- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Jingchi tools

-

Product Name:

-

KC-CX rotary broach tool

-

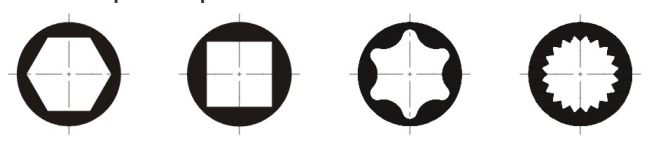

Broach shape:

-

Hex,square,spline

-

Shank Size:

-

Mohs taper shank/Straight shank

-

Hardness:

-

Suit less than HRC30

-

Application:

-

Machining

-

Usage:

-

Finish Machining

-

Certificate:

-

ISO9001

-

OEM:

-

Accept

-

MOQ:

-

1

-

Packing:

-

Carton

Quick Details

-

Material:

-

HIGH SPEED STEEL

-

Type:

-

Face Mill

-

Finish:

-

Bright(Uncoated)

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Jingchi tools

-

Product Name:

-

KC-CX rotary broach tool

-

Broach shape:

-

Hex,square,spline

-

Shank Size:

-

Mohs taper shank/Straight shank

-

Hardness:

-

Suit less than HRC30

-

Application:

-

Machining

-

Usage:

-

Finish Machining

-

Certificate:

-

ISO9001

-

OEM:

-

Accept

-

MOQ:

-

1

-

Packing:

