- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380/415V

-

Power:

-

100~200KW

-

Weight:

-

500 KG

-

Dimension(L*W*H):

-

2.2*2.2*2.5m

-

Year:

-

2023

-

Product name:

-

Lemon lime orange citrus squeezer presser juicer

-

Function:

-

Multifunctional

-

Material:

-

304 Stainless Steel

-

Usage:

-

Commercial Usage

-

Feature:

-

High Efficiency

-

Capacity:

-

500kg/h

-

Package:

-

Wooden Case

-

Color:

-

Silver

-

Operation:

-

Easily

-

Certification:

-

ISO/CE

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

BEYOND

-

Type:

-

PROCESSING MACHINE

-

Voltage:

-

380/415V

-

Power:

-

100~200KW

-

Weight:

-

500 KG

-

Dimension(L*W*H):

-

2.2*2.2*2.5m

-

Year:

-

2023

-

Product name:

-

Lemon lime orange citrus squeezer presser juicer

-

Function:

-

Multifunctional

-

Material:

-

304 Stainless Steel

-

Usage:

-

Commercial Usage

-

Feature:

-

High Efficiency

-

Capacity:

-

500kg/h

-

Package:

-

Wooden Case

-

Color:

-

Silver

-

Operation:

-

Easily

-

Certification:

-

ISO/CE

Lemon lime orange citrus squeezer presser juicer lemon peeler machine

Machine support designed with whole frame welding structure, good rigidity and small vibration.

Compact structure, small floor space, reliable operation; Optimized design of each component makes cleaning and replacement more convenient.All stainless steel manufacturing, comply with food hygiene standards.Installed in the processing line, automatic production with low labor intensity.

The press roller has protruding needles on the surface to grab the fruit.

The press roller and the sieve are half crescent shape, and the gap gradually decreases from large to small, which can squeeze the pulp well.

Automatic separation of fruit pulp and peel, high production capacity, the gap between extraction roll and filtration net will be adjusted according to different products.meet the requirements of production.

