- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Maximum input power:

-

25KW

-

maximum temperature:

-

1800℃

-

working voltage:

-

AC380V 50Hz

-

Quartz tube:

-

150mm(OD)X142mm(ID)X450mm(H)

-

control accuracy:

-

+/-5℃

Quick Details

-

Warranty:

-

1 years

-

Brand Name:

-

RSE

-

Model Number:

-

RSE- NGL-1800, RSE- SP25-D

-

Place of Origin:

-

Guangdong, China

-

Maximum input power:

-

25KW

-

maximum temperature:

-

1800℃

-

working voltage:

-

AC380V 50Hz

-

Quartz tube:

-

150mm(OD)X142mm(ID)X450mm(H)

-

control accuracy:

-

+/-5℃

PRODUCT DESCRIPTION

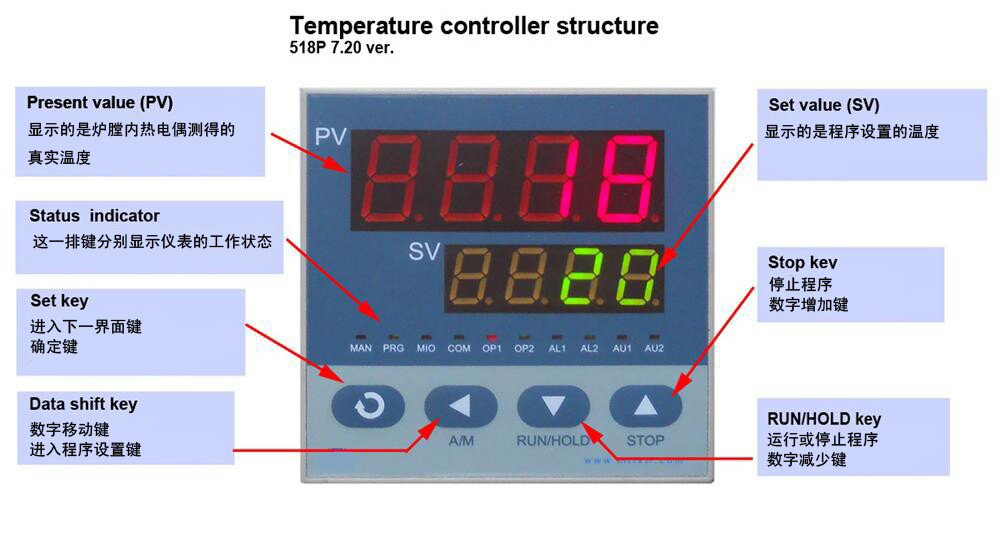

Software control system (optional): The furnace is equipped with communication interfaces and software, which can directly control various parameters of the furnace through a computer. The PV and SV temperature values on the furnace and the operation of the instruments can be observed from the computer. The actual temperature rise curve of the furnace will be plotted in real time by the computer, and the temperature data at each time can be saved, which can be called up at any time.

