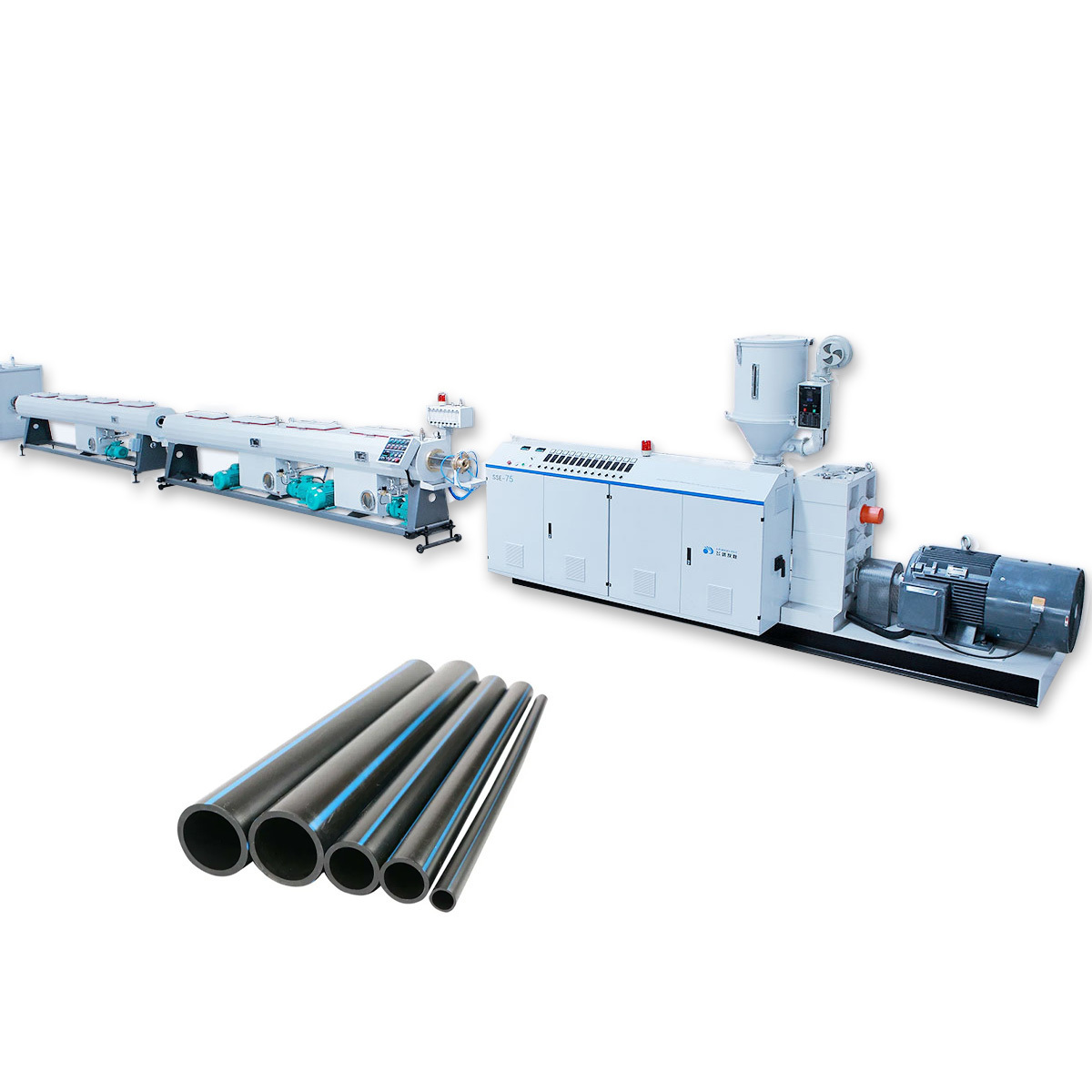

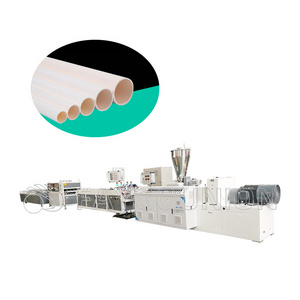

>>The pipe has some excellent features such as heating resistant, aging resistant, high mechanical strength, environmental stress cracks resistant, good creep resistant, etc. our extrusion line is designed with high efficiency extruder and equipped with reducer which is high speed and low noise, Gravimetric dosing unit and ultrasonic thickness indicator can be assembled according to customer's demand to ascend the precise of the pipes .

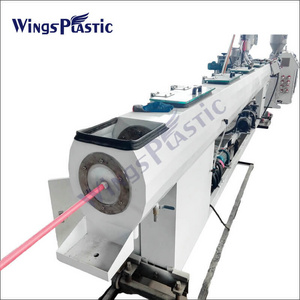

>>Turn key solution can be provided, like laser printer crusher, shredder, water chiller, air compressor etc. to achieve

high-grade and automatic tube production.

>>Turn key solution can be provided, like laser printer crusher, shredder, water chiller, air compressor etc. to achieve

high-grade and automatic tube production.

>>Process Flow:

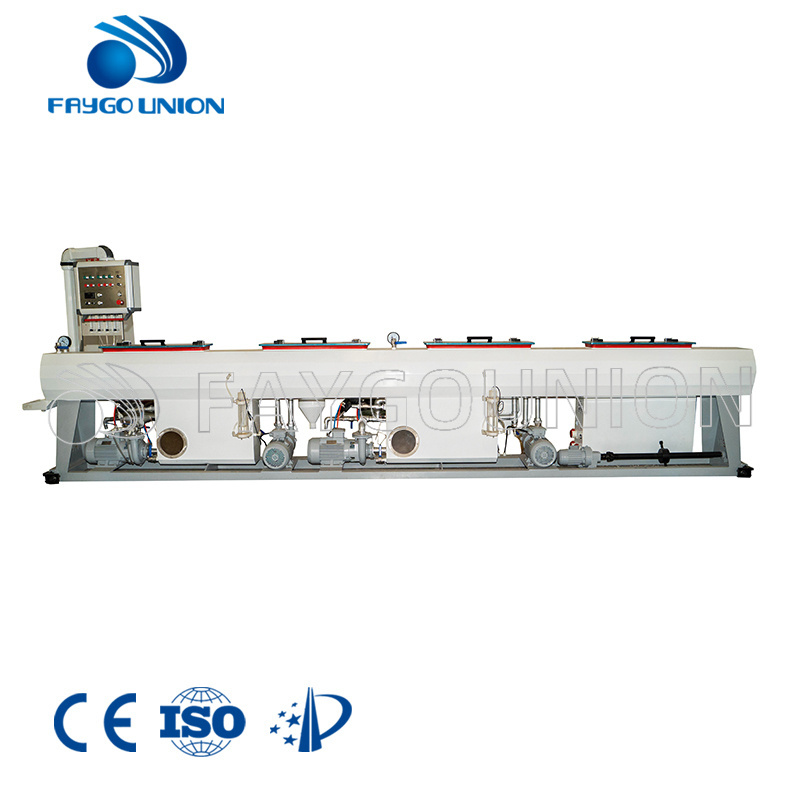

Raw material+ Master Batches → Mixing → Vacuum Feeder →Plastic Hopper Drier→ Single screw extruder →Co-extruder for color string & Multi Layers → Mold → Vacuum Calibration Tank → Spray Cooling Water Tank → Haul-off → No Dust Cutter →Double/Single disc Winding / Stacker → Final Product Inspecting &Packing