* It is servo motor that is used for controlling two-way pump to reverse liquid flow, so as to make slide blocks lift and fall.

* Flow, pressure and direction of hydraulic oil are under the control of dual-driven oil pump and servo motor.

* Overflow will never happen while slide block works. No electric power is needed while waiting for next procedure. The strength of electricity saving stands out if long-term use.

- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

320 mm

-

Width of Working Table (mm):

-

250 mm

-

Dimension:

-

3200*1800*2500

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HSG

-

Weight (KG):

-

7000

-

Motor Power (kw):

-

7.5 kw

-

Marketing Type:

-

plate bending equipment

-

Product name:

-

sheet bending machines

-

Keyword:

-

hsg press brake

-

Function:

-

Bilateral Loading Intelligent High-speed Zoom Cutting Head

-

Cutting materials:

-

Metal CS SS Aloy Aluminum Brass Cropper

-

Max cutting speed:

-

80m/min

-

Fiber Laser Power:

-

3000W 4000W 5000W 6000W

-

Cooling system:

-

Water Cooling System

-

After-sales Service Provided:

-

1 Year Wrantty

-

Laser-type:

-

Fiber Laser

Quick Details

-

Machine Type:

-

Torsion Bar

-

Length of Working Table (mm):

-

3200

-

Slider Stroke (mm):

-

120 mm

-

Throat Depth (mm):

-

320 mm

-

Width of Working Table (mm):

-

250 mm

-

Dimension:

-

3200*1800*2500

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HSG

-

Weight (KG):

-

7000

-

Motor Power (kw):

-

7.5 kw

-

Marketing Type:

-

plate bending equipment

-

Product name:

-

sheet bending machines

-

Keyword:

-

hsg press brake

-

Function:

-

Bilateral Loading Intelligent High-speed Zoom Cutting Head

-

Cutting materials:

-

Metal CS SS Aloy Aluminum Brass Cropper

-

Max cutting speed:

-

80m/min

-

Fiber Laser Power:

-

3000W 4000W 5000W 6000W

-

Cooling system:

-

Water Cooling System

-

After-sales Service Provided:

-

1 Year Wrantty

-

Laser-type:

-

Fiber Laser

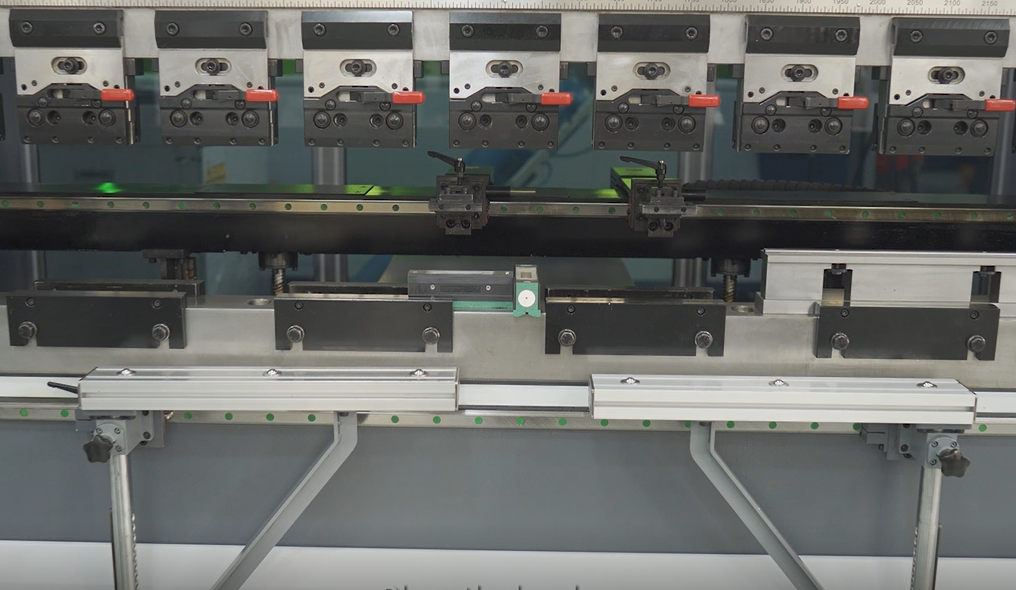

Customized Bending Press Brake Machine Sheet Automatic Electric Hydraulic Metal Steel Carbon Torsion Bar Competitive Price

Bending Machine

Advantage:

1.Two-way Convex Deflection Compensation

2.Various Upper and Lower Tools

3.Hydraulic Oil Consumption 76L

4.Optional Collaborative Robot

* Machine appearance, technical parameters, function description, data comparison shown in this page are from HSG in-house laboratory. All testing results and experimental data shall be subject to real machine.

Product Description

Energy-saving Technology

Its slide block, lower platform, left and right column are subject to finite element mechanical analysis. As thus, the overall bending precision will be kept within 0.5°.

Bending precision ≤ 0.5°

Italian ESA S650 Operating System

* 15-inch user-friendly touch screen

* Calculate bending force according to sheet length and thickness

* Database available for recording the correction of bending angle, with less time for that in future

* Accept sudden power failure and adapt to less desirable environment

Easy to Install and Operate, High Accuracy

Proficient skills unneeded while getting shapely bending, lower the professional threshold and labor costs;

Easy to install, firm and light, high operability;

German ELGO adopted, high bending accuracy guaranteed relying on micron-sized data, depth accuracy controlled as ±0.01mm.

