- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Danny

-

Product name:

-

Carbide Flow Punch

-

Material:

-

tungsten carbide

-

Application:

-

Drilling Holes

-

Size:

-

M2 M3 M4 M5 M6 M8 M10 M12 M14 M16 M18 M20

-

Surface treatment:

-

heat treatment

-

Suitable for:

-

Steel, alloy steel, iron, steelless

-

Keyword:

-

Thermal Drill

-

Feature:

-

Durable

-

Advantage:

-

High precision

-

Tool Flute Type:

-

straight

Quick Details

-

Type:

-

Center Drill Bit, Core Drill Bit, Countersink Drill Bit, Gun Drill Bit, Indexable Drill Bit, Spade Drill Bit, Twist Drill Bit

-

Use:

-

Metal Drilling

-

Finish:

-

Black Oxide, ZINC, Plain, heat treatment

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Danny

-

Product name:

-

Carbide Flow Punch

-

Material:

-

tungsten carbide

-

Application:

-

Drilling Holes

-

Size:

-

M2 M3 M4 M5 M6 M8 M10 M12 M14 M16 M18 M20

-

Surface treatment:

-

heat treatment

-

Suitable for:

-

Steel, alloy steel, iron, steelless

-

Keyword:

-

Thermal Drill

-

Feature:

-

Durable

-

Advantage:

-

High precision

-

Tool Flute Type:

-

straight

Products Description

Made of durable steel material, more sturdy and long service life.

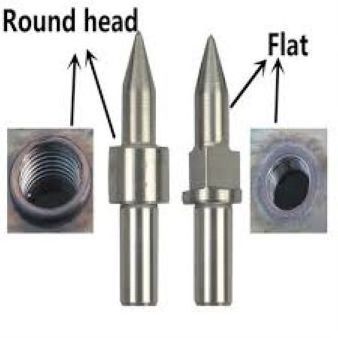

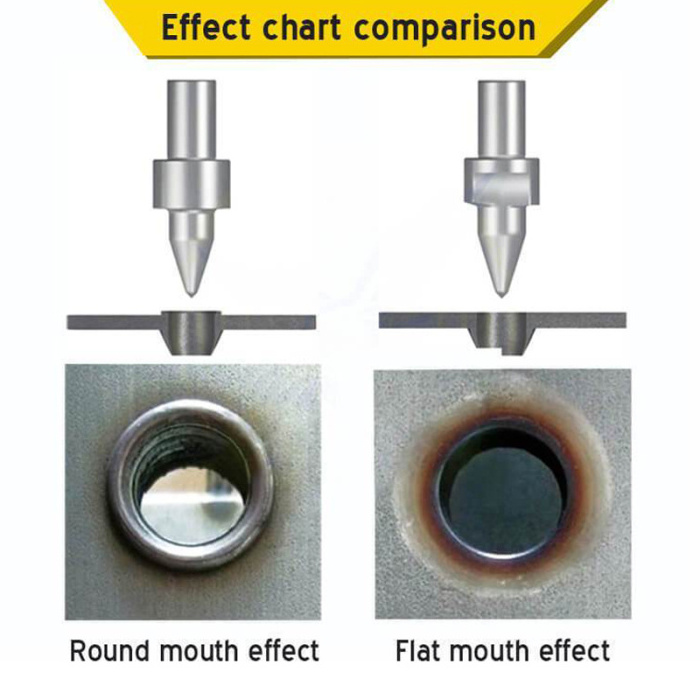

There are flat and round two types.

Round type frictiondrill (standard type frictiondrill): frictiondrill penetrate the workpiece while drawing the bushing to form a

convex ring.

The surface suitable for thread sealing or nut washer.

Flat type frictiondrill (designated flat frictiondrill): the middle part of the drill grinding step melt

and the hot melt drilling to penetrate the workpiece drawing to form a convex surface of the workpiece, make the surface smooth.

Wide range of applications, practical and energy efficient

There are flat and round two types.

Round type frictiondrill (standard type frictiondrill): frictiondrill penetrate the workpiece while drawing the bushing to form a

convex ring.

The surface suitable for thread sealing or nut washer.

Flat type frictiondrill (designated flat frictiondrill): the middle part of the drill grinding step melt

and the hot melt drilling to penetrate the workpiece drawing to form a convex surface of the workpiece, make the surface smooth.

