- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

frosted glass

-

Thickness:

-

4mm

-

Color:

-

Blue,green,bronze,pink,black

-

Material Type:

-

clear float glass,patterned glass,low iron glass

-

Size:

-

Custom design

-

Tolerance:

-

+/- 0.2mm

-

Edge:

-

rough,polished,flat,round,pencil,beveled

-

Certificate:

-

AS/NZS2208,CCC,CE,ISO

-

Frosted Method:

-

acid etched ,sand blasted

-

Delivery of frosted glass:

-

within 7-10 days after deposited

-

Available Process of frosted glass:

-

cut,grind,drill,silkscreen printing,frosted,acid etched

Quick Details

-

Application:

-

Hotel

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

frosted glass

-

Model Number:

-

frosted glass

-

Thickness:

-

4mm

-

Color:

-

Blue,green,bronze,pink,black

-

Material Type:

-

clear float glass,patterned glass,low iron glass

-

Size:

-

Custom design

-

Tolerance:

-

+/- 0.2mm

-

Edge:

-

rough,polished,flat,round,pencil,beveled

-

Certificate:

-

AS/NZS2208,CCC,CE,ISO

-

Frosted Method:

-

acid etched ,sand blasted

-

Delivery of frosted glass:

-

within 7-10 days after deposited

-

Available Process of frosted glass:

-

cut,grind,drill,silkscreen printing,frosted,acid etched

Frosted glass

is produced by the

sandblasting

or

acid etching

of clear sheet

glass

. It has the effect of rendering the glass

translucent

by

scattering

of light during transmission, thus

blurring

images while still transmitting light.

Features of Frosted Glass/Frosted Glass Bathroom Window/Frosted Glass Bathroom Door :

- A smooth and sweet white hue to the glass surface, reflectively emitting a soft light.

- Perfect for adding privacy in shower areas.

- Added Privacy

- Distinctive and smooth

- Satin-like appearance

- Admits Soft Light

- One side is etched, other side is smooth for Easy Cleaning

- Perfect for Designer Patterns

-

Methods of Frosted Glass/Frosted Glass Bathroom Window/Frosted Glass Bathroom Door :

Acid-Etched Frosted Glass is created with the use of abrasives (acid treatment) to create the signature Frosted Glass look.

Sandblasted Frosted Glass is created with a high speed machine that bombards the glass panel with sand, walnut husks or other materials.

| Method | Process | Advantage | Applications |

| Acid-Etched Frosted Glass |

created with the use of abrasives (acid treatment) |

produces a “true” frosted look and more uniform and smoother to the touch |

Coffee table ,dining table and so on furniture where you will touch often |

| Sandblasted Frosted Glass |

created with a high speed machine that bombards the glass panel with sand, walnut husks or other materials |

offers versatility in creating design effects. | Bathroom door,Bathroom window,Room partitions,where you need beautiful design |

Edge of Frosted Glass/Frosted Glass Bathroom Window/Frosted Glass Bathroom Door :

