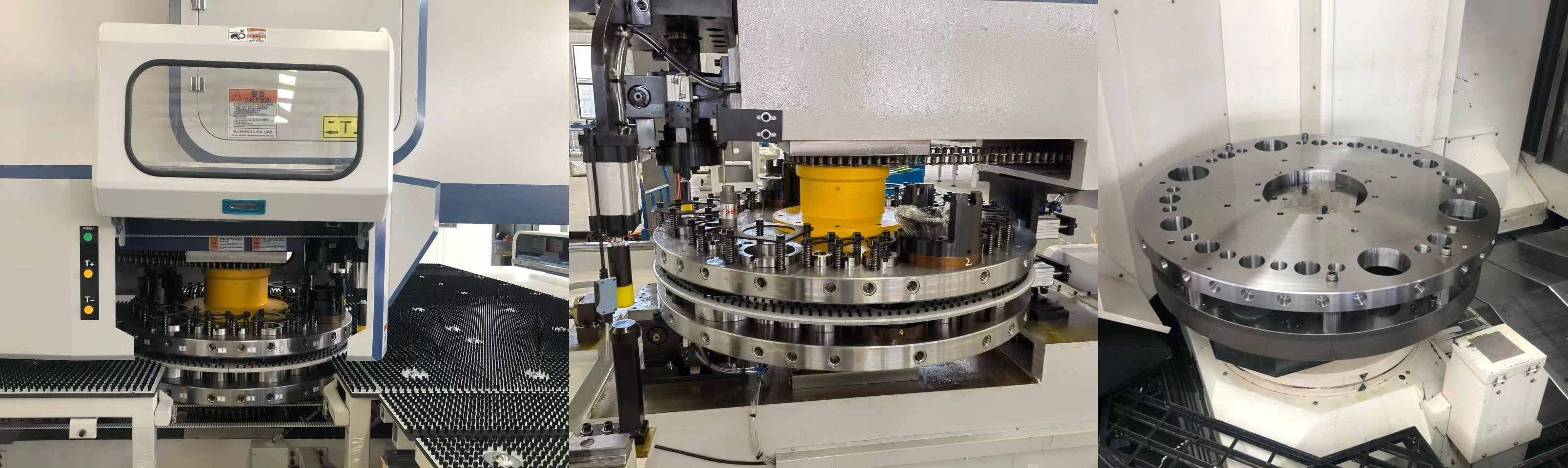

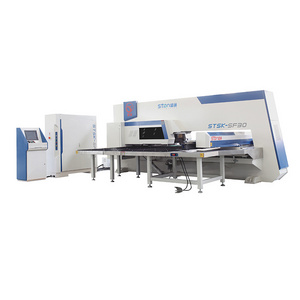

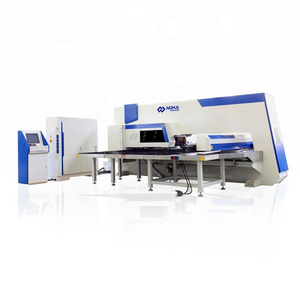

·ADVANCED STRUCTURE

Equipped with advanced combat head structure, reasonable lubrication sealing structure,

good

static and dynamic response characteristics, little impaction of temperature change with environmental interference.

