- Product Details

- {{item.text}}

Quick Details

-

certificate:

-

CE

-

Finished product:

-

deformed bars, round bars, angle bars, channel bars, flat bars

-

After sales service provided:

-

Service Machinery Overseas

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

rolling type:

-

full continuous rolling

-

annual capacity:

-

50000T-300000T

-

certificate:

-

CE

-

Finished product:

-

deformed bars, round bars, angle bars, channel bars, flat bars

-

After sales service provided:

-

Service Machinery Overseas

Company Introduction

Wuxi Bolong Machinery Co.,Ltd is an an integrated professional metallurgy machinery manufacturer in designing and producing continuous casting machine, hot rolling mill production line. Our company is competent to undertake turnkey metallurgical project including project design, manufacture, installation, commissioning and after-sales service. Our products are covered all kinds of continuous casting machine with radius from 3 meters to 13 meters, such as round billet, square billets and slabs; various specifications of Roughing Mill, Intermediate Rolling Mill, Finishing mill could be designed and manufactured to produce deformed bar, wire rod with the diameter 8mm-40mm.

Factory Building

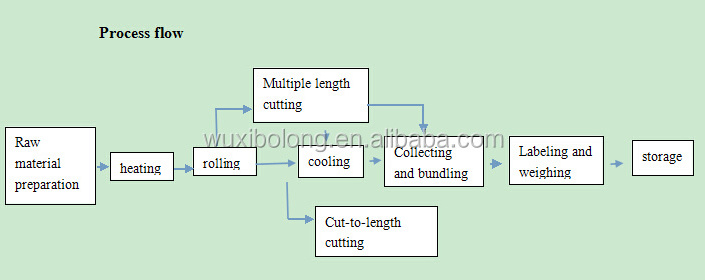

Process Introduction:

Qualified cold billet lifted to charging roller table by crane to arrive at furnace end of reheating furnace, then to be pushed into reheating furnace for heating by billet pusher. When billet temperature reaches to 1150-1250℃, billet will be pushed out of furnace by billet-out device; via furnace out roller table and working roller table before rolling mill, billet will go into rough rolling mill, intermediate rolling mill and finish rolling mill step by step. The final products will go through remained heat treatment device and be cut by multiple-length flying shear and then arrive to cooling bed for cooling by cooling bed entering device after speed-up roller table. After cooling, by cooling bed exit device, the products will be transferred to run-out roller table, and then go to cut-to-length shear. After cut-to-length cutting and inspection, the final products will be transferred to final product span from final product cross span inspection bracket and then being collected, bundled, weighed, labeled and finally stored.

Reheating furnace

Hot billet out from reheating furnace

Rough rolling mill, intermediate rolling mill and finish rolling mill

Cooling bed

Flying shear

Electric control equipment

Engineering Team

Contact information

|

Company |

Wuxi Bolong Machinery Co.,Ltd |

|

Address |

North, Hudai Industrial Park, Binhu District, Wuxi City |

|

Zip |

214161 |

|

Telephone |

86 510 8558 1378/3868 |

|

Fax |

86 510 8558 1378 |