- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

5000

-

Weight (KG):

-

500 KG

-

Place of Origin:

-

ZHE

-

Brand Name:

-

Q&R

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

0.55 kW

-

Marketing Type:

-

Hot Product 2024

-

Function:

-

Mixing Raw Material

-

Certification:

-

CE,ISO9001,GMP

-

Capacity:

-

5-5000L

-

Nominal pressure:

-

-0.1MPa~0.8MPa

-

surface treatment:

-

Electrical polish,Mirror polish,Sand polish ,Aicd washing,2B

-

Homogenizer locate:

-

Bottom/Upper

-

Application scope:

-

High Viscosity Product

-

Heating method:

-

steam or Electric Heating

-

Homogenizer Speed:

-

0-3500 R/min

-

Mixing speed:

-

0-65 R/min

Quick Details

-

Barrel Volume (L):

-

5-5000

-

Max. Loading Volume (L):

-

5000 L

-

Range of Spindle Speed(r.p.m):

-

0 - 65 r.p.m

-

Max. Loading Capacity:

-

5000

-

Weight (KG):

-

500 KG

-

Place of Origin:

-

ZHE

-

Brand Name:

-

Q&R

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

0.55 kW

-

Marketing Type:

-

Hot Product 2024

-

Function:

-

Mixing Raw Material

-

Certification:

-

CE,ISO9001,GMP

-

Capacity:

-

5-5000L

-

Nominal pressure:

-

-0.1MPa~0.8MPa

-

surface treatment:

-

Electrical polish,Mirror polish,Sand polish ,Aicd washing,2B

-

Homogenizer locate:

-

Bottom/Upper

-

Application scope:

-

High Viscosity Product

-

Heating method:

-

steam or Electric Heating

-

Homogenizer Speed:

-

0-3500 R/min

-

Mixing speed:

