- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

JXSC

-

Dimension(L*W*H):

-

depends

-

Weight:

-

500 KG

-

Product name:

-

Rubber Ball Mill Liner

-

Keywords:

-

Rubber Mill Liner

-

Color:

-

Customer Requirement

-

Quality:

-

High Level

-

Factory Visit:

-

Welcomed Warmly

-

Price:

-

Negotiable

-

Usage:

-

Mining Concentration

-

After sale service:

-

Techniacal Support

-

Advantages:

-

High Efficiency Low Energy

-

Model:

-

DEPENDS

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Capacity(t/h):

-

depends

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

JXSC

-

Dimension(L*W*H):

-

depends

-

Weight:

-

500 KG

-

Product name:

-

Rubber Ball Mill Liner

-

Keywords:

-

Rubber Mill Liner

-

Color:

-

Customer Requirement

-

Quality:

-

High Level

-

Factory Visit:

-

Welcomed Warmly

-

Price:

-

Negotiable

-

Usage:

-

Mining Concentration

-

After sale service:

-

Techniacal Support

-

Advantages:

-

High Efficiency Low Energy

-

Model:

-

DEPENDS

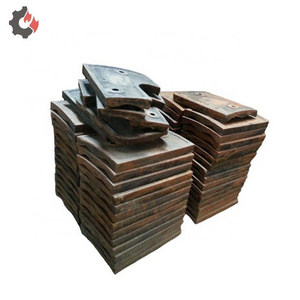

Products Description

Rubber liners

We provides wear-resistant mill liner for various types of ball mills, such as groove lining boards, trapezoidal lining boards,

ring groove lining boards, corrugated lining boards, silo boards, grate plates and other ball mill lining boards, and can also

manufacture products of different materials according to the drawings provided by customers. Mill liner is generally divided into five categories according to its use parts: cylinder lining plate, grinding head lining plate, silo plate, grate plate, manhole lining plate and special lining plate. Among them, the shape of ball mill barrel lining board is not simple plate, Angle spiral, round corner square lining board, groove lining board, trapezoidal lining board, its forms and shapes are numerous.

ring groove lining boards, corrugated lining boards, silo boards, grate plates and other ball mill lining boards, and can also

manufacture products of different materials according to the drawings provided by customers. Mill liner is generally divided into five categories according to its use parts: cylinder lining plate, grinding head lining plate, silo plate, grate plate, manhole lining plate and special lining plate. Among them, the shape of ball mill barrel lining board is not simple plate, Angle spiral, round corner square lining board, groove lining board, trapezoidal lining board, its forms and shapes are numerous.

Rubber lining can also be used in trommel scrubber.Suitable liner can be customized according to your machine model and requirements.

Material: Mn13, Mn13Cr2, Chromium alloy steel, rare earth wear-resisting steel

Process: lost mold

Applicable machinery: ball mill, vertical mill, mill, mill, crusher

Performance advantages:

1.Using modified high manganese steel and super high manganese steel, has enough impact toughness.

2. Optimize the heat treatment process, high hardness, strong wear resistance, long service life.

3. Large crushing ratio and high crushing efficiency.

4. Cost-effective, easy to disassemble.

Process: lost mold

Applicable machinery: ball mill, vertical mill, mill, mill, crusher

Performance advantages:

1.Using modified high manganese steel and super high manganese steel, has enough impact toughness.

2. Optimize the heat treatment process, high hardness, strong wear resistance, long service life.

3. Large crushing ratio and high crushing efficiency.

4. Cost-effective, easy to disassemble.

High manganese ball mill liner is used to protect the inner wall of crushing equipment, so that it is protected from the material or other objects into the inner cavity of the direct impact and friction, and can use different forms of high manganese ball mill liner to adjust the movement of the material, in order to strengthen the crushing effect of equipment on the material, improve the efficiency of equipment, increase output. In the operation of the equipment, the ball mill liner needs to withstand the impact, impact and friction of large materials, and wear is relatively fast, so the ball mill liner is required to have certain wear resistance and high impact resistance. While high manganese steel is easy to produce work hardening under high impact force, especially in some high impact conditions, the surface hardening thickness of high manganese steel can reach 10-20mm, and the hardening layer of high hardness can resist impact abrasive wear. Under strong impact conditions, the anti-wear performance is outstanding. And the high manganese ball mill liner produced by JXSC is treated with water toughness, which further enhances its wear resistance and impact resistance.

The rubber liners is used on the ball mill▼

The rubber liners is used on the ball mill▼

Specification

We can customize various sizes of ball mill liners, welcome to consult!

|

Product Name

|

ball mill liners

|

|

Mould process

|

casting or forging

|

|

certification

|

IOS

|

|

Inspection

|

Raw material inspection, UT,physical property test,dimension inspection

|

|

advantage

|

high quality low cost

|

|

Processing

|

casting, rough machining, QT, finish machining

|

|

color

|

customer's request

|

|

price

|

Can discuss

|

Packing and Delivery

●Ways Of Packing

1.Small parts packed in the wooden cases.

2.Big parts packed by plastic membrane.

3.The whole big machine is loaded in the container.

● Shiping by sea/air freight

or any way the customer requires.

Hot Searches