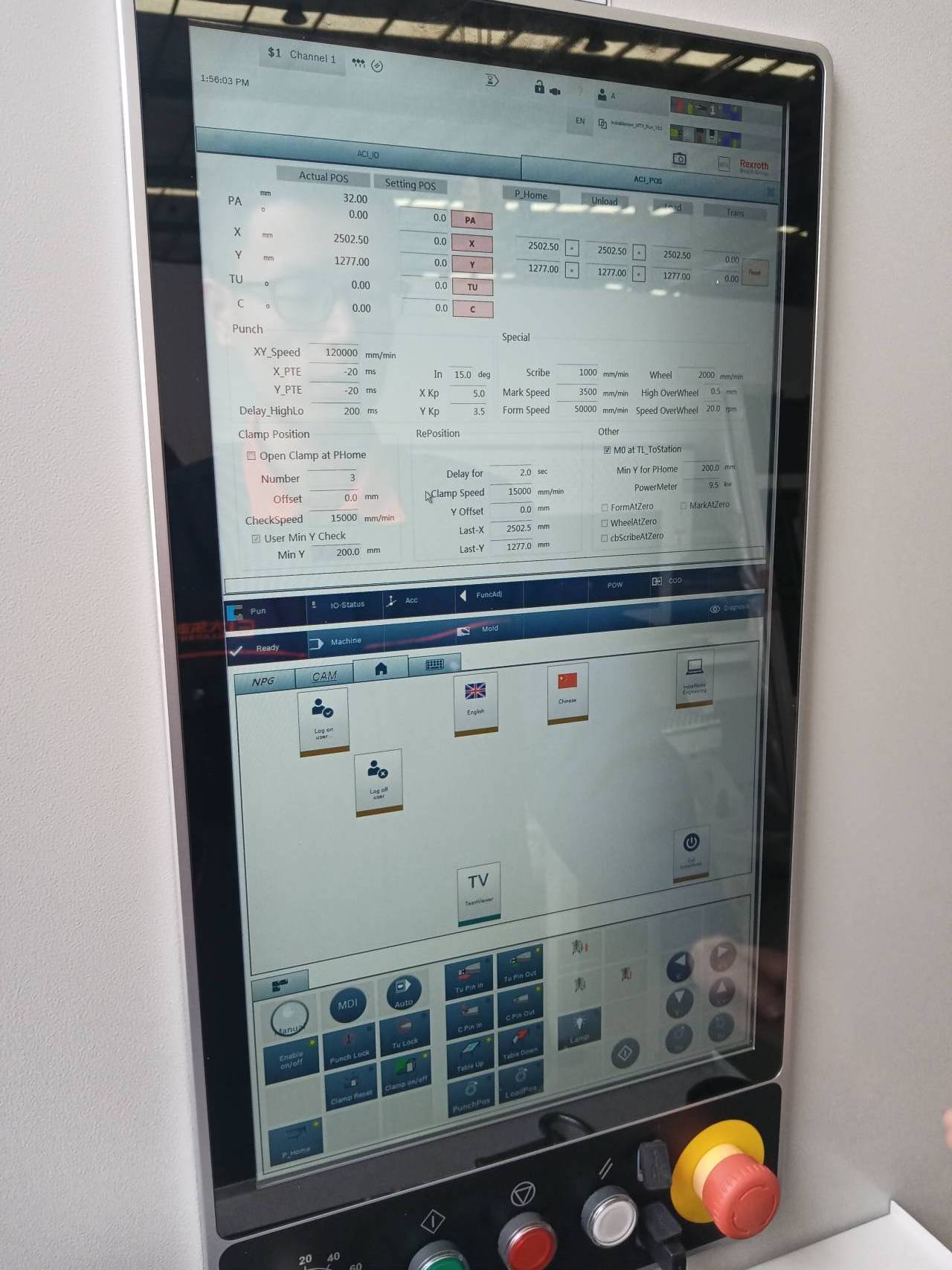

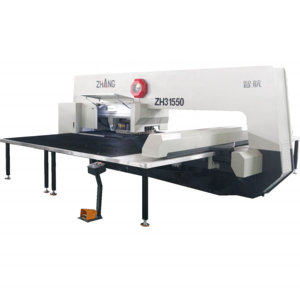

·STROKE, SPEED ADJUSTABLE

Automatically select punching stroke for different thickness to improve processing efficiency. I

n each point of every single mode on the trip, stamping speed is adjustable.

·HIGH PRECISION & LONGER LIFE

With high rigidity and paired processing turntable, station hole, positioning hole location accuracy is

ensured

. High concentricity upper and lower dies greatly extend the life of the mold.