- Product Details

- {{item.text}}

Quick Details

Quick Details

-

Place of Origin:

-

China

-

Product name:

-

ball mill liner

High Chrome and Manganese ball mill liner

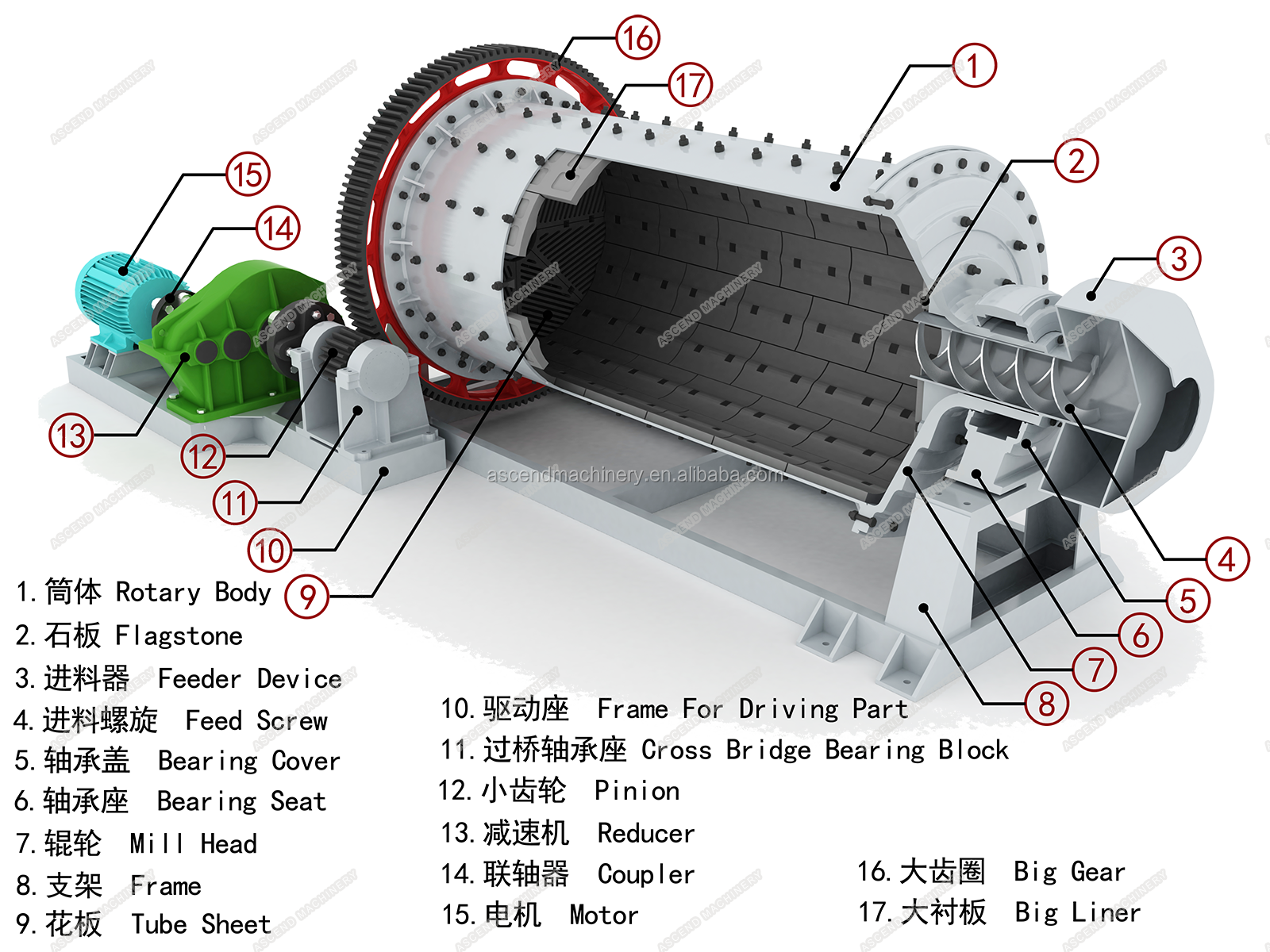

The ball mill is suitable for grinding various ores and other materials. It is widely used in mineral processing, building materials and chemical industries. It can be divided into dry and wet grinding methods. According to different mining methods, it can be divided into two types: lattice type and overflow type. The ball mill main wear parts is ball mill liner and steel balls. We can offer ball mill liner OEM casting according to spare parts drawings. If possible, we can also send engineers to customer site for spare parts mapping!

The main components of ball mill can be clearly shown in the following pictures:

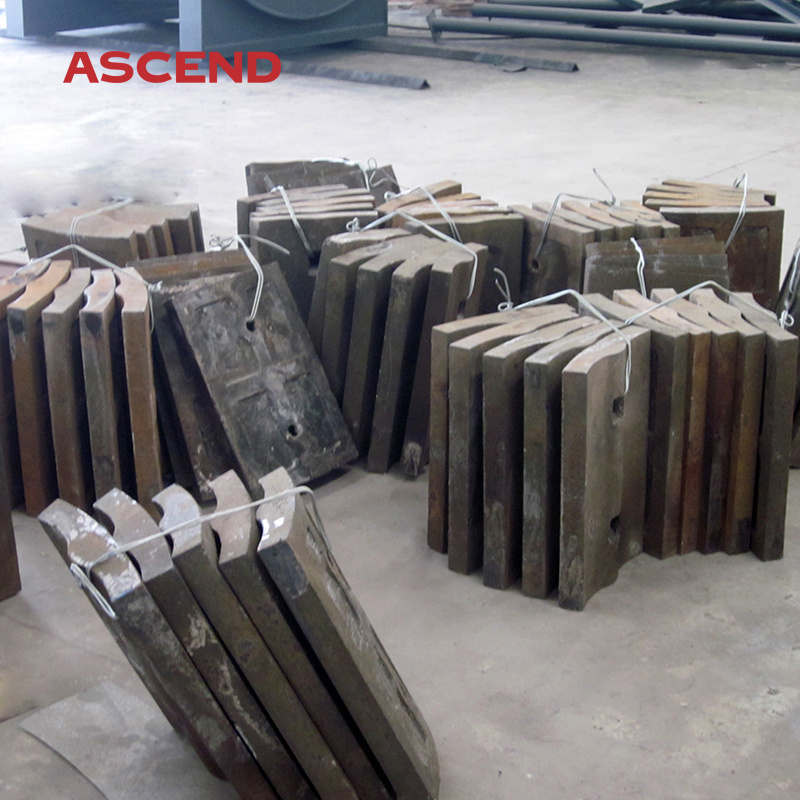

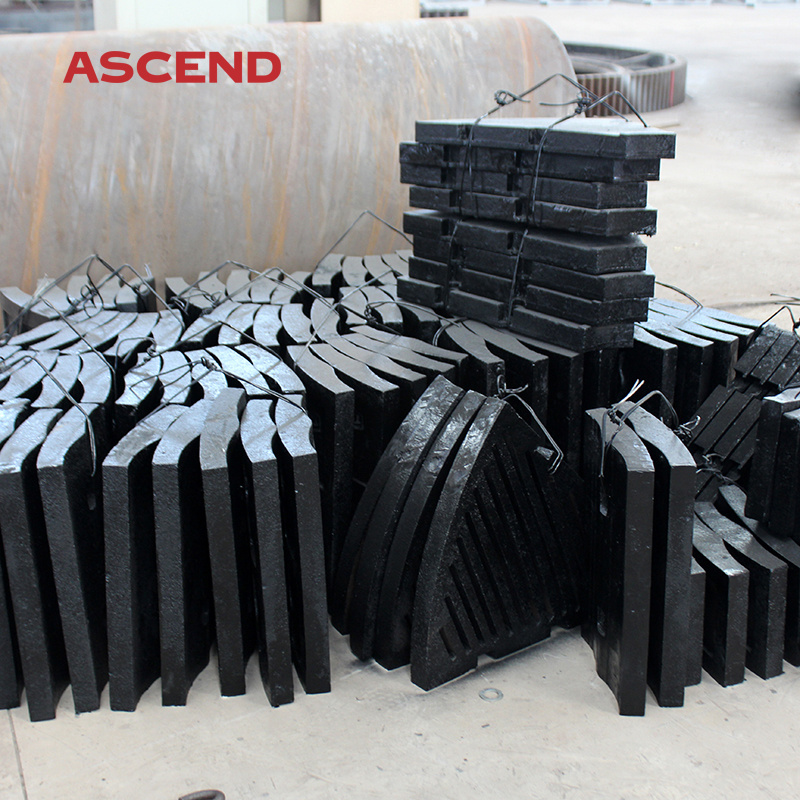

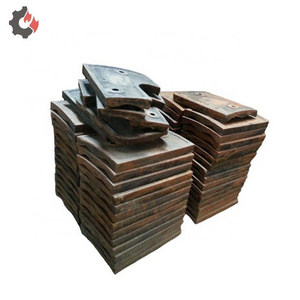

Ball mill liner description

Ball mill liners is to protect the cylinder from suffering direct hit from grinding medium and material and friction,to increase grinding medium for material crushing effect, helps to improve the efficiency of the grinding mill, increase production, reduce consumption of metal. D ifferent types of mill liners can be used to adjust the movement of materials.

Product Features:

l Material: High Manganese Steel, Super-High Manganese Steel, High Chromium Casting Iron, Alloy Steel, Chromium-molybdenum Steel,or as per the customer requests.

l Hardness: as per your request.

l Impact Value: as per your request.

l Tensile Strength: as per your request.

l Heat Treatment Process: Normalizing, Tempering, Quenching & Tempering.

l Surface treatment: rust preventive oil, or as per your requests.

Advantages:

l ISO9001:2008 Standard certified

l Custom-made design

l High abrasion resistance

l Long service duration

l Easy and fast installation and replacement

l OEM and ODM are available.

OEM Casting Service

When customer place order on the ball mill liner, it is better they can offer the parts drawing, then we can do the casting job. If customer can not offer, we can send our engineer to customer site for spare parts drawing mapping. The following is the ball mill liner drawing sample:

Production process

Q1: Are you trading company or manufacturer?

A: We are factory.

Q2: How long is your delivery time?

A: Generally it is 7-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q3: What is your payment method?

A: 30% of total price should be paid by T/T as down payment; 70% balance payment should be paid by T/T before delivery.

Q4: What Information should customers give us, So that we can be able to provide you suitable quotation and service.

What minerals are you separating?

What's the maximum size of your raw minerals?

How much capacity do you need per hour for your project?

A: The warranty period of crusher equipments is one year. and we will supply the spare parts for you at lowest cost.