- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

MIKIM

-

Voltage:

-

380V50hz

-

Dimension(L*W*H):

-

1.6m*0.65m*1.4m

-

Weight:

-

300 KG

-

Features:

-

Charcoal Making Machine

-

Product name:

-

Sawdust Charcoal Machine

-

Keyword:

-

Biomass briquette machine

-

Raw Material:

-

Sawdust

-

Power:

-

5kw/18.5kw/22kw/30kw

-

Finished Products:

-

Charcoal/Sawdust/Biomass rods

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Application:

-

Barbecue (BBQ),Heating, Barbecue (BBQ),Heating

-

Production Capacity:

-

250-350kg/h, 250-350kg/h

-

Place of Origin:

-

China

-

Brand Name:

-

MIKIM

-

Voltage:

-

380V50hz

-

Dimension(L*W*H):

-

1.6m*0.65m*1.4m

-

Weight:

-

300 KG

-

Features:

-

Charcoal Making Machine

-

Product name:

-

Sawdust Charcoal Machine

-

Keyword:

-

Biomass briquette machine

-

Raw Material:

-

Sawdust

-

Power:

-

5kw/18.5kw/22kw/30kw

-

Finished Products:

-

Charcoal/Sawdust/Biomass rods

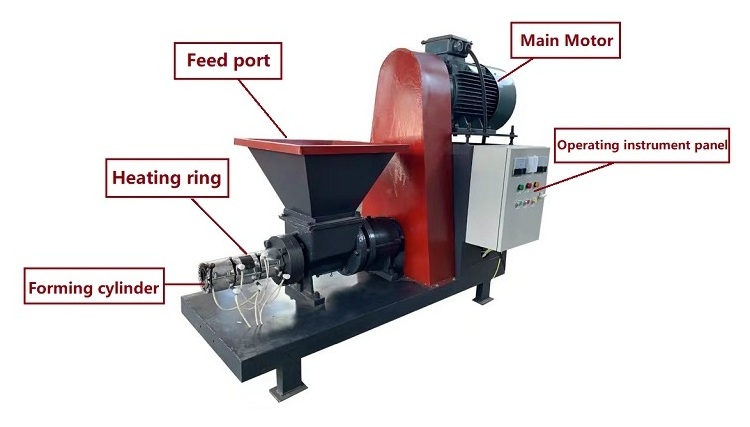

Product Description

Factory Compressed Wood Sawdust Biomass Tree Leaves Bamboo Charcoal Coal Briquettes Press Manufacturing Machines Price

The biomass briquette machine can be divided into 50 rod machine and 70 rod machine according to the size of the molding barrel. The bar making machine is a main equipment which is made of wood, rice hull, peanut shell, plant straw and other carbon containing wood materials (without adding any additives), and is made into rod solid fuel under high pressure and high temperature.

|

Model

|

Motor

|

Capacity

|

Dimension(m)

|

Weight

|

|

BR-50A

|

15kw

|

260-280kg/h

|

1.6*0.65*1.4

|

700kg

|

|

BR-50B

|

18.5kw

|

300-320kg/h

|

1.7*0.65*1.4

|

800kg

|

|

BR-50C

|

22kw

|

320-340kg/h

|

1.9*0.7*1.45

|

900kg

|

|

BR-80

|

22kw

|

250-300kg/h

|

1.8*0.7*1.6

|

700kg

|

Product Application

The process for sawdust briquetting press as follow:

1. Crush the raw material into small pieces (diameter is about 3-5mm)

2. Dry the material by machine or dried it in the sun , till the moisture is less than 12%

3. Put the material into feed let of briquette machine

4. Produce the briquette stick from biomass material without any additive

5. Carbonized the briquette stickFireplace etc.

2. Dry the material by machine or dried it in the sun , till the moisture is less than 12%

3. Put the material into feed let of briquette machine

4. Produce the briquette stick from biomass material without any additive

5. Carbonized the briquette stickFireplace etc.

Application for Charcoal Briquette :

1. Used as bio fuels for boiler

2. For Stove, Home heating

3. Used BBQ charcoal for Barbecue

4. Fuels for Europe country Fireplace etc.

Our Advantages

1. The machine has the characteristics of reasonable design, reliable manufacturing quality, simple structure, convenient

operation, small volume, less area, less work and electricity saving.

operation, small volume, less area, less work and electricity saving.

2. The designed automatic control electric heating device can adjust the dry humidity of the material randomly, ensure the stability of the material forming and improve the working efficiency.

3. The main parts of this product are specially treated with wear-resistant material, so it can be continuously pressed and durable.

4. It is suitable for the pressing and forming of various biomass raw materials, with less energy consumption and high production efficiency.

5. Three bearing the heart of the old machine is four, an increase of the machine stability and durability.

6. The old type of oil - based lubrication is oil immersion lubrication, as long as it is not short of oil, it can be used for many years.

7. Increase the pitch to increase the feed volume, thus greatly increase the output.

8. The structure of the molding cylinder is improved, the friction force between the machine and the raw material is reduced, and the density of the mandrel is increased.

Recommend Products

Packing

Hot Searches