-

Carton

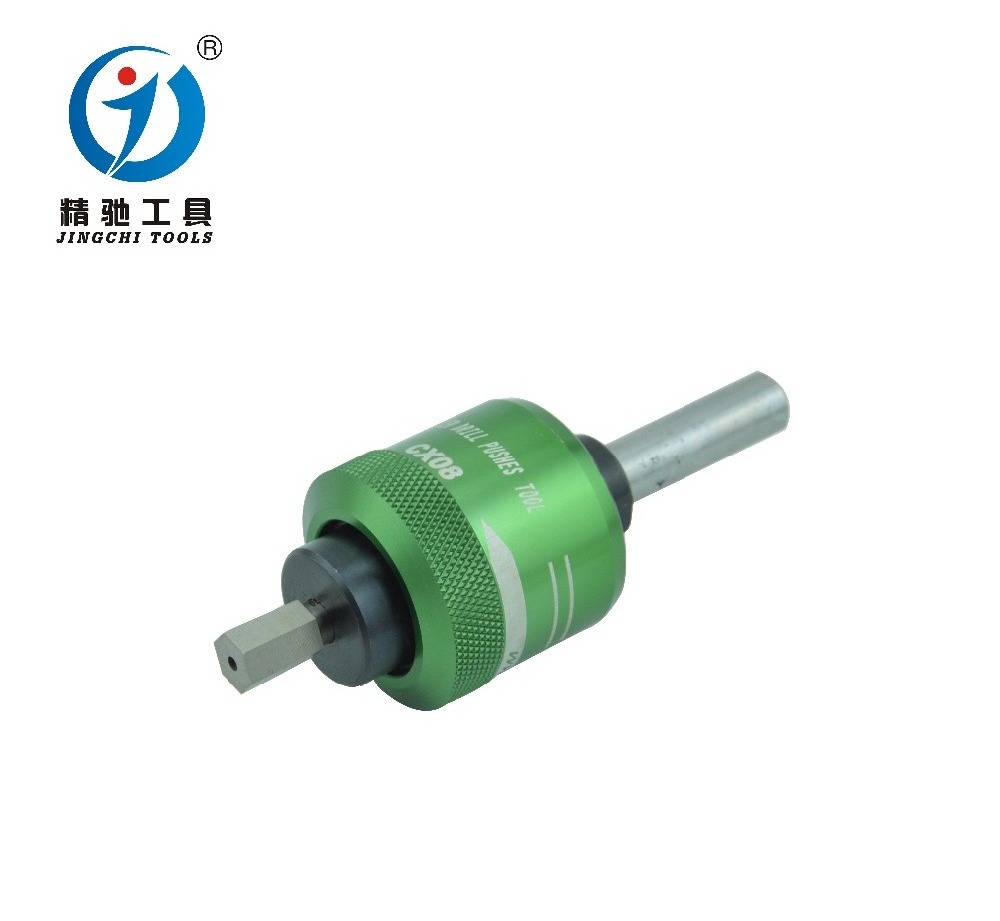

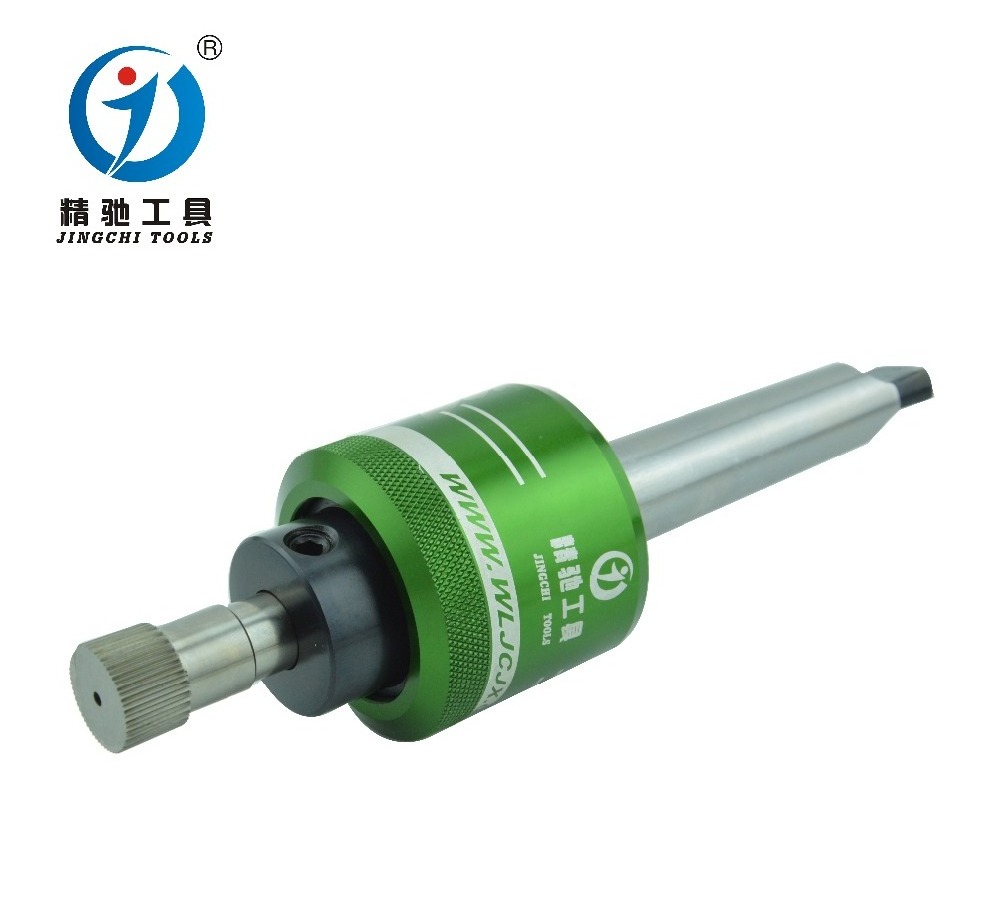

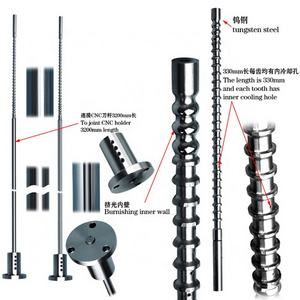

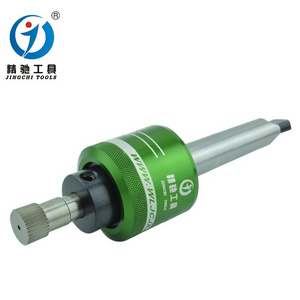

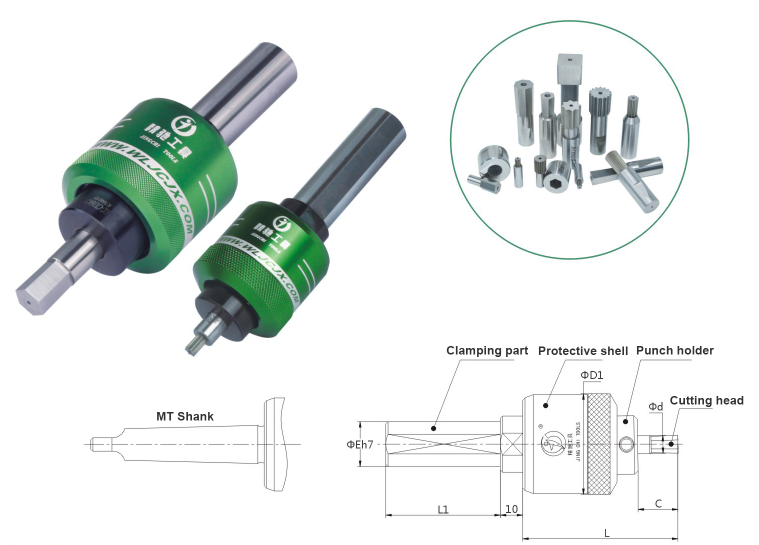

KC-CX spline broaching on cnc lathe splined hole internal rotary broach tool holder

KC-CX SERIES ROTARY BROACH TOOL

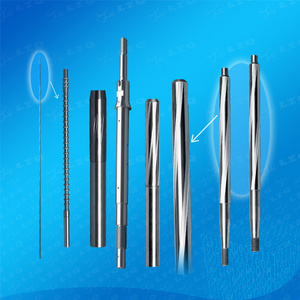

Rotary broach tool works by rotating the cutting force.It is most suitable for geneal machines,CNC automatic lathe,drilling machine.It can be used to make blind holes,through holes or regular/irregular polygons.Apart from standard hexagon and square holes,special shapes such as star shape and spline can also be cstomized.

1.Product performace and features

1.No need to malke Punch head or electrode,reduce the cost,quaity is good, improve efficiency,has strong generality.

2.One step of lathe work,reduce process and processing time.Use this tool can make square hole and hexagonal hole etc.Only need 30s to process a hexagonal hole which is 10mm width and 15mm depth.

3.Suitable to process parts which hardness less than HRC30.

