- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Working temperature:

-

0~1100℃

-

Temperature control accuracy:

-

±1℃

-

Furnace tube material:

-

Ultra-high temperature alloy

-

Sealing method:

-

Pressure resistant CF flange

-

Flange interface:

-

6.25

-

Overvoltage protection:

-

Safety deflation valve

-

Pressure regulation:

-

Manual electric free switching

-

Keywords:

-

High temperature and high pressure tube furnace

Quick Details

-

Warranty:

-

3 years

-

Brand Name:

-

CYKY

-

Model Number:

-

CY-HS1200-85I-T

-

Place of Origin:

-

Henan, China

-

Working temperature:

-

0~1100℃

-

Temperature control accuracy:

-

±1℃

-

Furnace tube material:

-

Ultra-high temperature alloy

-

Sealing method:

-

Pressure resistant CF flange

-

Flange interface:

-

6.25

-

Overvoltage protection:

-

Safety deflation valve

-

Pressure regulation:

-

Manual electric free switching

-

Keywords:

-

High temperature and high pressure tube furnace

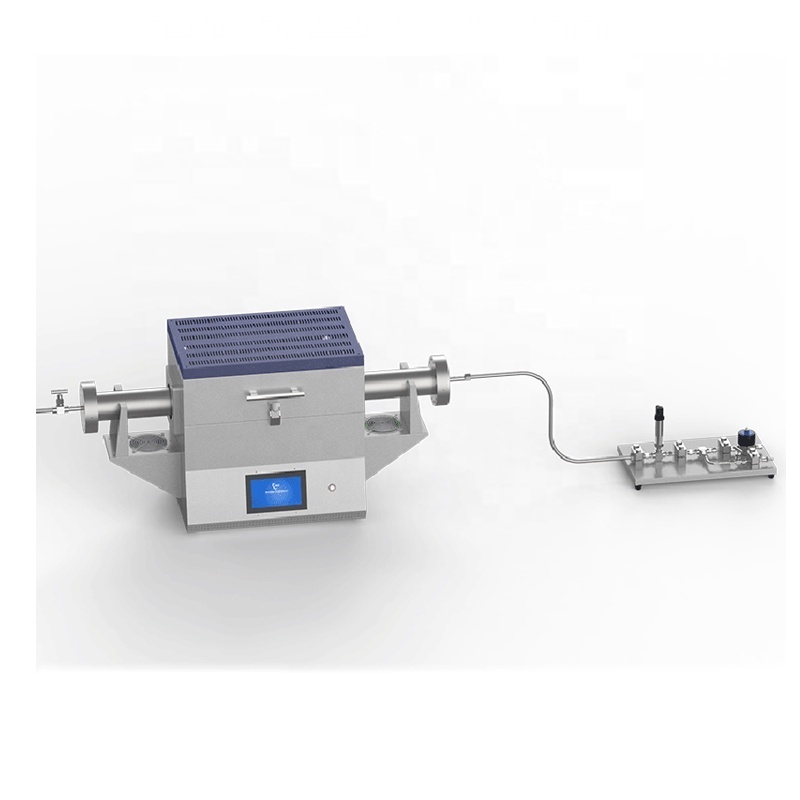

High temperature and high pressure tube furnace CY-HS1200-85I-T

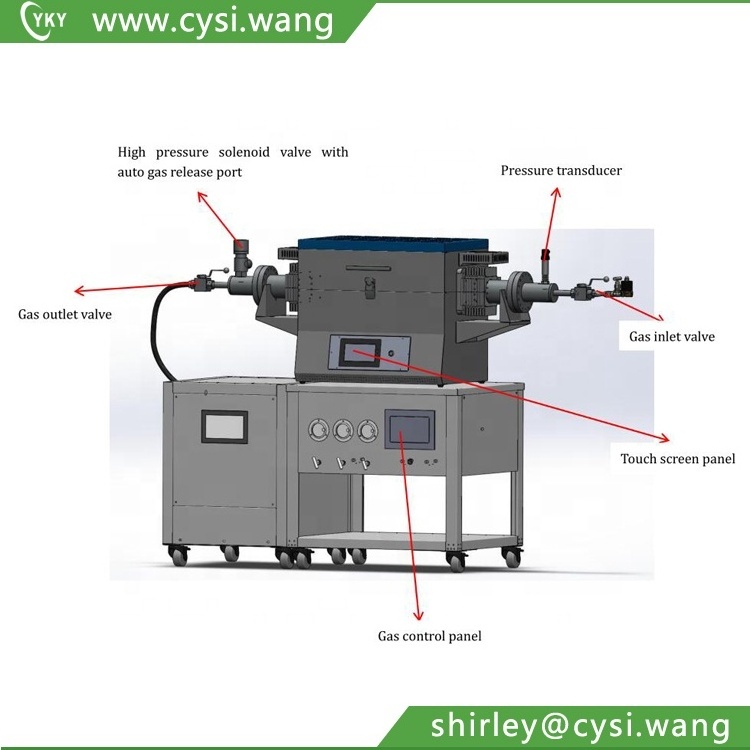

CY-HS1200-85I-T high temperature and high pressure tube furnace mainly consists of three parts: heating system, high temperature and high pressure resistant furnace tube and pressure measurement and control system.

High temperature and high pressure tube furnace can realize three functions of automatic stamping, overpressure release and automatic temperature control. It is equipped with process software, which can realize the whole process of data collection during the sintering process, and provide the most authentic and reliable basis for the analysis and research of experimental data.

The device can be widely used in high temperature and high pressure processing of nano materials, high temperature and high pressure sintering of special function ceramics, and the high temperature and high pressure modulation method is used to change the thermal property and electrical conductivity of the materials.

|

Item |

Detail |

|

Model |

CY-HS1200-85I-T |

|

Supply voltage |

AC220V/110V, 50Hz/60Hz |

|

Working temperature |

0~1100 ℃ |

|

Temperature control accuracy |

±1℃ |

|

Temperature control mode |

30 or 50 segment program temperature control |

|

Furnace tube diameter |

85mm |

|

Furnace tube length |

1000mm |

|

Furnace tube material |

Ultra-high temperature alloy |

|

Sealing method |

Pressure resistant CF flange |

|

Flange interface |

1/4" cutting sleeve joint (Ø8 pagoda joint) |

|

Vacuum |

4.4×10E-3Pa |

|

Pressure measurement |

Semiconductor pressure gauge |

|

Overvoltage protection |

Safety deflation valve |

|

Pressure regulation |

Manual electric free switching |

|

Heating zone |

Single heating zone 440mm long |

|

Work pressure |

≤20Mpa @800℃ ≤12Mpa @900℃ ≤6Mpa @1000℃ ≤4Mpa @1100℃ |

|

Display method |

LCD touch screen |

|

Working gas |

Non-corrosive gases such as nitrogen, argon, and oxygen |

1. Factory prices with the best quality.

2. One year free-of-charge maintenance for all the dental equipment

3. Customized service for special demand

4. Fast and flexible delivery, by sea, by air, by express

5. Quick response within 24 hours

How to order

1. If you are interested in our products, please tell us the model number and quantity.

2. We will make a proforma invoice for your order.

3. We will deliver the product ASAP on receipt of the payment

Guarantee

1. Guarantee for one year after shipment.

Payment

1. Western Union

2. PayPal

3. Secure Payment through Alibaba

4. Telegraphic transfer

5. L/C