- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 year

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

CYKY

-

Model Number:

-

CYKY-1202

-

Type:

-

SAW BLADE

-

Blade Material:

-

diamond

-

Product Name:

-

Precision Diamond Wire Saw

-

Power Supply:

-

AC 220 V, 50/60 Hz

-

Frame Material:

-

Heavy-duty Aluminum alloy

-

Travel Distance (Z):

-

0.01 - 300mm (±0.01mm)

-

Stage Rotation (R):

-

0.01 - 360 degree (+/-0.032 degree)

-

Spooler Rotating Speed:

-

0 - 5 meter/second

Quick Details

-

Blade Length:

-

6in, 10in

-

Finishing:

-

Other

-

Size:

-

1500*1200*800mm, 48"x40"x72"

-

Warranty:

-

1 year

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

CYKY

-

Model Number:

-

CYKY-1202

-

Type:

-

SAW BLADE

-

Blade Material:

-

diamond

-

Product Name:

-

Precision Diamond Wire Saw

-

Power Supply:

-

AC 220 V, 50/60 Hz

-

Frame Material:

-

Heavy-duty Aluminum alloy

-

Travel Distance (Z):

-

0.01 - 300mm (±0.01mm)

-

Stage Rotation (R):

-

0.01 - 360 degree (+/-0.032 degree)

-

Spooler Rotating Speed:

-

0 - 5 meter/second

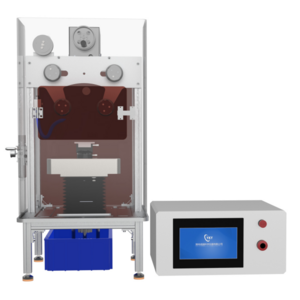

Precision Diamond Wire Saw with Sample Stage ,Diamond Cutting wire machine

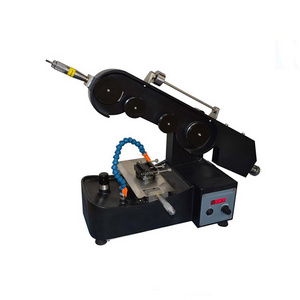

The CYKY-1202 precision reciprocating type diamond wire saw uses diamond impregnated wire (0.3mm dia.) for cutting all kinds of materials (especially for larger size crystals, such as Si, Ge, and GaAs, etc. with boule diameter up to 12" (300 mm) and leaves a smooth cutting surface. Y and Z axis and the rotary sample stage are all driven by the stepper motors which provide the precise, stable and varied cutting of the samples. The cutting program can be set in the touch screen controller which includes the feeding speed, cutting depth, width, slice number, etc.

Product details

|

Power Supply |

AC 220 V, 50/60 Hz, 350W (110V available upon request) |

|

Frame Material |

Heavy-duty Aluminum alloy |

|

Controller |

6" color LCD touch screen control panel

|

|

Three axles Sample Stage

|

|

|

Travel Distance (Z) |

0.01 - 300mm (±0.01mm) |

|

Feeding Speed (Z up) |

0.01 - 30 mm/min (±0.01mm)

|

|

Back Speed (Z down) |

1 - 30mm/min (±0.01mm)

|

|

Travel Distance (Y) |

0.01 - 300mm (±0.01mm)

|

|

Cutting Width (Y) |

0.01 - 300mm (±0.01mm)

|

|

Stage Rotation (R) |

0.01 - 360 degree (+/-0.032 degree) |

|

Spooler Rotating Speed |

0 - 5 meter/second |

|

Diamond wire |

Ø 0.35mm x 150m Length (accuracy +/- 0.03mm) |

|

Maximum Sample Dimensions |

Ø300mm×300mm |

|

Wire Tension System |

|

|

Cooling System |

One Coolant tank and two small immersion pumps are included for cooling and lubricating diamond wire ( only use anti-rust liquid and oil as a coolant, never use water ) |

|

Optional |

|

|

Overall Dimension ( L×W×H ) |

Wire saw: 1100mm×892mm×1700mm

|

|

Warranty |

One year limited, not including diamond wire and rusted parts |

Pciture showed: