- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

YJM

-

Item:

-

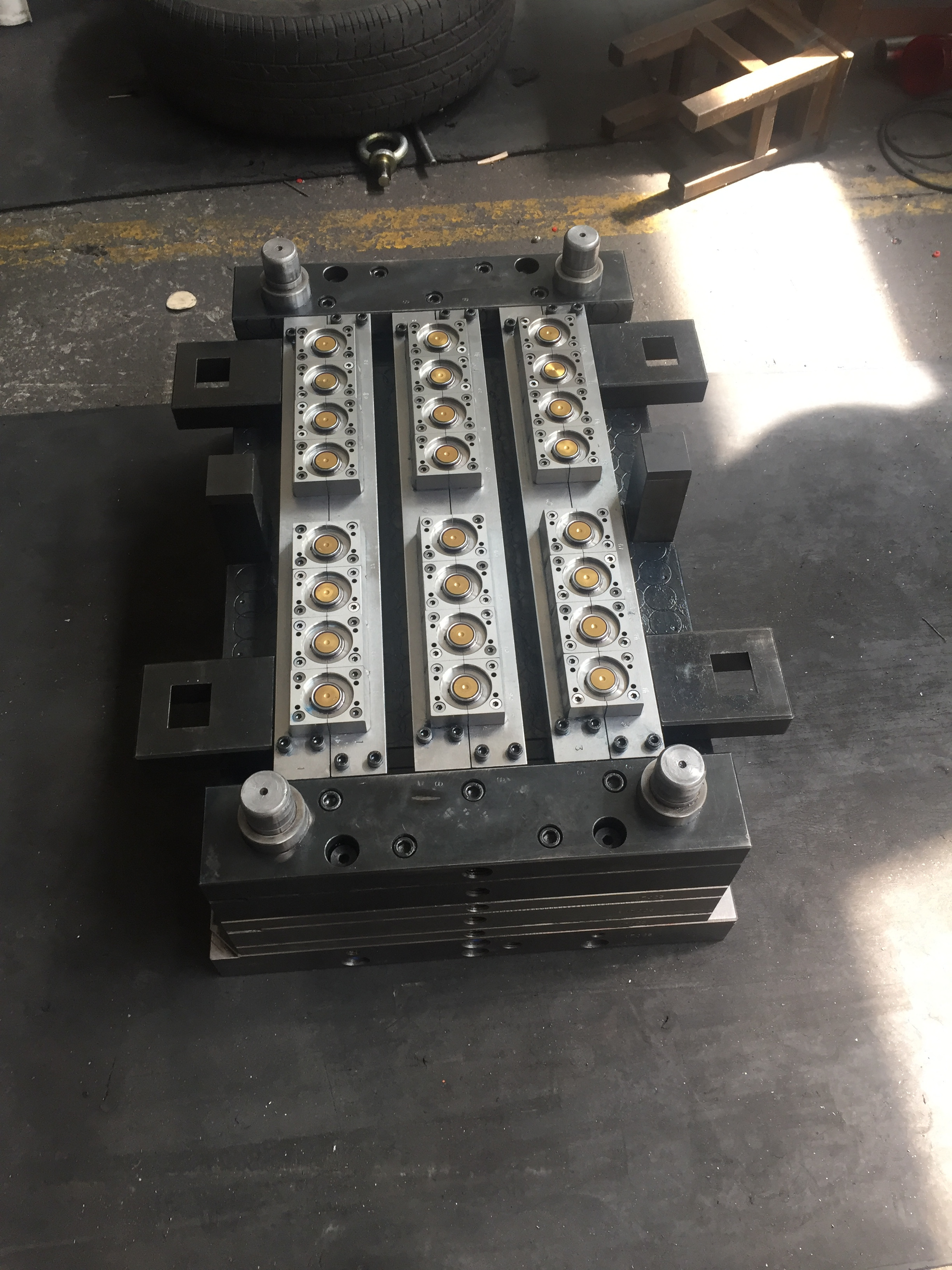

Huangyan Mold Design Needle Value without Tail 40 Cavities Cap Mold

-

Neck ring/Core/Cavity:

-

S136

-

Mould Base:

-

P20

-

Runner:

-

Hot Runner/Cold Runner

-

Mould Life:

-

300000-3000000shots

-

Useage:

-

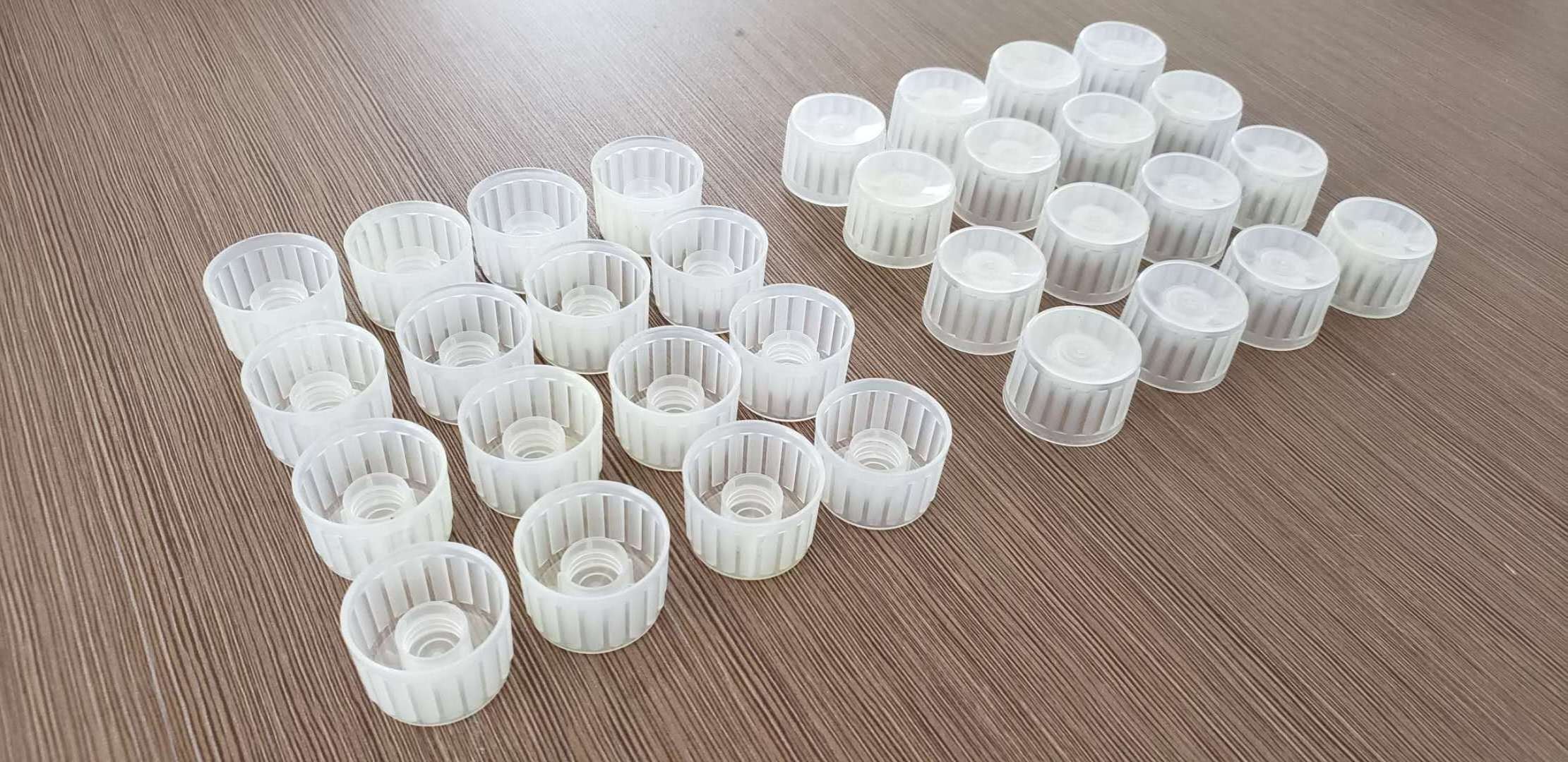

Water/Cosmetic/disinfectant Bottle

-

Feature:

-

Precise perform mould parts

-

Warranty:

-

1 Year

-

Application:

-

Household Product Mold

-

Design software:

-

CAD

Quick Details

-

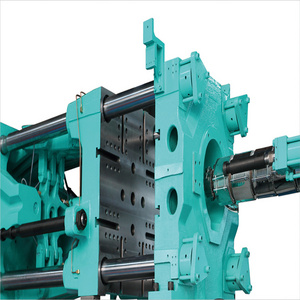

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Yanjun

-

Model Number:

-

YJM

-

Item:

-

Huangyan Mold Design Needle Value without Tail 40 Cavities Cap Mold

-

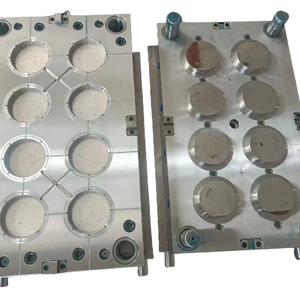

Neck ring/Core/Cavity:

-

S136

-

Mould Base:

-

P20

-

Runner:

-

Hot Runner/Cold Runner

-

Mould Life:

-

300000-3000000shots

-

Useage:

-

Water/Cosmetic/disinfectant Bottle

-

Feature:

-

Precise perform mould parts

-

Warranty:

-

1 Year

-

Application:

-

Household Product Mold

-

Design software:

-

CAD

|

After Warranty Service

|

|

|

|

Video technical support

|

|

|

|

Local Service Location

|

|

|

|

Place of Origin:

|

Zhejiang, China

|

|

|

Brand Name:

|

YANJUN

|

|

|

Model Number:

|

Customized

|

|

|

Shaping Mode:

|

Plastic Injection Mould

|

|

|

Product Material:

|

core and cavity: 2316, S136, H13, 718, SKD61, Mould base: P20, S50C, 45#steel

|

|

|

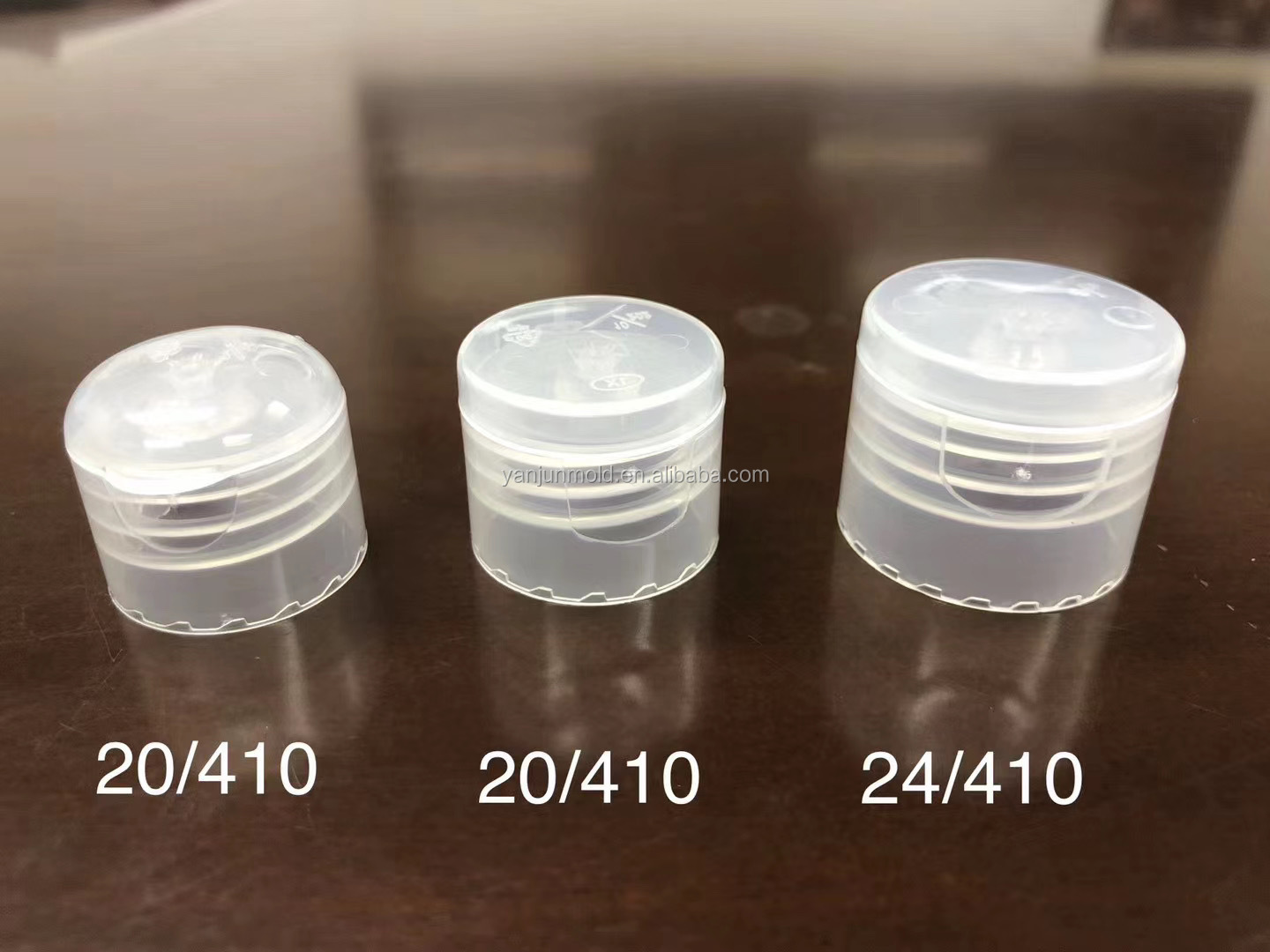

Product:

|

Bottle cap/ any cap

|

|

|

Cap mould runner:

|

Hot runner or cold runner system

|

|

|

Cap mould design software:

|

Ug,Proe,Solidworks, CAM, AotoCAD,Moldflow,ect

|

|

|

Cap mould surface treatment:

|

High polish or Electroplate treatment or painting

|

|

|

Cap mould processing:

|

CNC, Digital controller lathe

|

|

|

Cap Mould life:

|

2million shots at least

|

|

|

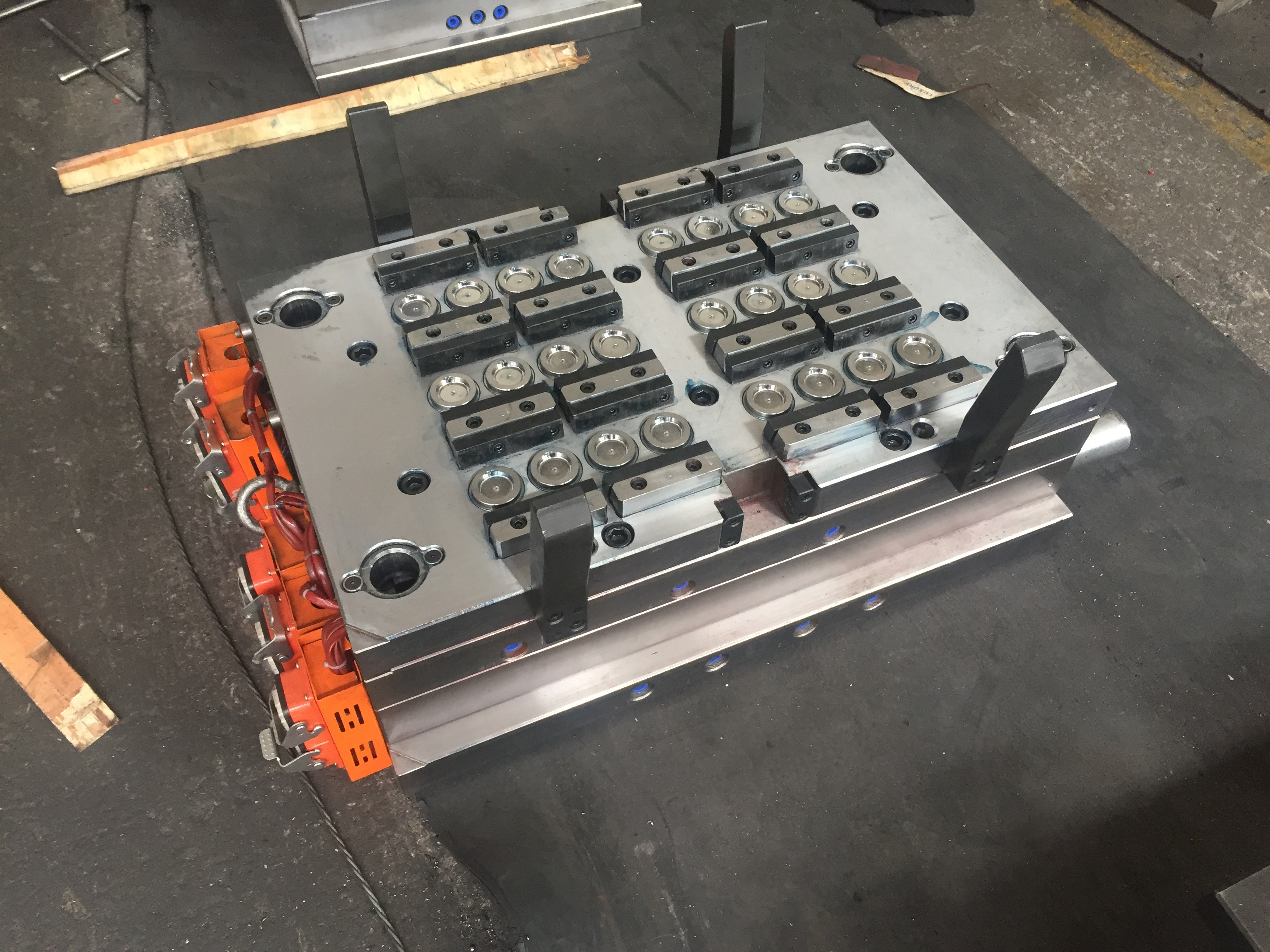

Cap mould gate type:

|

Pin gate, Submarine gate, Valve gate

|

|

|

Cap mould ejector type:

|

Unscrew by motor, stripper plate, ejector sleeve, ejector pin

|

|

|

Cap mould cycle time:

|

Based on cap design

|

|

|

Cap mould usage:

|

Produce plastic cap

|

|

|

Supply Ability 150 Set/Sets per year

|

|

|

|

Name

|

cap mould

|

|

|

Mould Material

|

core and cavity: 2316, S136, H13, 718, or SKD61, Mould base: P20, S50C, 45#steel

|

|

|

Product Material

|

PP,PE,PC,PA,PS,PU,PVC,PMMA,ABS etc

|

|

|

Cavity No.

|

Single or multi

|

|

|

System Of Runner

|

Hot runner,Cold runner

|

|

|

Ejector Type

|

Ejector pin,Air gate,Ejector plate,Hydro-cylinder,etc

|

|

|

Term Of Mould Production

|

40-60 working days

|

|

|

Guaranteed Number Of Cycles

|

1000000shots or one year

|

|

|

Mould Design Software

|

Ug,Proe,Solidworks, CAM, AotoCAD,Moldflow,ect

|

|

Step 1: Send the sample or drawing to us.

2. Design the product and mold

3. Confirm the drawing

4. Making mold

5. Test mould

6. Send the samples to customer

7. Confirm the sample and mould

8. Deliver the mould

Q:Can we get free Samples?

A:Yes,1-30 pcs free samples can be prvided for your referenceand testing on yourdelievery cost.lfyou need more samples,need to check with us.

Q:Can you produce customized color?

A:Yes,we can produce any coloryou need and there will be sample fee for cus-tomized color.Sample fee is depends on the color.

Q:How about theMOQ?

AlMOQ will be about 50,000pcs.

Q:Do you accept customized orders?

A:Yes,customized order will be acceptable.We have our own mold factory,couldset mold via the drawings confirmed by client and it will cost about 45-60 daysto set mold.Client will be responsible for the mold fee.

Q:Could mold fee be refund?

A:Yes,if order quantity reach 3 millon pieces within one year,we will refund you themould fee.

Hot Searches