- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Office Building

-

Design Style:

-

Modern

-

Place of Origin:

-

Gyeonggi-do, South Korea

-

Brand Name:

-

Nano Heat

-

Model Number:

-

Heating Rail

-

Using Voltage:

-

AC220V~230V

-

Usage:

-

Floor Heating Element / Agricultural Facilities

-

Width:

-

815mm

-

Heating Element Interval:

-

10cm

-

Electricity Consumption:

-

130~110watt/meter (from 10℃ ~ 65℃)

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Online technical support, Return and Replacement, Other

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects

-

Application:

-

Office Building

-

Design Style:

-

Modern

-

Place of Origin:

-

Gyeonggi-do, South Korea

-

Brand Name:

-

Nano Heat

-

Model Number:

-

Heating Rail

-

Using Voltage:

-

AC220V~230V

-

Usage:

-

Floor Heating Element / Agricultural Facilities

-

Width:

-

815mm

-

Heating Element Interval:

-

10cm

-

Electricity Consumption:

-

130~110watt/meter (from 10℃ ~ 65℃)

General Information

|

Product Name |

Heating Rail (Cable Mat) |

|

HS Code |

8545.90.2000 |

|

Order Unit |

1 Box (500 pieces / 50meters / 40.75 Square Meters) |

|

Minimum Order Quantity |

20 Boxes (1,000 meters) |

|

Daily Producing Quantity |

200,000 Meters per Month(4,000 Boxes) |

|

Certifications |

CE, RoHS, TUV, IP-68, EAC, ISO9001 |

|

Warranty Period |

10 Years after Purchasing |

|

Payment Terms |

T/T, Western Union, Pay Pal, Irrevocable L/C |

|

Basic Price Terms |

F.O.B. Busan Port / Incheon Airport, Korea |

|

Shipment Period |

Shipment will be completed within a week after balance payment |

|

Departing Port |

Busan Port or Incheon Port (Ocean Freight )

|

The Introduction of Manufacturer

Nanotech is a company that has been producing floor heating systems using eco-friendly, high-efficiency carbon heaters since 2006.

Nanotech developed 'Nano Heat', a self-regulating (PTC) heating cable mat with a parallel rail structure, in 2011 based on excellent technology accumulated through 7 years of continuous research.