Wide range of applications, practical and energy efficient

Details Images

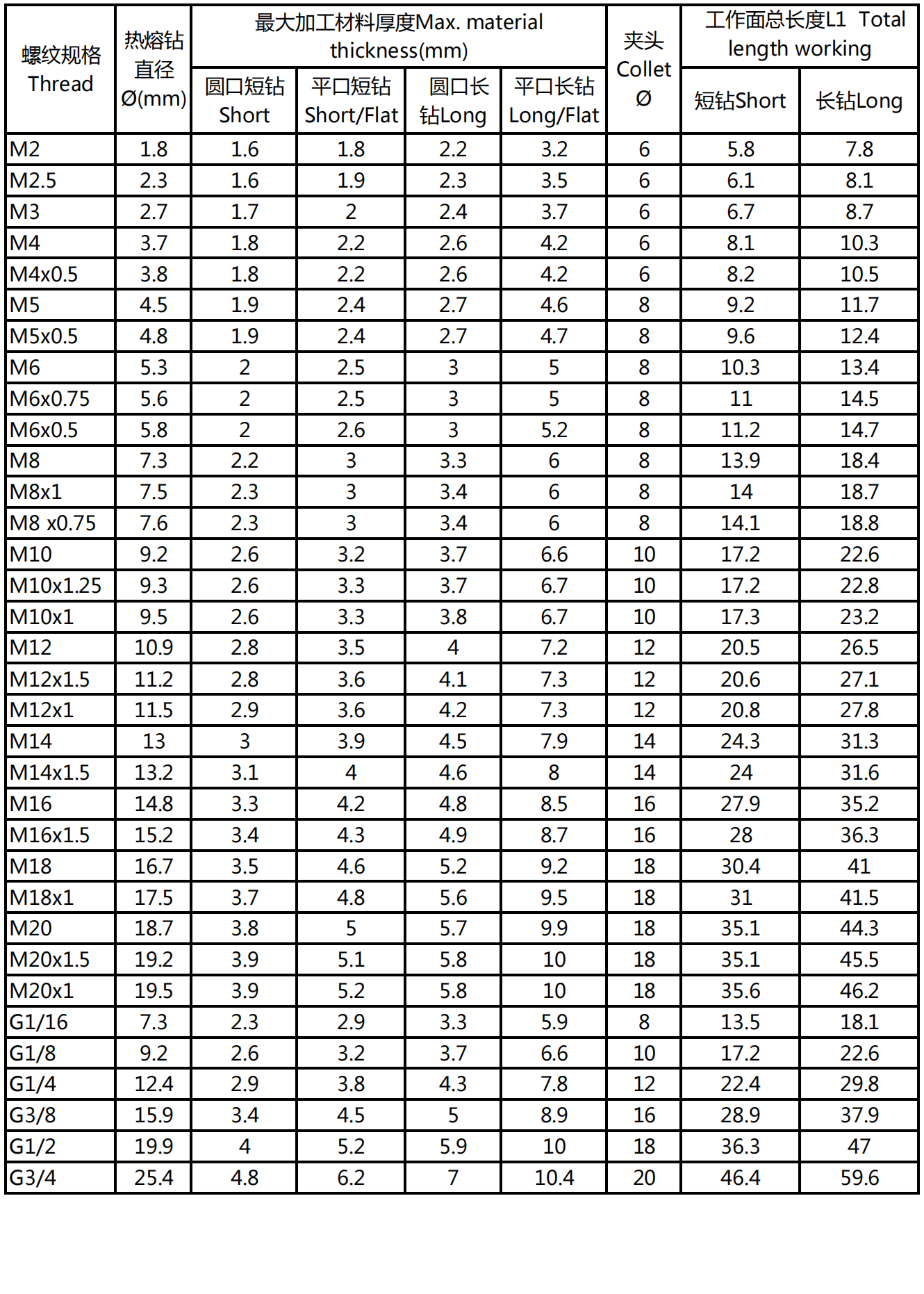

Specification

Item name: Drill bit

Type: Flat Type, Round Type

Color: Grey

Material: Steel

Size: M 3, M 4, M 5, M 6, M 8, M 10

Dimensions(approx): M3 (2.73mm) / M4 (3.7mm) / M5 (4.5mm) / M6 (5.3mm) / M8 (7.3mm) / M10 (9.2mm)/ M12 (10.9mm) / M14 (13mm)

Package included:

1 x Drill bit

Note:

1. Due to the light and screen difference, the item's color may be slightly different from the pictures.

2. Please allow 1-3cm differences due to manual measurement.

Type: Flat Type, Round Type

Color: Grey

Material: Steel

Size: M 3, M 4, M 5, M 6, M 8, M 10

Dimensions(approx): M3 (2.73mm) / M4 (3.7mm) / M5 (4.5mm) / M6 (5.3mm) / M8 (7.3mm) / M10 (9.2mm)/ M12 (10.9mm) / M14 (13mm)

Package included:

1 x Drill bit

Note:

1. Due to the light and screen difference, the item's color may be slightly different from the pictures.

2. Please allow 1-3cm differences due to manual measurement.

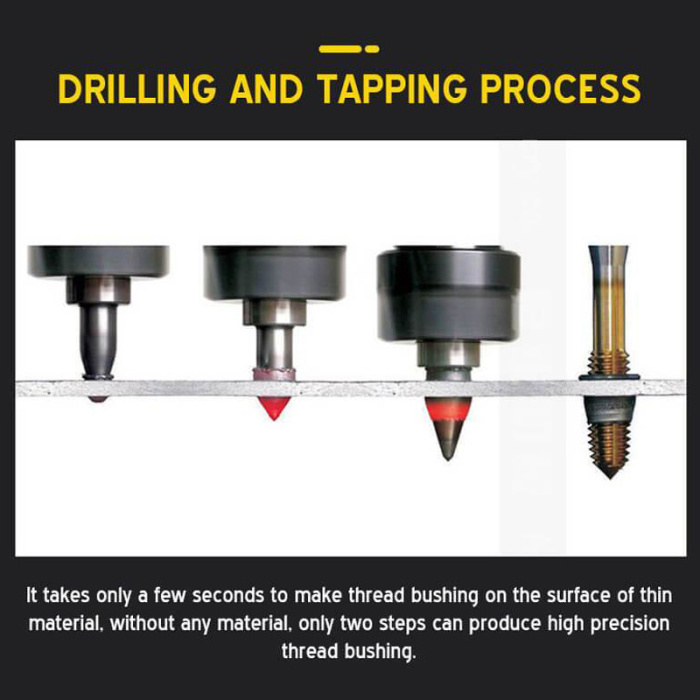

Recommended operating steps for hot melt drills

The following are the required equipment requirements and recommended correct operating steps and usage methods for hot melt drilling processing:

1. Correct selection of hot melt drill (aperture and type)

2. Choose the recommended power and speed

3. Use the recommended heat dissipation tool handle

4. Correctly screw the chuck into the locking nut of the heat dissipation knife handle and install it into the knife handle

5. Install the hot melt drill bit into the chuck and lock it tightly (regularly check and adjust the clamping force of the tool)

6. Connect the heat dissipation tool handle to the drilling machine

7. Tighten the processed workpiece on the workbench

8. Ensure a suitable operating range between the workpiece and the hot melt drill (set the starting and ending positions correctly)

9. Correct selection of speed

10. Correct selection of drilling depth

11. Select the recommended feed rate based on material and thickness

12. When using a new drill bit for the first time, add a small amount of hot melt paste to the drill bit

13. Press both handles down simultaneously with both hands to maintain a regular and uniform feed rate without pausing

When the bottom of the hot melt drill bit reaches the surface of the workpiece, gently and quickly release the handle

15. Pay attention to the drilling time and drill bit color (when operating correctly, the hot melt drill bit is dark red, and the color is bright red or yellow, indicating that the hot melt drill bit is overheating)

16. Pay attention to adjusting the speed, feed depth, and feed speed (steps 9, 10, and 11). Excessive temperature: Reduce the speed or increase the feed rate, or both

17. Attention:

1、 When using a new drill bit for the first time, add a small amount of hot melt paste to the rotating hot melt drill bit; After drilling each hole, add a small amount of hot melt paste to the rotating hot melt drill bit and maintain 10 holes.

2、 Afterwards, after drilling 2-3 holes, add a small amount of hot melt paste to the rotating hot melt drill bit.

3、 Before each tapping, add a small amount of tapping oil to the rotating extrusion tap.

18. Operation of flat mouth hot melt drill bits:

During the operation of the flat end drill bit, only an instant acceleration feed is required at the beginning of the cutting. Instantaneous acceleration of feed will greatly extend the service life of the drill bit. By observing the length and shape of the drilling chips, the accuracy of the operation can be determined.

Hot Searches