Easy to install, firm and light, high operability;

German ELGO adopted, high bending accuracy guaranteed relying on micron-sized data, depth accuracy controlled as ±0.01mm.

Efficient and Reliable Post-positioning System

Position after high-speed moving, X-axis: 500 mm/s, Z-axis: 700 mm/s, R-axis: 60 mm/s; length measured on X-axis: 600 mm;

High positioning accuracy, X-axis: ±0.01 mm, Z-axis: ±0.1 mm, R-axis: ±0.1 mm.

Note: Only applicable to HB1003/HB6020.

High positioning accuracy, X-axis: ±0.01 mm, Z-axis: ±0.1 mm, R-axis: ±0.1 mm.

Note: Only applicable to HB1003/HB6020.

Further Expansion of Processing Range

Its open height and stroke of slide block are raised to 520mm and 250mm respectively. In combination with 420mm (depth) throat,

the bending range is further expanded. Time spent on taking out bending workpiece is reduced and any possible scratch is

prevented.

the bending range is further expanded. Time spent on taking out bending workpiece is reduced and any possible scratch is

prevented.

Open height 520mm

Depth of throat 420mm

Stroke of slide block 250mm

Post-positioning System

Backgauge can move at the speed of 1000mm/s. The slide block will lift and fall at the speed of 200mm/s. The bending speed reaches 15mm/s.

German COMAU Six-axis Collaborative Robot (Optional)

Automation interface is provided for upgrades anytime.

* Automatic sheet separation

* Automatic sheet stacking

* Automatic loading & unloading

* Automatic sheet rolling-over

* Automatic bending order change

* Automatic sheet separation

* Automatic sheet stacking

* Automatic loading & unloading

* Automatic sheet rolling-over

* Automatic bending order change

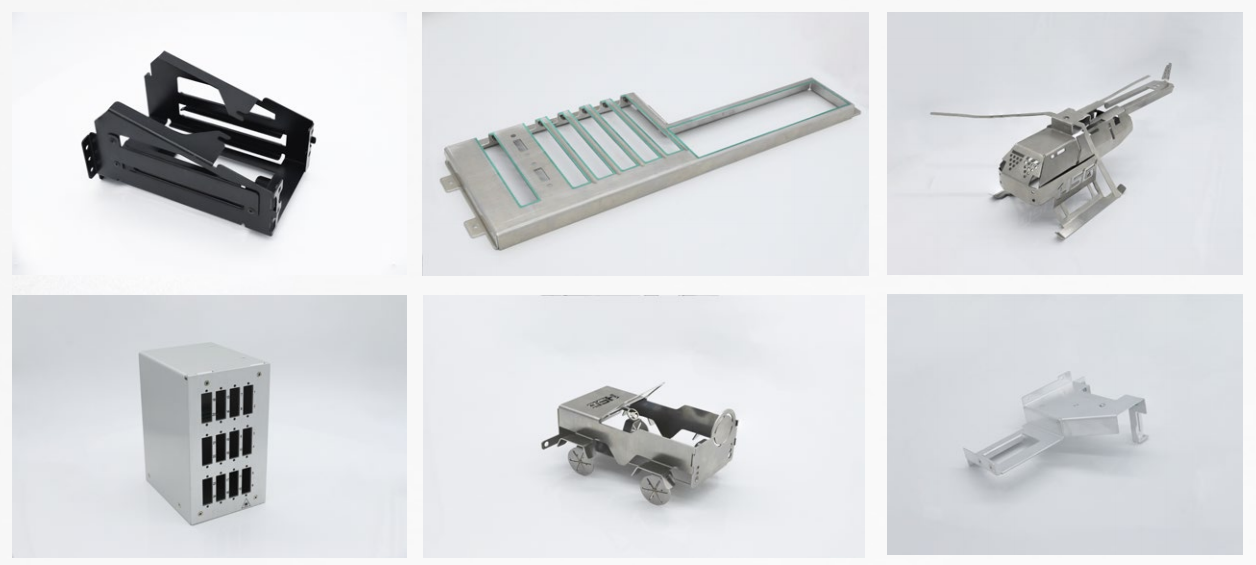

Sample Bending Display

Specification

|

Technical Parameters

|

HB6020

|

HB1003

|

HB2204

|

|

Bending Force

|

600KN

|

1000KN

|

2200KN

|

|

Bending Length

|

2150mm

|

3100mm

|

4300mm

|

|

Spacing of Side Plates

|

1700mm

|

2700mm

|

3760mm

|

|

Height of Lower Platform

|

950mm

|

950mm

|

950mm

|

|

Depth of Throat

|

420mm

|

420mm

|

420mm

|

|

Open Height

|

520mm

|

520mm

|

520mm

|

|

Fast Falling Speed of Y Axis

|

200mm/s

|

200mm/s

|

150mm/s

|

|

Bending Speed of Y Axis

|

15mm/s

|

15mm/s

|

12mm/s

|

|

Capacity of Oil Tank

|

76L

|

76L

|

76L

|

Hot Searches