- Product Details

- {{item.text}}

Quick Details

-

Max. Spindle Speed (r.p.m):

-

2000 r.p.m

-

Spindle Bore(mm):

-

300

-

Width of bed (mm):

-

450 mm

-

Spindle Motor Power(kW):

-

15/18.5

-

Travel (X Axis)(mm):

-

300 mm

-

Travel (Z Axis)(mm):

-

450 mm

-

Place of Origin:

-

Zhejiang, China

-

Dimension(L*W*H):

-

2260*1780*2800

-

Brand Name:

-

OEM

-

Model Number:

-

SVB650

-

Voltage:

-

-

-

Weight (KG):

-

2000

-

Marketing Type:

-

New Product 2023

-

Worktable size:

-

700*400mm

-

T -slot(N-W*D):

-

5*18*100mm

-

X axis travel:

-

500mm

-

Y axis travel:

-

400mm

-

Z axis travel:

-

451mm

-

L*W*H:

-

2100*2300*2750mm

-

Max. load bearing of worktable:

-

300kg

-

Machine weight:

-

3900kg

Quick Details

-

Type:

-

VERTICAL

-

Max. Length of Workpiece (mm):

-

600

-

Year:

-

2023

-

Max. Spindle Speed (r.p.m):

-

2000 r.p.m

-

Spindle Bore(mm):

-

300

-

Width of bed (mm):

-

450 mm

-

Spindle Motor Power(kW):

-

15/18.5

-

Travel (X Axis)(mm):

-

300 mm

-

Travel (Z Axis)(mm):

-

450 mm

-

Place of Origin:

-

Zhejiang, China

-

Dimension(L*W*H):

-

2260*1780*2800

-

Brand Name:

-

OEM

-

Model Number:

-

SVB650

-

Voltage:

-

-

-

Weight (KG):

-

2000

-

Marketing Type:

-

New Product 2023

-

Worktable size:

-

700*400mm

-

T -slot(N-W*D):

-

5*18*100mm

-

X axis travel:

-

500mm

-

Y axis travel:

-

400mm

-

Z axis travel:

-

451mm

-

L*W*H:

-

2100*2300*2750mm

-

Max. load bearing of worktable:

-

300kg

-

Machine weight:

-

3900kg

Products Description

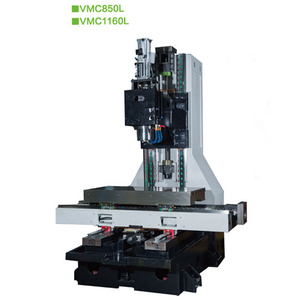

SVB500 small size high rigidity 3 axis cnc milling machine

The SVB500 vertical machining center adopts a vertical frame layout, with columns fixed on the bed. The spindle box moves up and down along the columns (Z-direction), the slide seat moves longitudinally along the bed (Y-direction), and the workbench moves laterally along the slide seat (X-direction). All three axes use linear guides, replacing sliding friction with rolling friction, which makes the movement speed faster and meets the requirements of high speed and precision. The three-axis adopts rolling track and large span design, ensuring long-lasting accuracy. X. The Y and Z-axis servo motors are directly connected to high-precision ball screws through gapless elastic couplings, reducing intermediate links and achieving gapless transmission. Each axis is equipped with imported precision angular contact screw special bearings for paired installation, and the ball screws are precisely pre stretched, with flexible feeding, accurate positioning, and high transmission accuracy.

|

Item

|

Unit

|

SVB500

|

SVB650

|

VMC1100L

|

VMC1200L

|

|||||

|

Worktable

|

|

|

|

|

|

|||||

|

Worktable size

|

mm

|

700*400

|

850*400

|

650*1300

|

700*1400

|

|||||

|

T-slot (N×W×D)

|

mm

|

5x18x100

|

5x18x100

|

5x18x100

|

5*18*115

|

|||||

|

Travel

|

|

|

|

|

|

|||||

|

Axis travel (X/Y/Z)