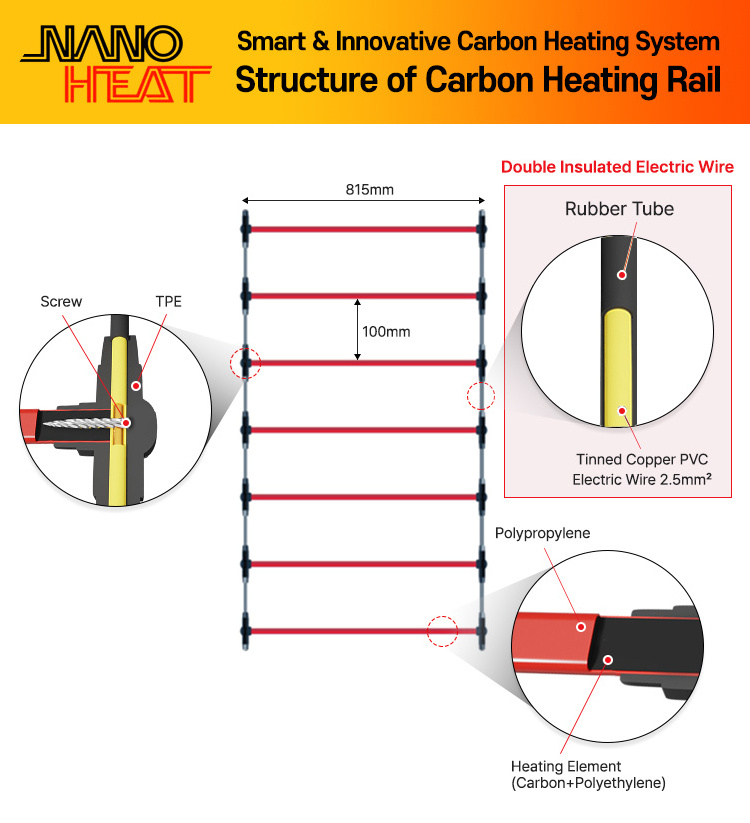

Nano Heat arranges PTC carbon heater rods in a parallel rail structure for easy construction and achieves excellent heating efficiency. In addition, the parallel rail structure solves the problem of maintaining stable power consumption, which was a problem with existing PTC heating cables.

Nano Heat has been registered as Korea's excellent procurement product and installed in various children's facilities, commercial facilities, lodging facilities, and nursing facilities.

Nano Heat have received certifications such as CE, RoHS, EAC, ISO 9001, and K mark. In addition, it has been exported to the United States, Canada, Germany, Poland, Sweden, Russia, China, Slovakia, Uzbekistan, Kazakhstan, and Mongolia, and has grown into an eco-friendly heating material attracting attention in the global market.

Nano Heat certainly contributes to give more economical, safer, healthier and better heating environment to consumers.

What is PTC(Positive Temperature Coefficient)?

PTC(Positive Temperature Coefficient) characteristic was discovered by American doctor Herman in 1950’s. It is the phenomenon even though the ambient temperature increases, but the calorific power decreases by certain proportion mechanically.

PTC heating rail does not use any metallic heating elements like Nickel-Chrome line, it is made of nano-compound which is made of mixture of carbon - conductive materials and polyethylene resins have characteristic that is easily inflated and shrunken by heat.

So, when the temperature increases in one area of heating rail, the polyethylene resins inflate. It causes increase of electric resistance of heating rail, so electricity consumption decreases.

In addition to that, it is very effective to prevent partial overheating. In case of heating rail, it can’t generate over 65 Celsius degree.

Heating rail generates more heat when the temperature is low, whereas, it produces less heat in hot temperature. Therefore, it is not only safe and but also consumes less electricity (energy saving effect).

The temperatures of a room are different following its circumstance due to differences of lightening, humidity and insulation. But, the PTC effect of heating rail means that every section of heating rail acts as its own thermostat. So every part of the floor is always maintained at the even temperature with the minimum use of energy. Such an intelligent function heating rail makes heating rail the most efficient electrical heating system.

Specifications of Heating Rail

|

Product Name |

PTC (Self Controlled) Heating Rail (Cable) Mat |

|

Using Voltage |

AC 220~230 Voltage (50~60Hz) |

|

Usage |

Floor Heating / Agricultural Facilities |

|

Dimensions |

815mm Width * 100mm Interval * 5mm Thickness |

|

Heater Rod Quantity |

500 Pieces / Box |

|

Power Consumption / Heater Rod |

13~11 Watt / Rod (10℃ ~ 65℃) |

|

Power Consumption per Meter |

130watt ~110watt per Meter(10 Heater Rods) |

|

Maximum Maintaining Temperature |

65℃ |

|

PTC efficiency |

15% |

|

Materials |

Outer Jacket : Polypropylene Heating Stick : Compound of Carbon & Polyethylene |

|

Packing Method |

Carton Box (500 pieces / 50meters / 41.5 square meters) |

|

Carton Box Size |

90m X 47 X 38cm |

|

Carton Box Gross Weight |

23 Kgs |

Specifications of EP Insulation Board

|

Product Name |

EP Board |

|

HS Code |

3921.19.9090 |

|

Order Unit |

1 Box (15 Sheets, 6.375 square meter) |

|

Usage |

Floor Insulation for Heating Rail & Heating Cable |

|

Dimensions |

850mm Width * 500mm Length * 18mm Thickness |

|

Materials |

Compressed XPS Board + Embossed Aluminum Sheet |

|

Minimum Order Quantity |

40 Boxes (255 Square Meters) |

|

Carton Box Size |

87 X 52 X 33cm |

|

Carton Box Gross Weight |

6Kgs |

Feature of EP Insulation Board

EP board is an insulation material developed to enable easy installation by omitting wet mortar construction of heating rails and heating cables.

