- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

BJPFM

-

Application:

-

Industry

-

Belt Types:

-

chain plate

-

Color:

-

Nature

-

After Warranty Service:

-

No service

-

Local Service Location:

-

None

Quick Details

-

Applicable Industries:

-

Other

-

Weight (KG):

-

1

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

BJPFM

-

Application:

-

Industry

-

Belt Types:

-

chain plate

-

Color:

-

Nature

-

After Warranty Service:

-

No service

-

Local Service Location:

-

None

Customize 3mm/5mm paper making felt belt for Paper mill pulp filtration

1. Paper felt Conveyor Belt Overview

|

|

According to the use part of the paper machine, it can be divided into three categories: wet felt, upper felt and dryer felt. It is divided into plain weave and twill weave. Usually thicker in texture, dryer felts, also known as dry blankets, are used in the dryer section. The texture is the thickest, weighing more than 2000 grams per square meter. Has good strength. |

2. Paper Felt Conveyor Belt Details

|

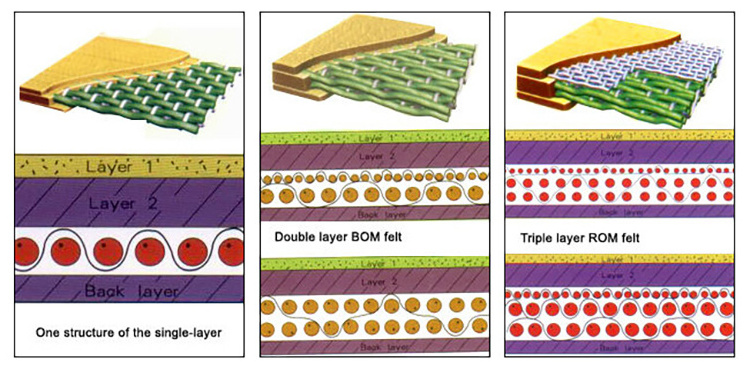

Papermaking felt are divided into two types: woven and knitted. |

|

| The woven paper felt is made of wool and nylon staple fiber blended yarn with a blending ratio of about 75:25, which is made by weaving, shrinking, raising, drying and setting. The manufacturing method of needle-punched papermaking felt is to first comb 50% wool and 50% nylon staple fiber or 100% nylon staple fiber into a fiber web, overlap multiple layers, and then use a barbed steel needle to stab the fiber web to the pre-woven fabric. On the annular base cloth, it can achieve a certain degree of tightness and flatness. | Acupuncture methods include single-sided acupuncture and double-sided acupuncture. Needle-punched felt has the characteristics of good water drainage, wear resistance, high strength and long service life. Used as a wool fabric for transferring wet sheets on paper machines. According to the use part of the paper machine, it can be divided into three categories: wet felt, upper felt and dryer felt. Wet felt is used in the press section, with a thin texture, easy to filter water, and weighs about 450~700 grams per square meter. |

|

| It is divided into plain weave and twill weave. The former filters water quickly, but it is easy to make obvious wool marks on the paper; the latter filters water slowly, but the wool marks are not obvious. The top felt is used in the Yangge dryer, twill weave, the surface is tight and smooth, and the wool must be burnt with a blowtorch to make the wet paper adhere to it. Usually the texture is thicker, weighing about 1000~1500 grams per square meter. Dryer felt, also known as dry blanket, is used in the dryer section. The texture is the thickest, weighing more than 2000 grams per square meter. Has good strength. Press the paper sheet tightly on the surface of the drying cylinder to heat evenly, and has the effect of ironing and smoothing. It is also replaced by a cotton canvas blanket. |

3. Paper Felt Conveyor Belt Features:

- Conductivity

- Softness

- Breathability

- Stable 1% fixed elongation rate

- Surface cut resistance

- Flexibility under operation

|

According to the position on the paper machine, it can be divided into wet felt, upper felt and dry felt. The wet felt runs with water on the paper machine, and its function is to press the blank to dewater and smooth the surface of the paper.

1. The wet felt has good water filtration and elasticity, high strength, small shrinkage, wear resistance, anti-bacteria and acid-base corrosion resistance.

2. The upper part of the felt is on the top of the wet felt, and a small part is in contact with the drying cylinder, which plays the role of paper collar, top leveling and drying. It has the properties of flatness, stiffness, good elasticity, wear resistance and high temperature resistance. |

| 3. The drying felt covers the drying cylinder and operates under wet heat and dry conditions. It irons and dries the paper, and has the properties of firmness, good elasticity, wear resistance and high temperature resistance. Dry felts can also be replaced by canvas or breathable fabrics woven from polyester filaments. |

Hole Sale