|

mm

|

500/400/500

|

650/400/500

|

100/650/700

|

1200/700/700

|

|||||

|

Machining range

|

|

|

|

|

|

|||||

|

Distance from spindle center to column front

|

mm

|

451

|

451

|

775

|

775

|

|||||

|

Distance from spindle end to work table

|

mm

|

100-600

|

100-600

|

150-850

|

103-803

|

|||||

|

Machine dimension

|

|

|

|

|

|

|||||

|

L×W×H

|

mm

|

2100*2300*2750

|

2100*2300*2750

|

4530*2880*3250

|

4830*2880-3250

|

|||||

|

Machine weight

|

|

|

|

|

|

|||||

|

Max. load bearing of worktable

|

kg

|

300

|

350

|

1000

|

1000

|

|||||

|

Machine weight

|

kg

|

3900

|

4100

|

9000

|

10000

|

|||||

|

Spindle

|

|

|

|

|

|

|||||

|

Spindle hole taper

|

|

BT40

|

BT40

|

BT40

|

BT50

|

|||||

|

Spindle power

|

Kw

|

5.5/7.5

|

7.5/11

|

11/15

|

11/15

|

|||||

|

Max. spindle speed

|

rpm

|

8000/10000

|

8000/10000

|

8000

|

6000

|

|||||

|

Feed(direct drive)

|

|

|

|

|

|

|||||

|

Max. feed speed

|

mm/min

|

10000

|

10000

|

10000

|

8000

|

|||||

|

Rapid feed speed (X/Y/Z)

|

m/min

|

48/48/32

|

48/48/32

|

24/24/15

|

24/24/15

|

|||||

|

Ball screw (diameter + lead)

|

|

|

|

|

|

|||||

|

Axis ball screw (X/Y/Z)

|

mm

|

3216/3216/3216

|

3216/3216/3216

|

4012/4012/4012

|

4012/4012/4012

|

|||||

|

Tool Magazine

|

|

|

|

|

|

|||||

|

Tool magazine capacity

|

T

|

16

|

16

|

24

|

24

|

|||||

|

Tool change time(T-T)

|

s

|

2

|

2

|

2.5

|

3

|

|||||

|

Positioning accuracy (National standard)

|

|

|

|

|

|

|||||

|

Positioning accuracy (X/Y/Z)

|

mm

|

0.008

|

0.008

|

0.010

|

0.010

|

|||||

|

Re-positioning accuracy(X/Y/Z)

|

mm

|

0.005

|

0.005

|

0.005

|

0.005

|

|||||

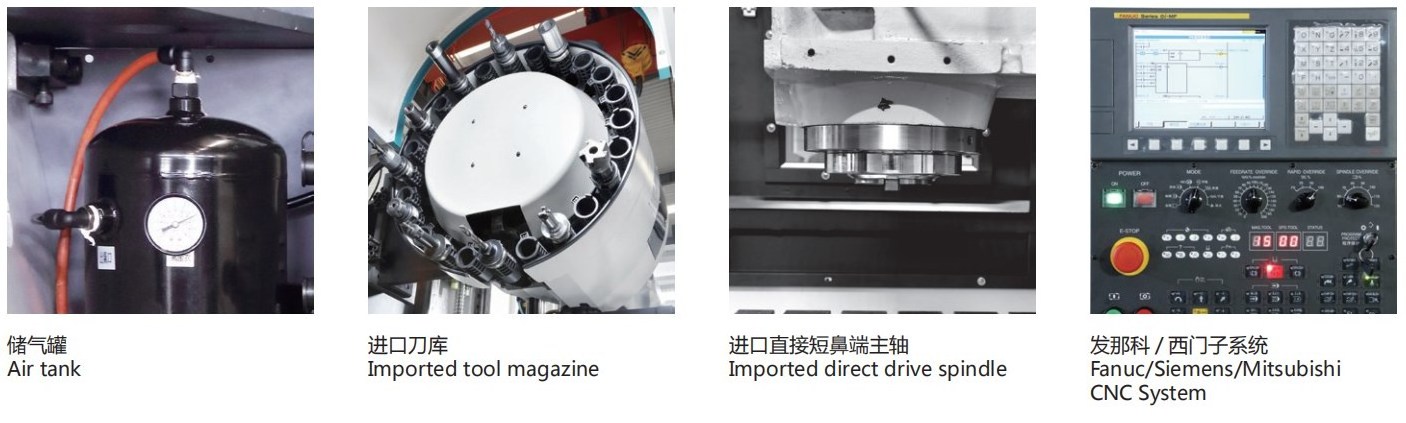

Machine structure :

---The contact ratio between spindle case and column increased to ensure spindle rigidity.

---1100mm wide machine body span and optimum supporting design can meet with fast feed of X and Y axis.

---Big size of “pyramid” column and with closed inner cavity to ensure low center but high rigidity support of Z axis.