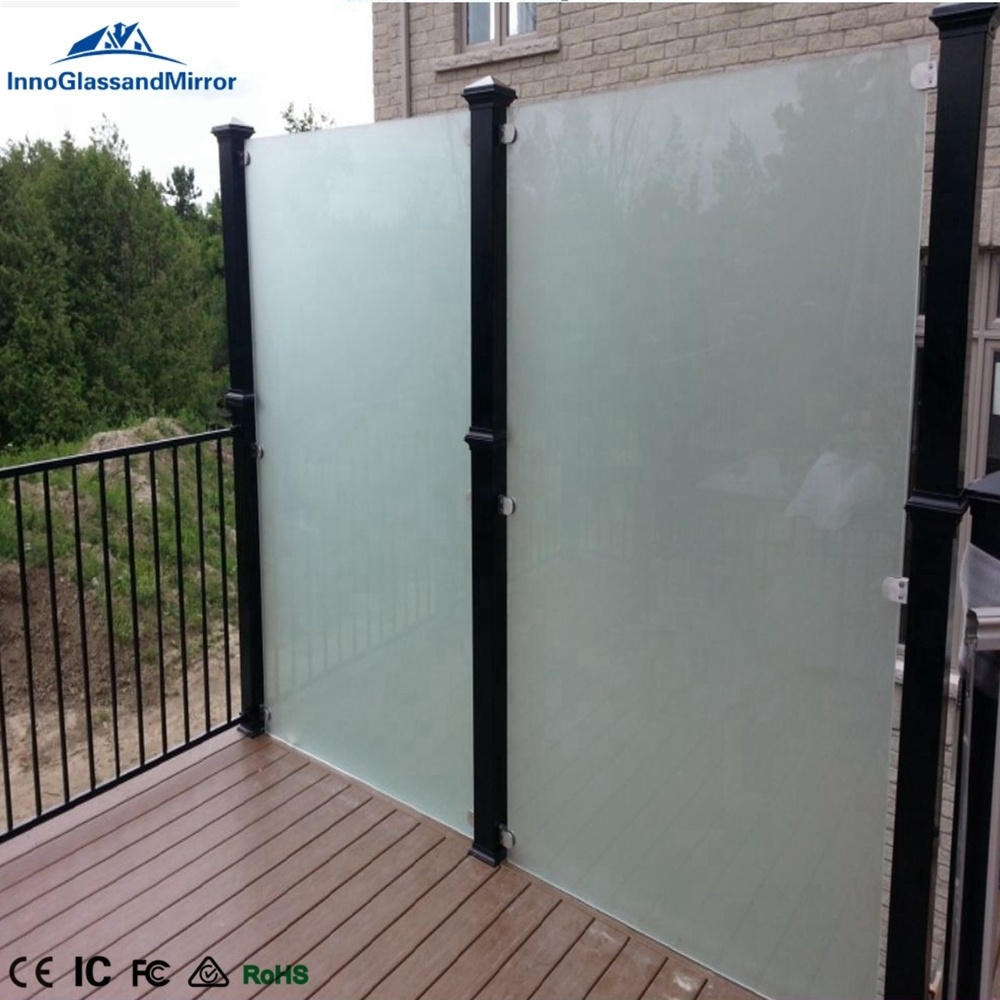

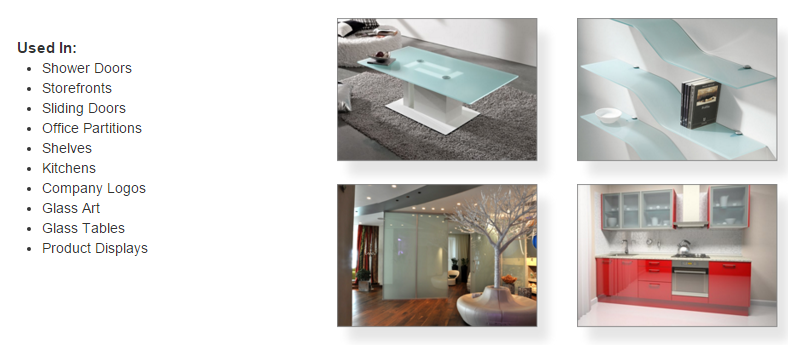

Applications of Acid Etched Frosted Glass and Sandblasted Frosted Glass:

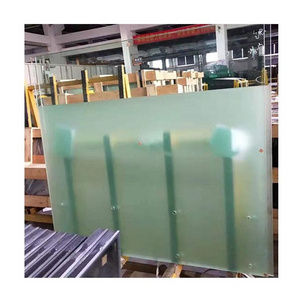

Production line of Acid Etched Frosted Glass and Sandblasted Frosted Glass:

Sandblasted Line

Background on Tempered Glass :

Follow us to see how we tempered the glass to customer design:

1.Cut the glass into the desired shape first.

