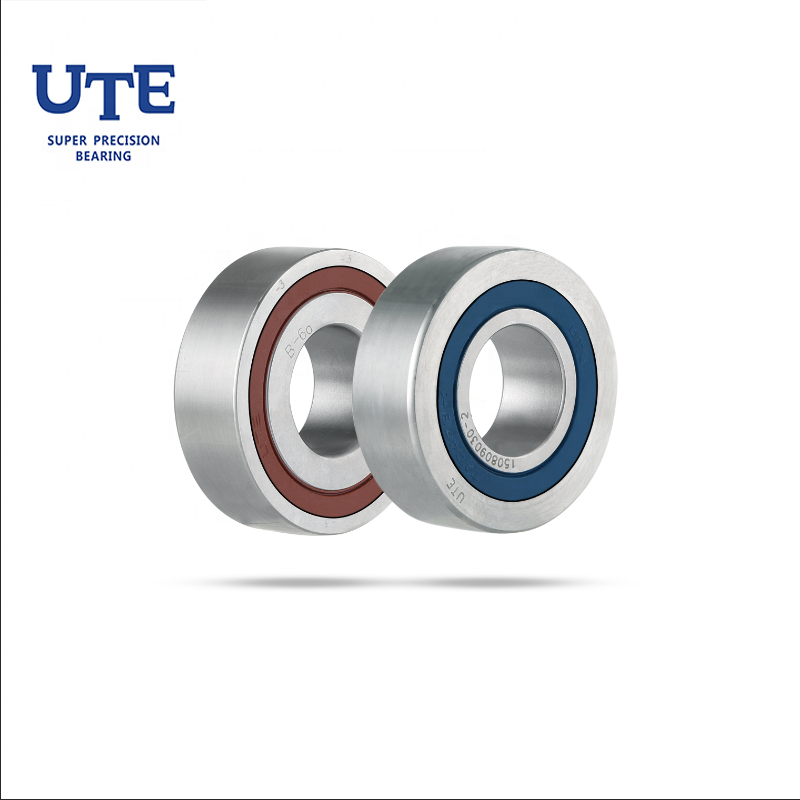

Zhejiang UTE Ltd Co., located at Taizhou, Zhejiang, is a national high-tech enterprise with RMB 6.98 million registered capital specialized in producing precision angular contact ball bearings. The company has 12 automatic manufacture lines of precision angular contact ball bearings pioneered in China, which have the capacity to produce up to 3 million sets of P4 and P2 precision angular contact ball bearings with inner diameter of 3mm-100mm per year. It has 500 specifications of products covering many industry areas, such as precision machine, high speed spindle, advanced medical equipment, aerospace and instrument etc. It is the most competitive enterprise in Chinese precision angular contact ball bearing industry. The company, identified as a national high-tech enterprise, has provincial technology R & D center and engineering center. It also is the member of China Rolling Bearing Standardization Committee and has made a lot of national and industrial standards for precision angular contact ball bearings.

The company, founded in 1987, was (before 2001) Taizhou Special Bearing Factory, related to Luoyang Bearing Research Institute of National Ministry of Machine-Building Industry. Relying on the Institute, the company participated in many national and provincial key science and technology development projects, including special bearings for aviation and aerospace and provincial key scientific and technological projects and major projects, and has developed a series of high speed, high precision and new bearing products with special performance, of which many fill the product and technology gap in China. Its self-developed bearing unit for precision medical equiment and high speed spindle bearing for precision CNC machine has won support from "National Innovation Fund Project" , the high speed precision ceramic ball bearing and specialized bearing assembly for new X ray tube and CT machine and so on are listed into "China Torch Program".

Through thirty years of exploration, accumulation and development, the company has mastered core technologies in main links covering product design, precision manufacture, inspection and test and host application. In addition to providing quality products, the company can also provide comprehensive technical consultative service and personalized and differentiated integrated solutions for bearing application under variety of complex environment.

Adhering to the development concept of "quality first, technology leading, customer oriented" , the company will always adhere to the road of specialty, precision, peculiarity and novelty and work hard for the best in the field of precision angular contract ball bearing to become a unique outstanding enterprise with global reputation.