PE threading pipe is a high-tech product formed by extrusion using high-quality high-density polyethylene resin as the main raw material, with appropriate additives added. This product has the characteristics of corrosion resistance, aging resistance, impact resistance, high mechanical strength, long service life, and excellent electrical insulation performance.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sevenstars

-

Voltage:

-

380V 50HZ or customizable

-

Dimension(L*W*H):

-

13000*2000*3000mm

-

Power (kW):

-

60

-

Weight:

-

5000 KG

-

Name:

-

PE/HDPE Threading pipe

-

Raw material:

-

PE/HDPE resin

-

Final product:

-

Threading pipe

-

Type:

-

Single screw extruder

-

Color:

-

customizable

-

Inverter:

-

ABB Frequency Controller

-

L/D:

-

30:1

-

Capacity:

-

40-80kg/h

-

Pipe diameter:

-

16-32mm

-

Certification:

-

CE

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

30:1

-

Screw Speed (rpm):

-

25 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sevenstars

-

Voltage:

-

380V 50HZ or customizable

-

Dimension(L*W*H):

-

13000*2000*3000mm

-

Power (kW):

-

60

-

Weight:

-

5000 KG

-

Name:

-

PE/HDPE Threading pipe

-

Raw material:

-

PE/HDPE resin

-

Final product:

-

Threading pipe

-

Type:

-

Single screw extruder

-

Color:

-

customizable

-

Inverter:

-

ABB Frequency Controller

-

L/D:

-

30:1

-

Capacity:

-

40-80kg/h

-

Pipe diameter:

-

16-32mm

-

Certification:

-

CE

Product Description

PE/HDPE threading pipes

Application area

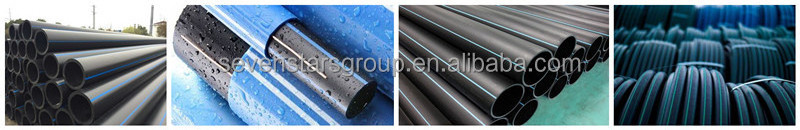

Widely used in urban road construction, community development, garden landscape, enterprise construction and other places, as a conduit for power, street lights, lawn lights, courtyard lights, community intelligence, cable TV, communication, intelligent transportation and other cables.

Product Features

1. Excellent physical properties are produced using high-quality polyethylene raw materials. It has good rigidity, strength, and flexibility. It is beneficial for the installation of pipelines.

2. Corrosion resistance and long service life. In coastal areas, the groundwater level is relatively high and the land humidity is high. The use of metal or other pipelines must be corrosion-resistant, and their lifespan is generally only 30 years. PE resistant pipes can withstand various chemical media and are not affected by soil corrosion.

3. PE pipe with good toughness and deflection is a high toughness pipe with a fracture elongation rate exceeding 500%. Strong adaptability to uneven ground settlement and misalignment of the foundation. Good seismic resistance. Small diameter pipes can be bent arbitrarily.

4. The pipe wall is smooth, with low friction coefficient, easy cable laying, and high construction efficiency.

5. Good electrical insulation performance, long service life (over 50 years for buried pipes), durable, and safe and reliable line operation.

6. Lightweight, easy to repair, install, and maintain, easy to transport and operate.

7. Small diameter pipes can be in the form of coils, with long pipe sections, fewer joints, and easy installation.

8. The pipes can be made into multiple colors for differentiation.

9. Excellent low-temperature impact resistance. PE has an extremely low low-temperature embrittlement temperature and can be safely used within the temperature range of 20-40. During winter construction, due to the good impact resistance of materials, there will be no occurrence of pipe brittle cracking.

10. Compared with other metal pipes, PE pipes have good wear resistance. The wear resistance is four times that of metal pipes.

11. Various new construction methods. In addition to the traditional excavation method, PE pipes can also be constructed using various new non excavation techniques, such as pipe jacking, lining, and cracking. This is a good choice for places where excavation is not allowed.

