- Product Details

- {{item.text}}

Quick Details

-

Power:

-

800-20000kw

-

Dimension(L*W*H):

-

According to the actual conditions

-

Weight:

-

1000 kg

-

Product name:

-

Turnkey cement plant construction plant setup cost

-

Capacity:

-

50tpd to 3000tpd

-

Spares Parts:

-

supply for one year freely

-

Energy-Saving:

-

35%

-

Application:

-

cement plant

-

Installation:

-

Under Engineer Guidance

-

Fuel:

-

Pulverized Coal, Gas

-

Type:

-

Cement Plant

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZK

-

Voltage:

-

380V or according to customer

-

Power:

-

800-20000kw

-

Dimension(L*W*H):

-

According to the actual conditions

-

Weight:

-

1000 kg

-

Product name:

-

Turnkey cement plant construction plant setup cost

-

Capacity:

-

50tpd to 3000tpd

-

Spares Parts:

-

supply for one year freely

-

Energy-Saving:

-

35%

-

Application:

-

cement plant

-

Installation:

-

Under Engineer Guidance

-

Fuel:

-

Pulverized Coal, Gas

-

Type:

-

Cement Plant

China New 3000tpd 42.5 Portland Cement Factory Limestone Rotary Kiln

We Henan Zhengzhou Mining machinery Co.,Ltd. (ZK Corp.) offer one-stop service for you, including designing, suitable equipment providing, installing and debugging, technical serving, and reliable after-sales service. And we have successfully finished the construction of cement production lines of 3000t/d, 2500t/d, 1500t/d, 600t/d, 300t/d and 150t/d.

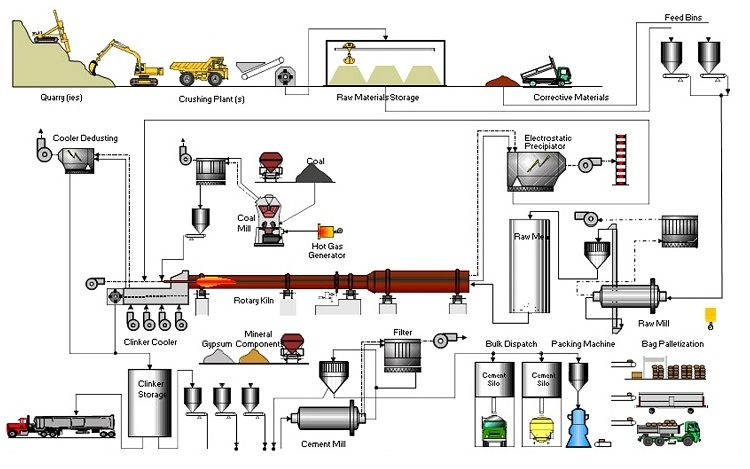

Cement Plant Production Process

Mined limestone is transported by conveyors to the crusher for crushing. Crushed limestone is ground by ball mill or vertical mill into powder, and then transported by conveyor to the raw material silo for storage and further mixing. After homogenization, raw material goes into the preheating system for decomposition. The decomposition rate is about 95%. After calcined in the rotary kiln, raw material becomes clinker. Clinker, gypsum, and other mixed materials are ground in ball mill into cement of qualified fineness. Powder separator is used to adjust fineness of cement to achieve energy-saving production. Packaging machine and automatic loading machine are used to pack and deliver bags of cement.