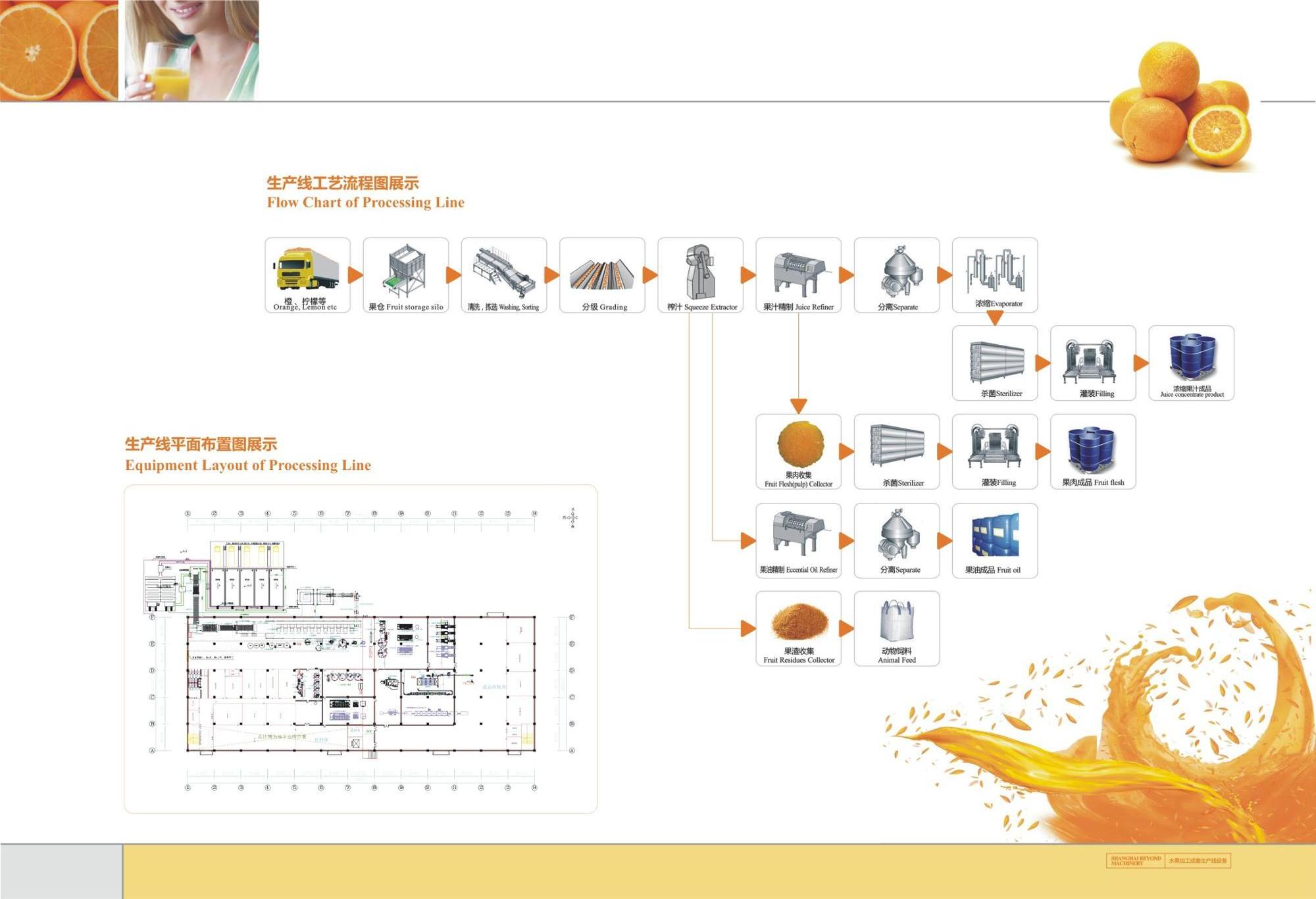

PRODUCTION LINE FEATURES

1. Wide range of raw fruits are available, this line is applicable for all kinds of orange society fruits with similar characteristic, such as citrus, lemon, pomelo, grapefruit etc.

2. Flexible configuration to make the line, according to different requirements for the end products, some exact equipments with different functions are flexible chosen, for example: debitterizing, deacidification, oil refiner, evaporation etc.

3. According to different investment value and product structure, client can require average, middle level or high level processing equipments.

4. End product with pure flavor, bright colour and high output percentage.

5. Whole line with features as high level automatical, low labour intensity, easy operation, safe function and low operation cost.

6. Whole line adopt sanitary design, can be cleaned thoroughly, with high level sanitation.

TECHNOLOGICAL FLOWCHART

CITRUS PROCESSING EQUIPMENT

Fruit ready to be extracted come from the procedure into the extractor feed hopper, from the feed hopper to the middle of two squeezing roller, needle shaped squeezing roller surface will be holding the fruit by extruding, in the process of extrusion, will contact with cutting knife, the cutting knife cut fruit, with the press roll rotation, the fruits keep turning, filtration net and pulp further squeeze, thus the pulp and peel to further separation.

Size Chart of This Design

|

Model

|

Capacity

|

Motor power:

|

Mechanical size

|

Extracting heads

|

|

ZZJ-5

|

5TPH

|

5.5KW,960r/min

|

1700*1670*1600mm

|

7 pcs/ drum

|

|

ZZJ-10

|

10TPH

|

9KW,960r/min

|

2200*2250*2800mm

|

7 pcs/ drum

|

Pre sales services

After-sale service

1.

Equipment warranty period

: We provide a one-year free warranty service for mechanical equipment. If any non-human caused problems occur during the warranty period, we will provide free repair or replacement services.

2.

Maintenance and upkeep services

: We provide regular or irregular equipment maintenance and upkeep services to ensure the normal operation of the equipment. We will provide 24-hour online technical support services.

3.

Accessory supply

: We guarantee to provide original factory accessories in a timely manner in case of equipment damage or replacement of parts.

4.

Training services

: In order to enable customers to effectively operate and maintain equipment, we will provide equipment operation and maintenance training.

5.

Installation and debugging

: We will provide equipment installation and debugging services to ensure that the equipment is installed correctly and can operate normally.