Detail Description

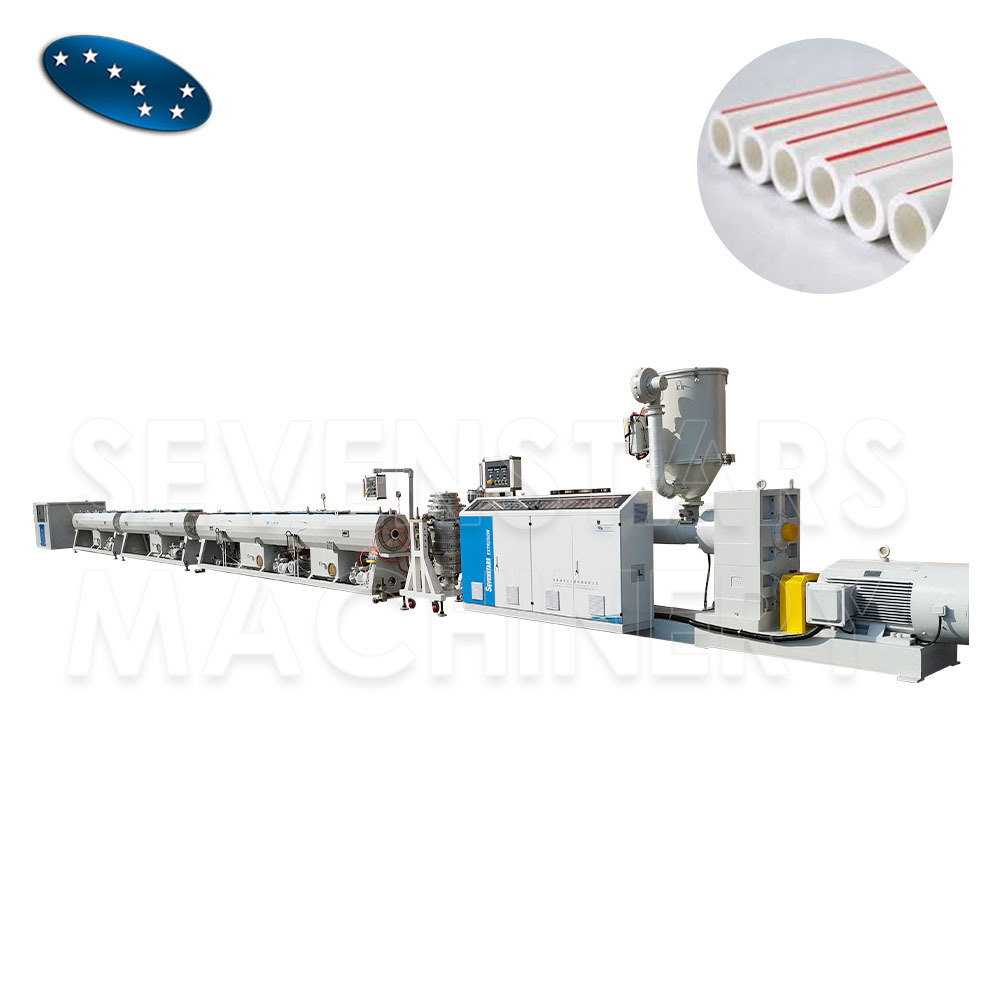

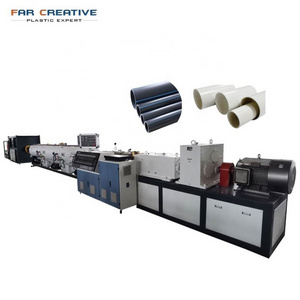

SJ45/30 Single screw extrusion line

Mould

Vacuum Calibration and cooling tank

Hauling off Machine

Laser printer

Cutting machine

Automatic double disc winder

Parameters

|

No

|

Name

|

Model

|

|

1

|

Vacuum feeding machine

|

ZJ200

|

|

2

|

Hopper dryer

|

STG-U75

|

|

3

|

Single-Screw Extruder

|

SJ45/30

|

|

4

|

Mould for PE pipe

|

/

|

|

5

|

Vacuum calibration and cooling chamber

|

/

|

|

6

|

Two claw hauling machine

|

/

|

|

7

|

Laser printer

|

/

|

|

8

|

Automatic dusty free cutter

|

/

|

|

9

|

Automatic double disc winder

|

/

|

Packing & Delivery

sea worthy packaging for

PE/PP/ABS rolling tube core extrusion production line

Hot Searches