EP board is composed of compressed XPS board and a heat-reflective aluminum layer which improves heating effects, energy saving effects, insulation and is a building material for alleviating noise between floors.

Superiority of Heating Rail Heating System

Maintenance Cost-Saving Heating System

Cost efficient than other electric heating products due to PTC characteristics of product

Simple structure and design without product failures

Semi-permanent product life span & waterproof product structure

Overheating prevention (PTC characteristics prevent heat up over 65 Celsius degree)

Capable of having even heating effect about heating space

Easy-to-install and economical heating system

Capable of reducing installation expenses due to an easy-to-construction/installation process meaning reducing construction times

Parallel structure of heating elements is able to realize faster heating effect

Capable of heating partially and saving unnecessary heating expenses (Possible to adopt a central control system)

Capable of having more capacious living space by not needing a separate boiler space

Eco-friendly and Healthy Heating System

Heating element is made of compound of carbon and polyethylene, emitting less electronic waves

Far-infrared ray and anion suppresses Sick House Syndrome, odor, and growth of germs.

It does not use flames, so it generates less noise, dust, and carbon monoxide

It is perfect for areas with children, senior citizens and patients

Subsidiary Materials for Heating Rail Installation

Entire Heating Rail Installation Process

Cover the base floor of the area where heating will be installed with insulation pad.

The heating rail is cut to fit the construction site.

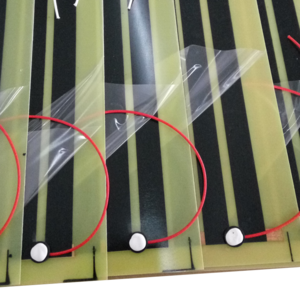

Connect the heating rail and double insulated wire using a non-insulated butt splice connector and heat shrink tube to form a heating circuit.

(The maximum length of heating rails that can be installed in a row is 15 meters.)

Make holes in the insulation pad here and there to ensure good bonding between the floor and mortar.

Cover heating rail circuit with heat radiation net to improve heating effect and prevent cracks in mortar.

Cover the heating rail circuit with mortar and install the finishing material.

Connection of heating rail and double insulated electric wire

Remove 1.5cm of the covering from the heating rail and double-insulated electric wire.

Cut 5cm of Heat Shrink Tubing and push it into the double insulated electric wire.

Push the stripped heating rail and double insulated wire into the non-insulated butt splice connector.

Press the non-insulated butt splice connector with a wire crimper to secure the wires.

Move the heat shrink tubing so that the non-insulated butt splice connector are completely covered.

Heat the heat shrink tubing using a gas torch gun or a heat gun.

Make sure the heat shrink tubing is completely adhered to the sheath of the wire.

Using insulating tape, wrap it around the wire connection area wider than the shrink tubing.

Electric Insulation Treatment of Heating Rail Ending Part

Cut the heat shrink tubing so that all the cut wires of the heating rail are covered and at least 3cm remains.

Slide the heat shrink tubing onto the cut wire on the heating rail.

Heat the heat shrink tubing using a gas torch gun or a heat gun.

Press and flatten the heat shrink tubing with a compressor so that it can stick together.

Make sure the heat shrink tubing is completely adhered to the sheath of the wire.

Cut the middle part of the flat, compressed shrink tubing with a knife or scissors.

Using electrical insulating tape, wrap it wider than the shrink tubing.

Strong to Sunlight Exposure “Nano Heat”

The heater rod of the Nano Heat heating rail is made of thick polypropylene and the wire part is covered with rubber, so it does not harden or deform even when exposed to sunlight for a long period of time.