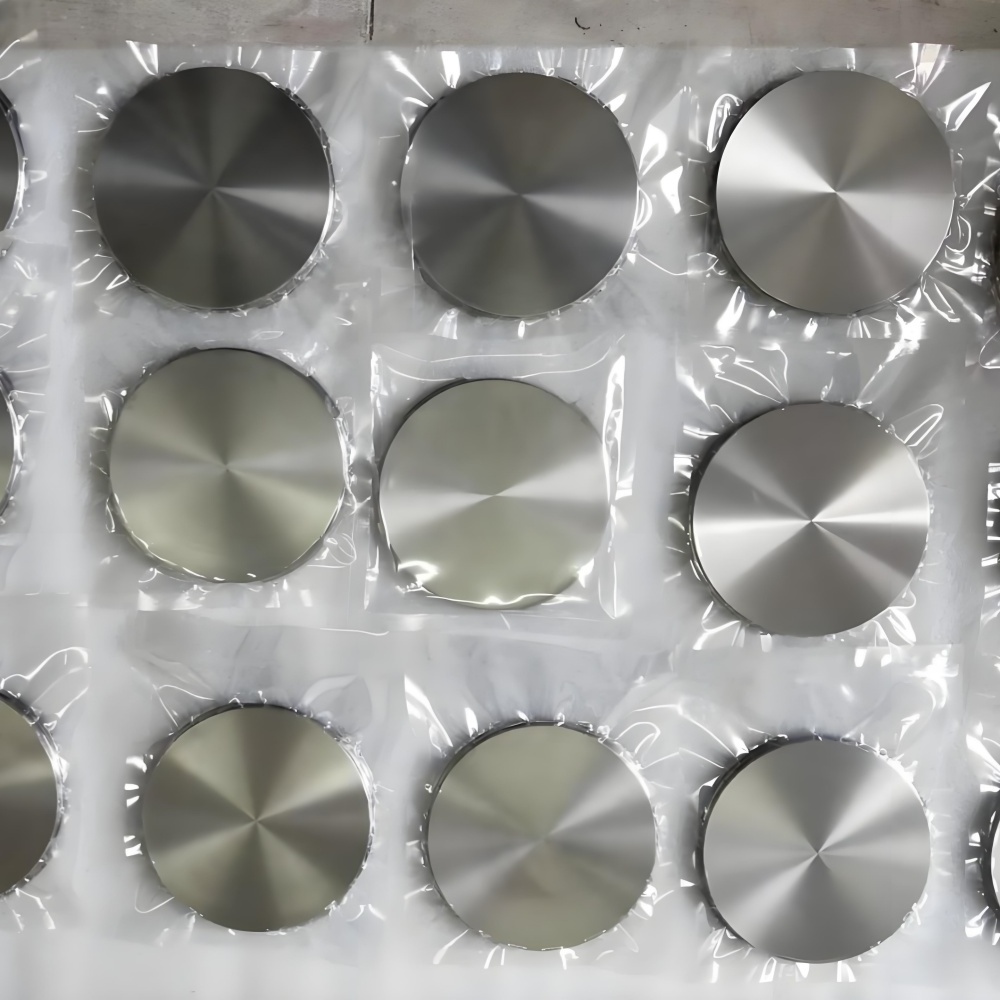

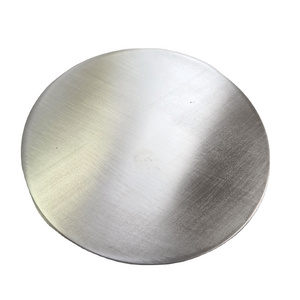

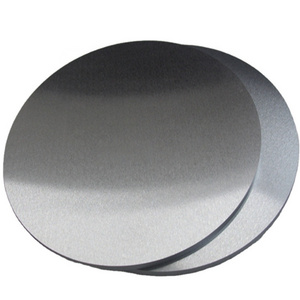

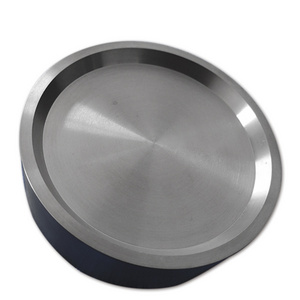

(1) Smooth surface without pore,scratch and other imperfection

(2) Grinding or lathing edge, no cutting marks

(3) Unbeatable level of material purity

(4) High ductility

(5) Homogeneous micro structure

(6) Laser marking for your special Item with name, brand, purity size and so on

(7)Every pcs of sputtering targets from the powder materials item&number, mixing workers,outgas and HIP time,machining person and packing details are all made ourselves.

All of those step can promise you once a new sputtering target or method is created ,it could be copied and kept to support a stable quality products.

(3) Unbeatable level of material purity

(4) High ductility

(5) Homogeneous micro structure

(6) Laser marking for your special Item with name, brand, purity size and so on

(7)Every pcs of sputtering targets from the powder materials item&number, mixing workers,outgas and HIP time,machining person and packing details are all made ourselves.

All of those step can promise you once a new sputtering target or method is created ,it could be copied and kept to support a stable quality products.