SPECIFICATION

|

Product model

|

SP25-D

|

|

|

|

|||

|

Equipment advantages

|

Equipment advantages

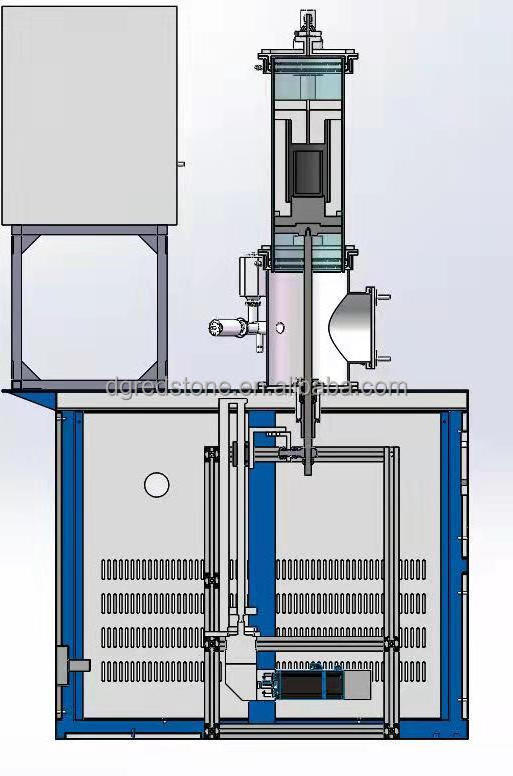

1. Compact structure, compact appearance, covering an area of 1 square meter

2. After setting parameters on the touch screen, the device automatically runs with a high degree of automation

3. Side door opening for easy access to materials

4. It can be used as smelting furnace and Directional solidification furnace

5. Various safety protections have been implemented, including over temperature, under water, couple interruption, overcurrent, overvoltage alarms, etc.

|

|

|

|

|||

|

Maximum output power

|

25KW

|

|

|

|

|||

|

maximum temperature

|

1800℃

|

|

|

|

|||

|

Copper ring size

|

174mm(OD)X150mm(ID)X130mm(H)

|

|

|

|

|||

|

Dimensions of high-purity graphite crucibles

|

60mm(OD)X50mm(ID)X85mm(H)

|

|

|

|

|||

|

Quartz tube

|

150mm(OD)X142mm(ID)X450mm(H)

