- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

500kg

-

Productivity:

-

30-70kg/h

-

Weight (KG):

-

500 kg

-

Product name:

-

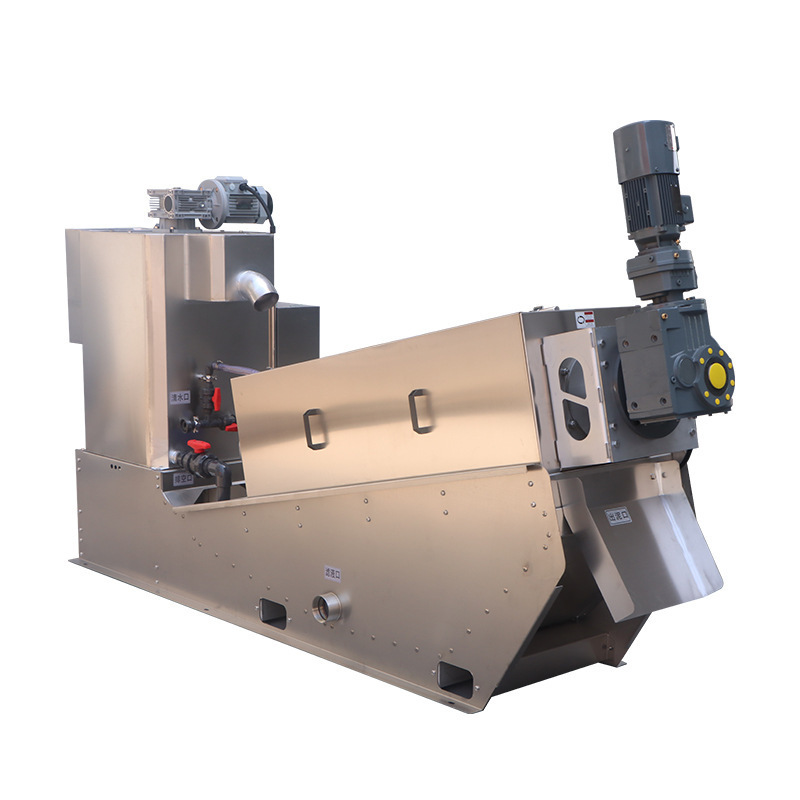

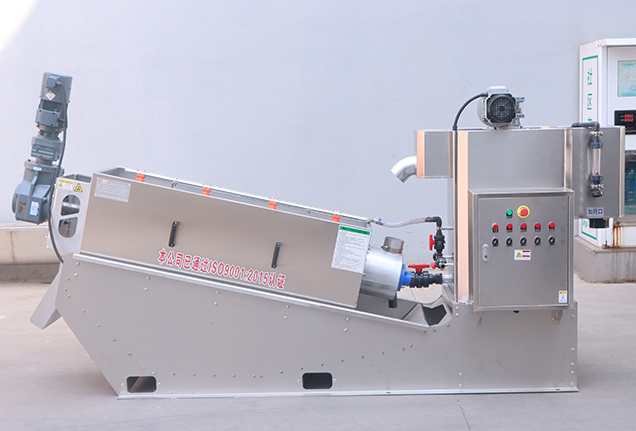

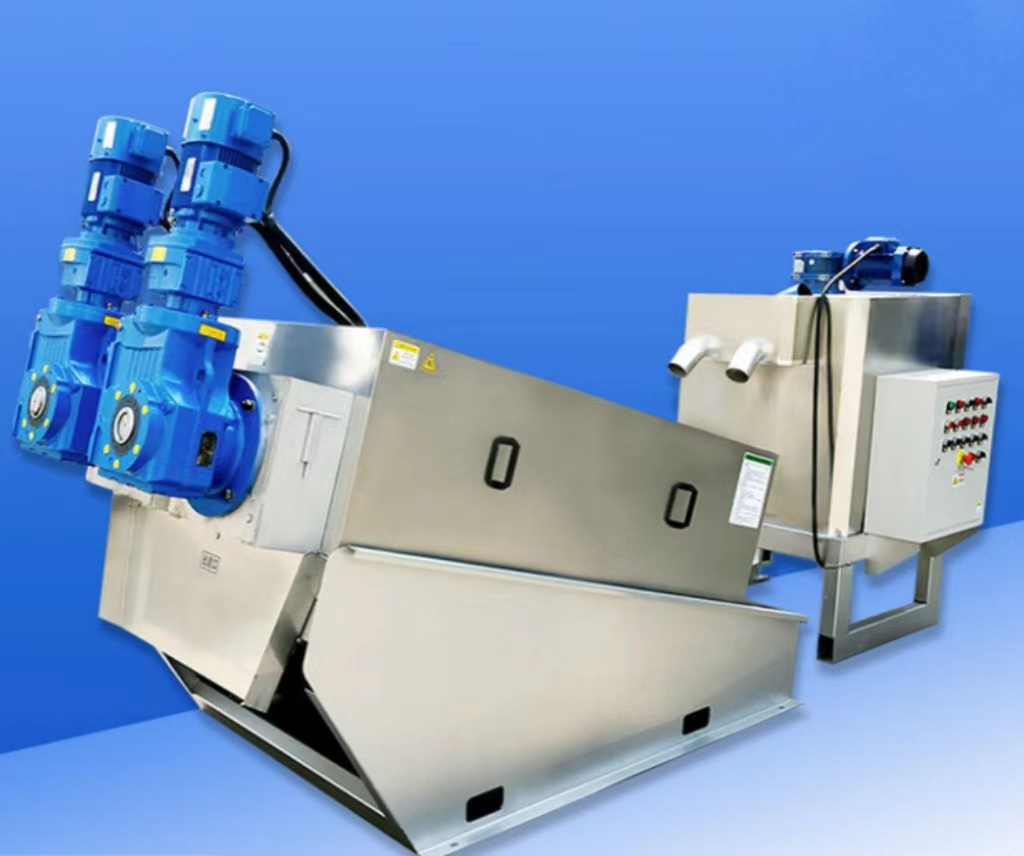

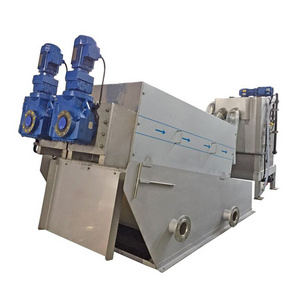

Sludge Separator

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Zhuoyu

-

Material:

-

wooden package

-

Weight:

-

500kg

-

Productivity:

-

30-70kg/h

-

Weight (KG):

-

500 kg

-

Product name:

-

Sludge Separator

Product Description

- The traditional sludae treatment reguired a lots of pre-treatment process before the dewatering of sludge begin With SDP, the dewatering process can now be processed a low concentrated sludge from Oxidation ditch ( aeration tank which provide the advantages in removing odor from sludge, reduce investment cost for Thickener tank and other related equipment as well as help in stabilizing the amount of phosphorus return into oxidation ditch which further implement a stable dewatering process.

Scope of application

advantage

Processing

- The dewatering process begin at the initial section called Thickening zone, when the screw shaft rotating and separating liquid from solid sludge by the gaps between the multi-disc rings. The filtrated will then be discharge at the bottom drain hole while sludge will moving on to Dewatering zone where the pitch of the screw and the gaps between the multi-rings decrease at the end of drum thus increasing internal pressure at the end plate to discharge dry sludge cake.

Product pictures

Packaging & Shipping

Our Services

Hot Searches