-

0-65 R/min

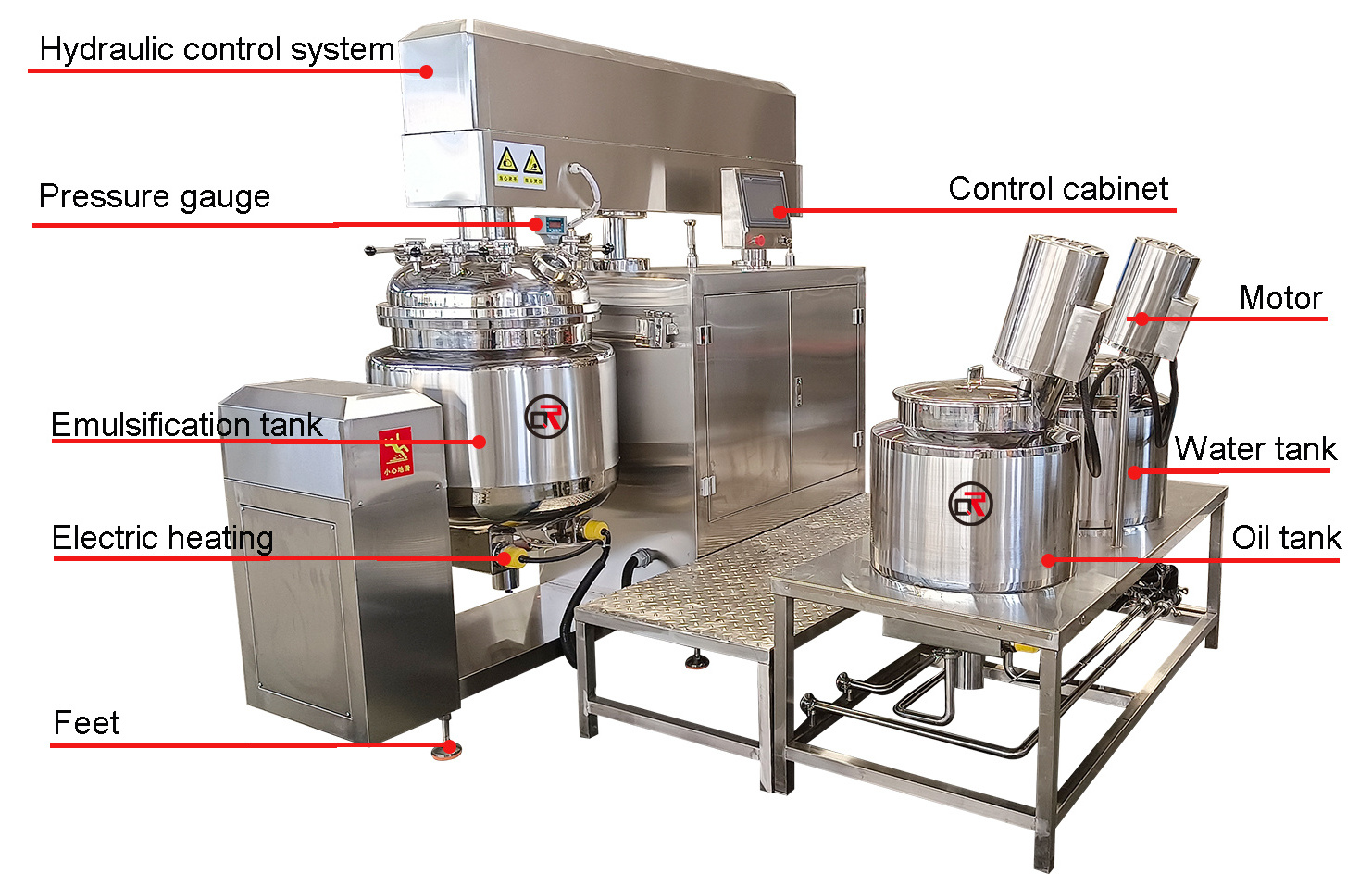

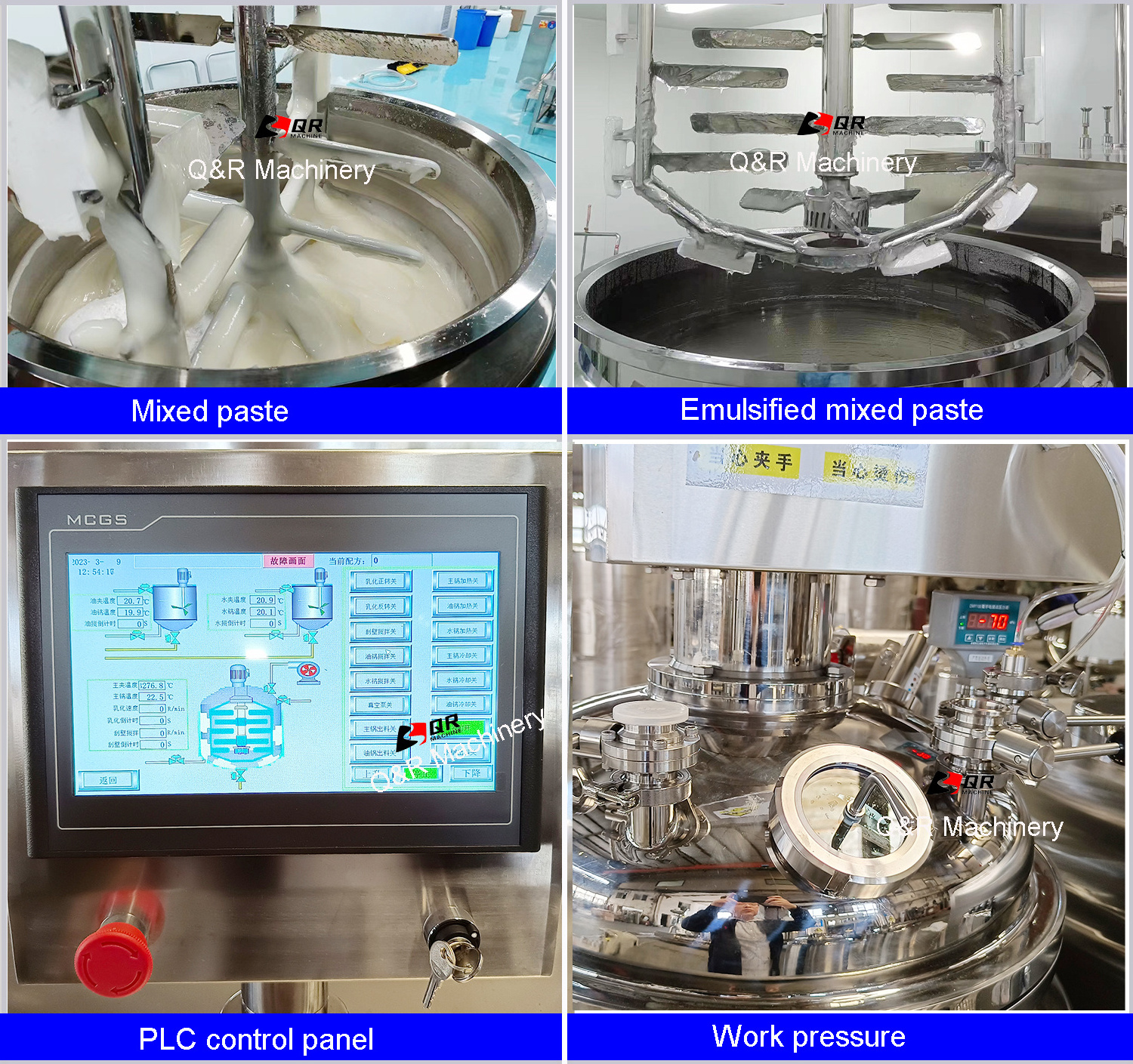

Product Description

|

Vacuum emulsification tanks

, widely used in

cosmetics, food, dairy,chemical and processing industries

Hygienic for

mixing, emulsifying, melting, high shear mixing and emulsifying tanks

standard.

|

|

|

|

Product Features:

1) Material: SUS304/ SUS 316L 2) Layer : Double layers/ three layers 3) Power : 0.37~55KW 4) Heating Type: electric/ steam heating |

Advantages:

1) Certificates: CE ,ISO, 3A 2) Warranty : 12 months 3) OEM/ODM: can design, exploitation and manufacture by CAD software and drawing. 4) Testing&QC: pressure test and material test |

|

|

Factory Scale:

1) Located in: Zhejiang, China 2) Factory Area: 5000SQ.M 3) Employees: 37 4) Production Ability : 100 Pieces/vacuum emulsification tank |

Delivery Time:

1) Material Preparation Time: 2 days 2) Metal Processing Time: 7-10 days, based on actrual quantity 3) Test & Packaging Time: 1 day |

|

Technical parameters:

|

Model

|

Capacity

|

Emulsifying Motor

|

|

Agitator

|

|

Vacuum Pump

|

|

Electirc Heating power/kw

|

Steam Heating Pressure /Mpa

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

Liter

|

KW

|

RPM

|

KW

|

RPM

|

KW

|

Ultimate Vacuum

|

|

|

|||||||||

|

VME-5

|

5

|

0.55

|

0-3600

|

0.4

|

0-65

|

0.37

|

-0.1 Mpa

|

6

|

0.2

|

|||||||||

|

VME-10

|

10

|

1.1

|

0-3600

|

0.55

|

0-65

|

0.37

|

-0.1 Mpa

|

6

|

0.2

|

|||||||||

|

VME-20

|

20

|

1.5

|

0-3600

|

0.55

|

0-65

|

0.37

|

-0.1 Mpa

|

9

|

0.2

|

|||||||||

|

VME-50

|

50

|

3

|

0-3600

|

0.75

|

0-65

|

0.75

|

-0.1 Mpa

|

12

|

0.2

|

|||||||||

|

VME-100

|

100

|

4

|

0-3600

|

1.5

|

0-65

|

1.5

|

-0.1 Mpa

|

24

|

0.2

|

|||||||||

|

VME-200

|

200

|

5.5

|

0-3600

|

1.5

|

0-65

|

2.2

|

-0.1 Mpa

|

28

|

0.2

|

|||||||||

|

VME-300

|

300

|

7.5

|

0-3600

|

3

|

0-65

|

2.2

|

-0.1 Mpa

|

32

|

0.2

|

|||||||||

|

VME-500

|

500

|

11

|

0-3600

|

4

|

0-65

|

4

|

-0.1 Mpa

|

50

|

0.2

|

|||||||||

|

VME-1000

|

1000

|

15

|

0-3600

|

5.5

|

0-65

|

4

|

-0.1 Mpa

|

54

|

0.2

|

|||||||||

|

VME-2000

|

2000

|

18.5

|

0-3600

|

7.5

|

0-65

|

5.5

|

-0.1 Mpa

|

recommend steam heating

|

0.2

|

|||||||||

|

VME-5000

|

5000

|

22.5

|

0-3600

|

11

|

0-65

|

7.5

|

-0.1 Mpa

|

|

0.2

|

|||||||||

|

The above is the reference data, different materials will have differences, can be

customized

.

|

|

|

|

|

|

|

|

|

|

|||||||||

In-tank agitators (stirrers), we have different types:

homogenizers, paddles, frames, anchors, dispersers, agitators

with scrapers.

All of our stainless steel tank can be Customized

Different types tank has different application

Stainless Steel Tanks : Storing Materials Stainless steel mixing/stirring tanks : mixing or shearing materials Stainless steel milk storage tank/milk cooling and sterilizing tank : milk sterilization, high-pressure emulsification, storage, cooling Stainless steel vacuum emulsification tank/melting tank : vacuum emulsification tank Stainless steel fermenter : beer fermentation.

Stainless Steel Tanks : Storing Materials Stainless steel mixing/stirring tanks : mixing or shearing materials Stainless steel milk storage tank/milk cooling and sterilizing tank : milk sterilization, high-pressure emulsification, storage, cooling Stainless steel vacuum emulsification tank/melting tank : vacuum emulsification tank Stainless steel fermenter : beer fermentation.

Applications

Recommend Products

Workshop corner

Why Choose Us

Quality engineering

FAQ

1:Are you manufacturer?

Yes, we are. Welcome to visit our factory.

2:Can you change the machine voltage as our request?

Yes, we can.

3: How about the delivery time?

With the standard products delivery time will be15-35 days after we receive your payment.

4: What's the payment terms?

Usually is T/T, L/C, or Western Union. We also accept Money Gram, PayPal and other payment terms.

5: Where are the main markets for your products?

Products have been exported to all over the world, especially in Northern Europe Western Europe, Eastern Europe North American,

South American, Middle East, South Asia, Eastern Asia, African and etc.

Yes, we are. Welcome to visit our factory.

2:Can you change the machine voltage as our request?

Yes, we can.

3: How about the delivery time?

With the standard products delivery time will be15-35 days after we receive your payment.

4: What's the payment terms?

Usually is T/T, L/C, or Western Union. We also accept Money Gram, PayPal and other payment terms.

5: Where are the main markets for your products?

Products have been exported to all over the world, especially in Northern Europe Western Europe, Eastern Europe North American,

South American, Middle East, South Asia, Eastern Asia, African and etc.

Inquiry Now

Hot Searches