|

|

|

|

|||

|

Thermocouple

|

Tungsten rhenium

|

|

|

|

|||

|

Heating method

|

induction heating

|

|

|

|

|||

|

working voltage

|

380VAC 50HZ

|

|

|

|

|||

|

Power oscillation frequency

|

30-80KHZ

|

|

|

|

|||

|

Heating current of high-frequency power supply

|

2~52A

|

|

|

|

|||

|

Cooling water requirements

|

≥0.2MPa≥6L/min

|

|

|

|

|||

|

protect

|

Equipped with protection for under water pressure, overheating, and over power

|

|

|

|

|||

|

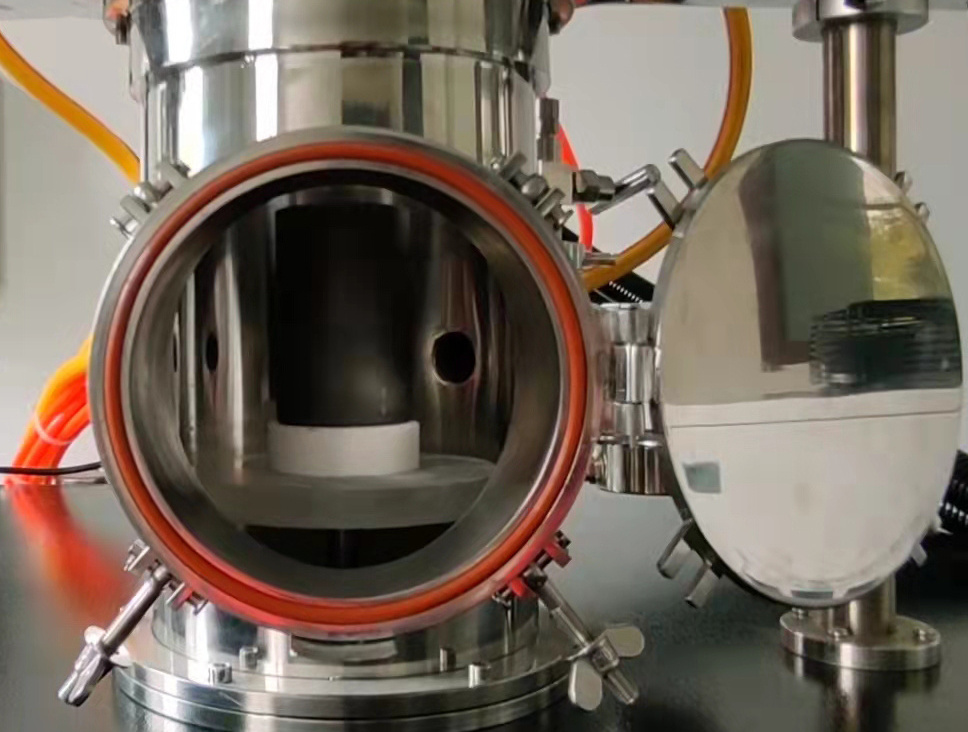

Lower vacuum flange

|

The lower stainless steel flange is welded with a vacuum chamber, and a furnace door is opened on the vacuum chamber. Materials can be taken from the furnace door. The chamber is welded with KF25 connector, KF16 interface, and intake valve. A vacuum baffle valve is installed on the KF25 connector, and a 1-meter long corrugated pipe is connected to the valve and vacuum pump. The KF16 interface can be connected to a vacuum gauge

|

|

|

|

|||

|

Upper vacuum flange

|

The upper vacuum flange is equipped with thermocouples and outlet valves, which can program temperature rise of materials

|

|

|

|

|||

|

Temperature control system and thermocouple

|

Adopting PID control, the material can be programmatically controlled for temperature heating, and the current output can be manually adjusted at the same time. The equipment is equipped with over temperature protection

|

|

|

|

|||

|

control accuracy

|

+/-5℃

|

|

|

|

|||

|

Vacuum pump

|

Pumping rate

|

|

40L/S

|

|

|||

|

|

Extreme vacuum degree

|

|

1Pa

|

|

|||

|

Resistance vacuum gauge

|

power

|

|

|

|

|||

|

|

Vacuum measurement range

|

|

0.1-10 5 Pa

|

|

|||

|

|

Resistive silicon

|

|

ZJ-52T

|

|

|||

|

Water cooler (optional)

|

temperature range

|

|

5-30℃

|

|

|||

|

|

Water flow rate

|

|

16L/m

|

|

|||

|

|

Water tank capacity

|

|

12Liters

|

|

|||

Materials can be transported to the heating area through an automatic lifting platform, and after being lowered, they can be taken out from the furnace door.

1. Lift platform travel 300mm

2. The lifting speed of the lifting platform is 0.1um-2000um/s

3. The lifting platform can be lifted automatically, manually, or at multiple speeds

4. The lifting platform is limited both up and down, providing maximum protection for the equipment

5. It is very convenient to place and retrieve materials

Design scheme

1. The induction coil is equipped with a graphite bucket, and the graphite crucible is placed on the lifting platform. A lifting rod is installed below the lifting platform, which is driven by a motor to move up and down

2. After the material is melted in the graphite crucible, the graphite crucible slowly moves downwards under the action of the motor. There is a temperature field between the graphite crucible and the graphite barrel inside the induction coil

3. The melted material rearranges its lattice within this temperature field, growing crystals in the direction of the seed crystal

FAQ

Q. Are you a manufacturer or a trading company?

A. We are professional laboratory instrument manufacturers, have their own design team and factory, have mature technical experience, and can guarantee the quality of products and the optimal price.

Q. Our country's power supply and plug are different. How do you solve it?

A. We can supply a transformer and plug according to your local requirements according to the power plug of different countries.

Q. How long is your delivery time? If I want to customize the instrument, how long does it take?

A.1. lf the goods are in stock, it is 5-10 days. 2. We can provide customized services for our customers. It usually takes 30-60 days depending on the specifications of the custom instrument.

Q. How to pay?

A.T/T, LIC, D/P, etc., it is recommended to use Alibaba Trade Guarantee.

Q.How is the package of goods? Delivery methods?

A.1. Standard export fumigation sign wooden box packaging

2. Express, air, sea shipping according to customer requirements, find the most suitable way.also accept LC at sight.

Hot Searches