---1100mm wide machine body span and optimum supporting design can meet with fast feed of X and Y axis.

---Big size of “pyramid” column and with closed inner cavity to ensure low center but high rigidity support of Z axis.

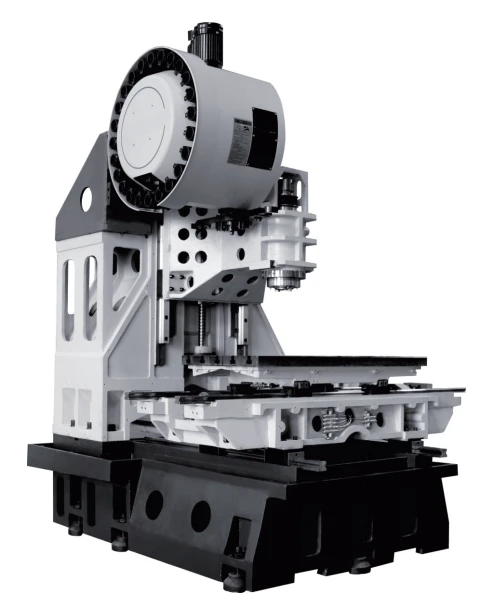

Preloaded and double anchored ball screw :

---Servo motor directly coupled ball screw.

---All the ball screws, linear guideway, bearings are well lubricated in time and ration.

---Y/Z axis adopt 45mm linear guideway while X axis adopts 35mm which make the rapid feed speed reach 48/48/32m/min.

---In order to eliminate thermal growth and increase accuracy, all axes are driven by high precision double anchored ballscrews. Also 5 rank high precision angular contacted bearing installed aside the ball screw and make pre-tension.

---All the ball screws, linear guideway, bearings are well lubricated in time and ration.

---Y/Z axis adopt 45mm linear guideway while X axis adopts 35mm which make the rapid feed speed reach 48/48/32m/min.

---In order to eliminate thermal growth and increase accuracy, all axes are driven by high precision double anchored ballscrews. Also 5 rank high precision angular contacted bearing installed aside the ball screw and make pre-tension.

Shoulder carrying tool magazine :

Shoulder carrying tool magazine can ensure Z axis geometric accuracy and perfect stability, rigidity and the minimum deformation when column loaded with tool magazine weight.

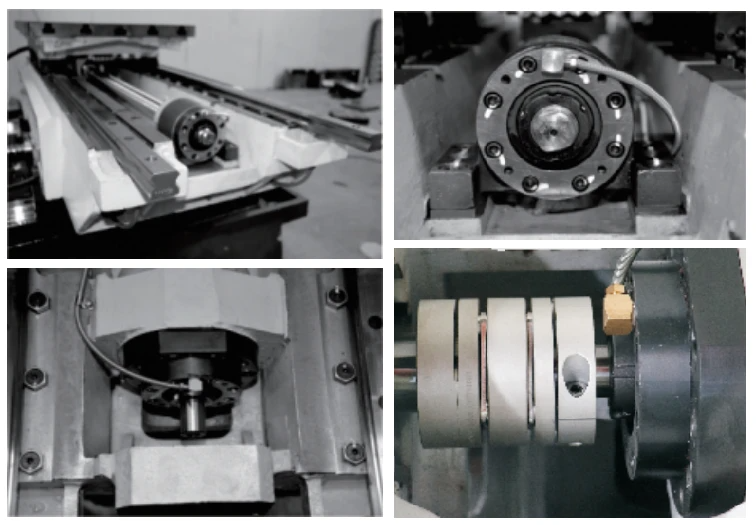

Large flow coolant fluid :

---Labyrinth style cover design to protect machine from scraps and cutting fluid.

----Standard equipped with inner side flushing system to remove scraps efficiently.

----Standard equipped with inner side flushing system to remove scraps efficiently.

Application

Related Products

CNC machines

*CNC worm grinding machine

*CNC forming gear grinding machine

*CNC rolling cutter shovel grinding machine

*CNC cutting edge grinder

*CNC grinding wheel repair machine

*CNC shovel tooth lathe

*Fully CNC high-speed gear hobbing machine

Processing tools

*

Measuring instruments

*

Production equipment

*

Gear hob

*

Insert gear hob

*

Gear hob

*

Worm gear hob

*

Involute spline hob

*

Triangular spline hob rectangular spline hob

*

Sprocket roller cutter

*

Circular arc gear hob

*

Synchronous belt roller cutter

Hot Searches