- Product Details

- {{item.text}}

Quick Details

-

Capacity:

-

2-25T/h

-

Power:

-

0.5kw

-

Weight:

-

360kg

-

Material:

-

Caroban Steel

-

Dimension:

-

1640*1210*1322mm

-

Voltage:

-

220/380V

Quick Details

-

Name:

-

Grain Destoner Machine

-

Application:

-

Cereal Grains

-

Color:

-

Customized

-

Capacity:

-

2-25T/h

-

Power:

-

0.5kw

-

Weight:

-

360kg

-

Material:

-

Caroban Steel

-

Dimension:

-

1640*1210*1322mm

-

Voltage:

-

220/380V

Product Description

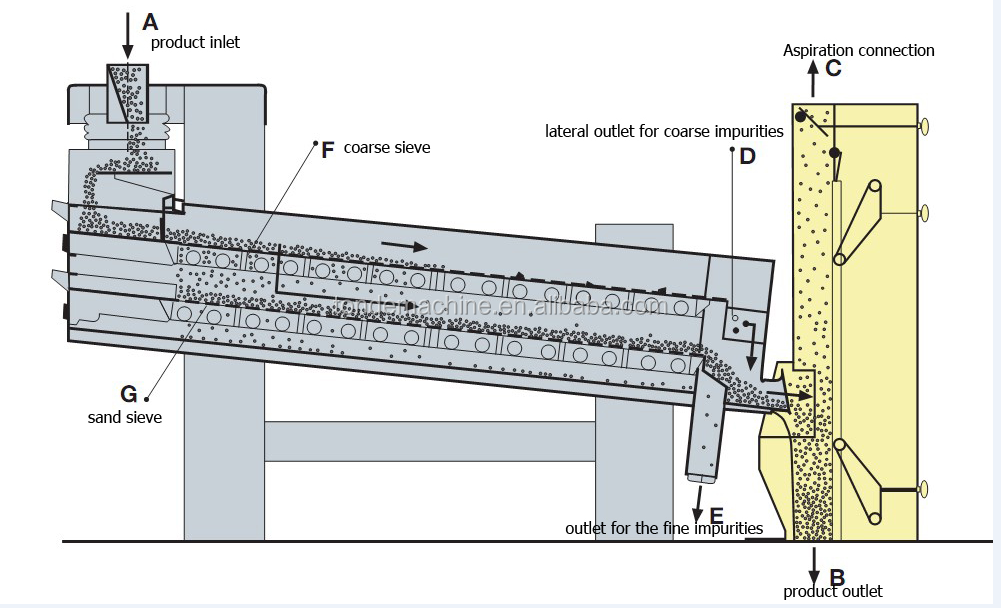

Application of Vibration Grain Cleaning Machine :

Vibration Grain Cleaning Machine is applied for grain cleaning primarily in wheat, maize, rice mills or in grain storage facilities. The machine also serves successfully in feed mills, seed cleaning plants and oil seeds cleaning plants. Using sieves, the cleaner removes coarse and fine impurities from the grain. It also grades a wide range of different materials according to size.

High throughput capacity and excellent separation.

High throughput capacity and excellent separation.

Employing a separation system with sieves, the Vibration Grain Cleaning Machine frees the grain of coarse impurities such as large kernels, strings, straw, wood, stones and clods of soil, and from fine impurities like sand or broken grains. High throughput capacities of up to 30 t/h in cleaning and 120 t/h in grain storage facilities (silos), as well as an outstanding separation effect ensure the highest efficiency in grain cleaning.

Optionally, an aspiration channel or air recycling aspirator can be employed to remove low-density particles such as dust, hull fragments or husks, thereby optimizing the cleaning effect.

Employing a separation system with sieves, the Vibration Grain Cleaning Machine frees the grain of coarse impurities such as large kernels, strings, straw, wood, stones and clods of soil, and from fine impurities like sand or broken grains. High throughput capacities of up to 30 t/h in cleaning and 120 t/h in grain storage facilities (silos), as well as an outstanding separation effect ensure the highest efficiency in grain cleaning.

Optionally, an aspiration channel or air recycling aspirator can be employed to remove low-density particles such as dust, hull fragments or husks, thereby optimizing the cleaning effect.

Minimal maintenance required thanks to sturdy design.

The amount of maintenance required by the Vibration Grain Cleaning Machine is kept to a minimum thanks to fast and easily changeable sieves, easily exchangeable wear parts and the absence of lubrication points.

A cleaning function employing rubber balls provides constant and effective cleaning of the sieves during the entire process: This results in less maintenance and a higher throughput capacity.

Thanks to the unit's robust design, wear is significantly reduced.

A cleaning function employing rubber balls provides constant and effective cleaning of the sieves during the entire process: This results in less maintenance and a higher throughput capacity.

Thanks to the unit's robust design, wear is significantly reduced.

Different aspiration systems for flexible application.

The Vibration Grain Cleaning Machine can be combined with various aspiration systems and is therefore extremely flexible in its application.

Product Paramenters

Details Images

Hot Searches