- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≤±5mm, ≤±5mm

-

Voltage:

-

380V, 380V 50HZ 3PH or customized

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

3800x1380x1850mm

-

Weight:

-

2400 KG

-

Product name:

-

Automatic Bottle Washing Filling Capping Machine

-

Capacity:

-

6000-9000BPH

-

Bottle type:

-

Pop-top can

-

Cap type:

-

200-900ml

-

Air pressure:

-

0.6

-

Certification:

-

ISO, CE

-

Function:

-

Automatic Filling Capping Machine

-

Usage:

-

Beverage Filling Packaging

-

Suitable for:

-

Water Filling Line

-

Advantage:

-

Automatic Working

Quick Details

-

Machinery Capacity:

-

6000-9000BPH, 15000-18000BPH

-

Packaging Material:

-

Plastic, Glass, Other

-

Filling Material:

-

Beer, Other, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

≤±5mm, ≤±5mm

-

Voltage:

-

380V, 380V 50HZ 3PH or customized

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

3800x1380x1850mm

-

Weight:

-

2400 KG

-

Product name:

-

Automatic Bottle Washing Filling Capping Machine

-

Capacity:

-

6000-9000BPH

-

Bottle type:

-

Pop-top can

-

Cap type:

-

200-900ml

-

Air pressure:

-

0.6

-

Certification:

-

ISO, CE

-

Function:

-

Automatic Filling Capping Machine

-

Usage:

-

Beverage Filling Packaging

-

Suitable for:

-

Water Filling Line

-

Advantage:

-

Automatic Working

Product Description

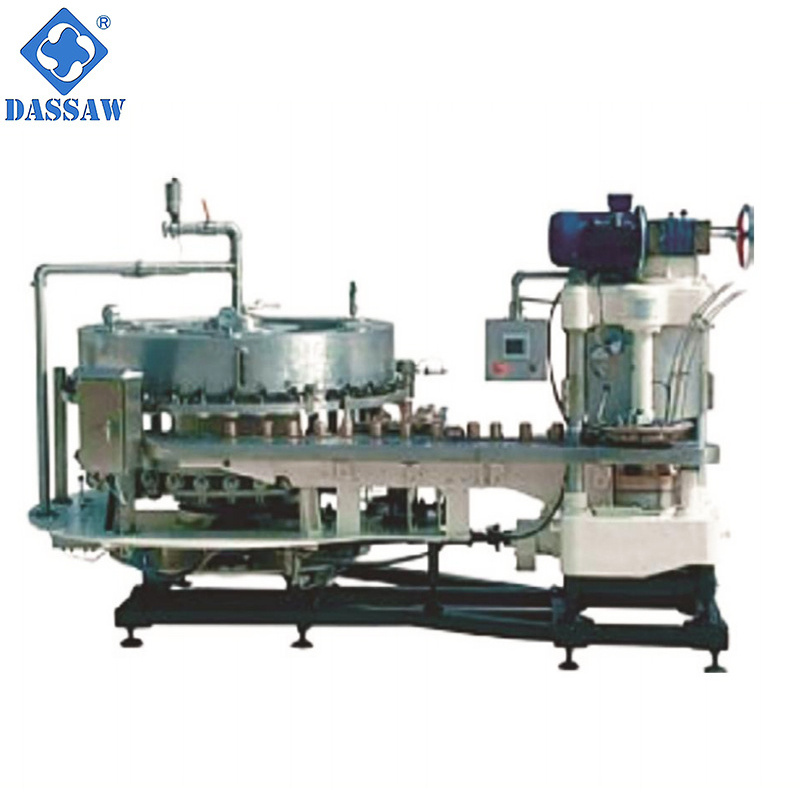

YF18-4D/YF32-6D pop can filler and capper(Carbonated/ Non-carbonated)

The machine is specially used for filling effervescent beverage(such as carbonated beverages, beer, milk, juice etc.) into two-piece aluminum pop cans. The advanced PLC and frequency conversion technology can ensure the whole production line is running stably at high speed,with high production efficiency, convenient operation and maintenance, and beautiful and decent appearace.

Product Paramenters

|

Model

|

YF18-4D

|

YF32-6D

|

|

Capacity(BPH)

|

6000-9000

|

15000-18000

|

|

Filling&Capping heads

|

18-4

|

36-2

|

|

Can Type

|

200-900ml

|

200-900ml

|

|

Air Pressure

|

0.6

|

0.6

|

|

Weight (KG)

|

2400

|

3500

|

|

Dimension(mm)

|

3800x1380x1850

|

4200x1710x1800

|

Details Images

Features:

1)The exterior surfaces and all parts directly contacting liquid are made of high-quality stainless steel, which guarantees

beautiful appearance and conforms to the requirement of food hygiene.

beautiful appearance and conforms to the requirement of food hygiene.

2)Passive drive guarantees synchronous filling and capping.

3)The automatic spring valve serves as the filling valve. The mechanism floating barrel principle is adopted to control liquid level.It is featured by reliable running, convenient operation and easy maintenance.

4)The power input interface of machine can connect with various cappers. It can form the filler and capper unit through

combination with the imported 6-head capper, and the production capacity can be adjusted through frequency conversion of the capper.

3)The automatic spring valve serves as the filling valve. The mechanism floating barrel principle is adopted to control liquid level.It is featured by reliable running, convenient operation and easy maintenance.

4)The power input interface of machine can connect with various cappers. It can form the filler and capper unit through

combination with the imported 6-head capper, and the production capacity can be adjusted through frequency conversion of the capper.

Related Products

Soda Sugar Mixer Machine

Certifications

Hot Searches