2.Method of use

1.Use rotary broach tool,you can rotate the tool or the parts.It means you can use on lathe,milling machine,drill machine and CNC machine.In order to make sure the working accuracy,you must calibrat center.

2.Working speed:800-2000R.P.M,Feed:0.02-0.1mm/rev,Increase 2-3times for copper/aluminum parts

KC-CX INTERNAL ROTARY BROACH TOOL

Product Data

|

Model |

Size |

Broach Head |

||||

|

Shank |

D1 |

d |

L |

C |

||

|

KC-CX08AM2 |

MT2 |

45 |

8 |

70 |

18 |

KC-CT08A-*** |

|

KC-CX08AM3 |

MT3 |

|||||

|

KC-CX08AM4 |

MT4 |

|||||

|

KC-CX08A12 |

Φ12×40 |

|||||

|

KC-CX08A16 |

Φ16×50 |

|||||

|

KC-CX08A20 |

Φ20×60 |

|||||

|

KC-CX08A25 |

Φ25×60 |

|||||

|

KC-CX08A32 |

Φ32×80 |

|||||

|

KC-CX16(A/B)M2 |

MT2 |

62 |

16 |

112/

|

A=40

|

KC-CT16(A/B)-*** |

|

KC-CX16(A/B)M3 |

MT3 |

|||||

|

KC-CX16(A/B)M4 |

MT4 |

|||||

|

KC-CX16(A/B)A16 |

Φ16×50 |

|||||

|

KC-CX16(A/B)A20 |

Φ20×60 |

|||||

|

KC-CX16(A/B)A25 |

Φ25×60 |

|||||

|

KC-CX16(A/B)A32 |

Φ32×80 |

|||||

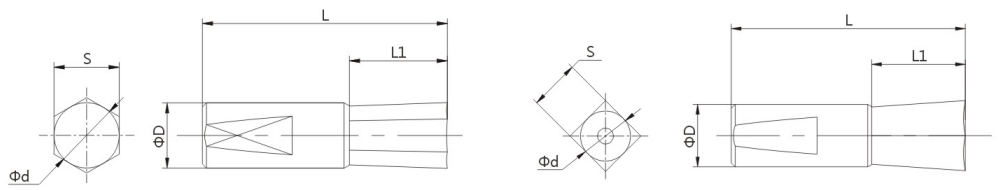

Parameters of internal broach cutters