- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

2mm

-

Voltage:

-

220V50Hz/380V60Hz

-

Place of Origin:

-

Jiangsu,China

-

Brand Name:

-

Jinri Packing Machinery

-

Dimension(L*W*H):

-

2100*1500*2150

-

Weight:

-

2200 KG

-

Product Name:

-

water filling line

-

capacity:

-

4000BPH

-

Processing Types:

-

rinsing filling and capping

-

bottle type:

-

PET bottle

-

bottle volume:

-

200-1500ml

-

material:

-

SUS304/316

-

filling accuracy:

-

2mm

-

Certification:

-

CE ISO

-

customizable:

-

yes

-

After sale service provided:

-

yes

Quick Details

-

Machinery Capacity:

-

4000BPH

-

Packaging Material:

-

Plastic, Metal, Wood

-

Filling Material:

-

Water

-

Filling Accuracy:

-

2mm

-

Voltage:

-

220V50Hz/380V60Hz

-

Place of Origin:

-

Jiangsu,China

-

Brand Name:

-

Jinri Packing Machinery

-

Dimension(L*W*H):

-

2100*1500*2150

-

Weight:

-

2200 KG

-

Product Name:

-

water filling line

-

capacity:

-

4000BPH

-

Processing Types:

-

rinsing filling and capping

-

bottle type:

-

PET bottle

-

bottle volume:

-

200-1500ml

-

material:

-

SUS304/316

-

filling accuracy:

-

2mm

-

Certification:

-

CE ISO

-

customizable:

-

yes

-

After sale service provided:

-

yes

Zhangjiagang Jinri Packaging Machinery Co., Ltd.

Zhangjiagang Jinri Packaging Machinery Co., Ltd.

is a professional manufacturer of beverage machinery in China.Our main products have: Water filling production line, juice filling production line, carbonated drinks filling production line, and also aerosol filling machine, 5 Gallon bottle filling production line, and all other auxiliary equipment.

Our engineers are located all over the world and can provide safe and fast service to your beverage production solutions in your country.

Product Description

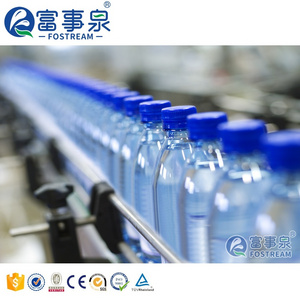

CGF14-12-4 Water Filling Machine

Automatic water rinser filler capper 3-in-1 filling Triblock, combined with rinsing, filling and capping. It is innovated and designed in the requirement of carbonated soft drinks, beer, energy drink, and soda water, on the basis of introducing, digesting and absorbing advanced technology from Germany.

The machine is a full-automatic multiple-function washing, filling and capping unit. It is used in washing. filling and sealing all kinds of carbonated drinks such as beer, soft drink, energy drink mineral water and pure water. The line has features of unique design,new style, complete functions,multi-purpose, convenient in operation, compact construction, high automaticity. It is the best filling equipment in China.

The machine is a full-automatic multiple-function washing, filling and capping unit. It is used in washing. filling and sealing all kinds of carbonated drinks such as beer, soft drink, energy drink mineral water and pure water. The line has features of unique design,new style, complete functions,multi-purpose, convenient in operation, compact construction, high automaticity. It is the best filling equipment in China.

1. Rinser.

The high efficiency atomizing spay nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and also saves rinsing water.

2. Capper.

Cap distributing chute is equipped with a photocell switch to stop the capper when there is no cap inside the chute.

Specification

|

Model

|

Rinsing heads

|

Filling heads

|

Capping heads

|

Capacity(BPH)

|

Motor Power(KW)

|

Dimension(mm)

|

Weight(kg)

|

|

CGF14-12-4

|

14

|

12

|

4

|

4000

|

2.2

|

2100X1500X2200

|

2000

|

|

CGF18-18-6

|

18

|

18

|

6

|

6000

|

3.5

|

2300X1700X2400

|

2500

|

|

CGF24-24-8

|

24

|

24

|

8

|

10000

|

4.5

|

2800X2200X2400

|

3500

|

|

CGF32-32-10

|

32

|

32

|

10

|

12000

|

6.0

|

2900X2200X2500

|

5500

|

|

CGF40-40-12

|

40

|

40

|

12

|

18000

|

7.5

|

3600X2700X2850

|

7500

|

|

CGF50-50-15

|

50

|

50

|

15

|

22000

|

9.5

|

5300X3200X2850

|

9000

|

|

CGF60-60-15

|

60

|

60

|

15

|

25000

|

11.2

|

5600X4500X2850

|

12000

|

|

CGF70-70-18

|

70

|

70

|

18

|

28000

|

15.0

|

6000X4800X2850

|

15000

|

|

CGF80-80-18

|

80

|

80

|

18

|

35000

|

18.0

|

6500X5000X2850

|

18000

|

Water Treatment System.

1 - Raw water tank + Raw water pump

2 - Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter

3 - Reverse Osmosis (one level)

4 - UV sterilizer

5 - Finished water tank + Pure water pump

1 - Raw water tank + Raw water pump

2 - Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter

3 - Reverse Osmosis (one level)

4 - UV sterilizer

5 - Finished water tank + Pure water pump

Blowing Machine.

1 -

This model of fully automatic rotary blow molding machinery is specially designed for high speed based on absorbing all international latest technology, it is mainly used in producing pure water bottle and carbonated soft drink bottle.

Filling Machine.

1 - Enhanced food safety: Stainless steel 304/316L for all components in contact with your beverage

2 - Optimum uptime: 30 % reduction in changeover and maintenance downtime

1 - Enhanced food safety: Stainless steel 304/316L for all components in contact with your beverage

2 - Optimum uptime: 30 % reduction in changeover and maintenance downtime

Bottle dryer machine.

1- This machine is reliable, stable and can be used in the production line with high speed.

2- The wind direction is adjustable. The wind mouth can also be adjusted according to actual situation.

3- Almost every kind and size of bottles can be dried by this machine.

4 - Low energy cost.

5 - No easy-wear accessories or parts.

1- This machine is reliable, stable and can be used in the production line with high speed.

2- The wind direction is adjustable. The wind mouth can also be adjusted according to actual situation.

3- Almost every kind and size of bottles can be dried by this machine.

4 - Low energy cost.

5 - No easy-wear accessories or parts.

Labeling Machine.

1-Boasting four carousel sizes, up to three labelling stations and 24 configurations, can generate outputs of up to 72,000 containers per hour, when standalone, at an efficiency rate of 98%.

1-Boasting four carousel sizes, up to three labelling stations and 24 configurations, can generate outputs of up to 72,000 containers per hour, when standalone, at an efficiency rate of 98%.

Packing System.

1 - Pack consistency and quality

2 - Gentle and precise infeed configuration

3 - Flexible handling of multiple SKUs

4 - Automatic pack and raw material changeovers

2 - Gentle and precise infeed configuration

3 - Flexible handling of multiple SKUs

4 - Automatic pack and raw material changeovers

Hot Searches