This has to be done before the glass is tempered, as the tempering process will weaken the glass if it is cut or etched afterward and may increase the likelihood of breakage.

2.Inspect the glass for imperfections. Cracks or bubbles may cause the glass to break during tempering; if any are found, the glass cannot be tempered.

3.Grind the cut edges smooth. This removes any burrs created during cutting or etching.

4.Wash the glass. This removes any tiny grains of glass deposited during sanding, as well as any dirt that may interfere with the tempering process.

5.Heat the glass in a tempering oven. Glass may be fed in batches or continuously. The oven reaches temperatures of over 600 degrees Celsius (1,112 degrees Fahrenheit), with the industry standard being 620 degrees Celsius (1,148 degrees Fahrenheit).

Usual Settings of Tempered Glass

|

Products |

Tempered glass | ||||||||

| Thickness | 3mm,4mm,5mm,6mm,8mm,10mm,12mm,15mm,19mm | ||||||||

| Sizes | MIN:20MM*20MM MAX :3600*12000MM | ||||||||

| Tolerance:+/-0.2mm | |||||||||

| Specification | a) Surface treatment: acid etched,frosted,silkscreen printing | ||||||||

| b) Thickness from 3mm-25mm | |||||||||

| c) Color :clear,low-iron,F green,ocean blue,Fort blue,and other tinted glass | |||||||||

| d) Edge :Flat edge,grind edge,High polished edge,bevelled edge and others | |||||||||

| e) Corne r:natural corner,grind corner,round corner with fine polished | |||||||||

| f) Holes :Drill work available at customer's option | |||||||||

| Feature | 1.4-5times stronger than annealed glass of the same thickness | ||||||||

| 2.Stronger resistance to thermal breakage than annealed or heat strenghtned glass | |||||||||

| 3.If breakage occurs the glass breaks up into small, cubical fragments, which are not threatening to humans | |||||||||

| 4.Suitalbe for use as a safety glass as defined by consumer product safety association | |||||||||

| Delivery details | Within 10-15 days after receiving your deposit | ||||||||

| Packing details | 1.interlay paper or plastic between two sheets 2 .seaworthy wooden crates | ||||||||

| 3 .iron belt for consolidation | |||||||||

| Quality standard | CE certificate,AS/NZS certificate,3Ccertificate and Fire-proof | ||||||||

| Payment terms | 30%T/T in advance,balance before the shipment or by L/C. | ||||||||

InnoGlass Technology (Qingdao) Co.,Ltd is a professional glass manufacture with strong technology research and development ability ,

Our main products including wide ranges:

The smart switchable PDLC glass and film, transparent LCD display ,

Silkscreen printing glass,home appliance glass,furniture glass,

Tempered glass,mirror,solar glass,low-e glass etc.

For the silkscreen printing glass, we achieve colorful, super adhesion combined specializing in high demand products,for example home appliances panels, decorative glass , furniture glass and so on !

On the switchable smart PDLC glass film, Inno-glass cooperate with Korea factory based on our own research and development to achieve ultra- thin , UV resistant, high transmittance, oversized products by hardening , coating , laminating , plastic folders and other production processes

For the Transparent LCD display,totally innovative products, they can be used for Showcase,

advertising,building,fridge door and so on;

Our advantages:

1. Strong technology research team;

2. Advanced equipment guarantee the quality of products;

3. Perfect quality products meet ISO9000,3C,CE,etc;

4. Professional management team, based on customers need, design and manufacture products, creating value for customers ;

5. Customer first has always been our service concept;

1.What is the MOQ?

The MOQ is 2-10 Pieces

2.Can we design the size,logo and edge?

Of course you can,actually,it's the most important,YOUR IDEA !

3.How long can I get the sample if need?

Within 3-7 days depends on the process way

4.How can we contact with you?