65/33 Single screw extruder

Screw diameter: 65mm

L/D Ratio: 33:1

Screw&barrel material: 38CrMoAlA

Motor: 45kw

Frequency inverter :DELTA

Barrel heating method:Cast-alumium heating, with stainless steel protection

Output:130-200 kg/h

Temperature Control: Ormon

Contactor: Dexili

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

FOSITA

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

10m*1.5*1.2m

-

Power (kW):

-

11

-

Weight:

-

1500 KG

-

Type:

-

single wall corrugated pipe

-

Usage:

-

Water Pipe

-

Speed:

-

20-25m/min

-

Cooling method:

-

water cooling

-

Automatic Grade:

-

Automatic

-

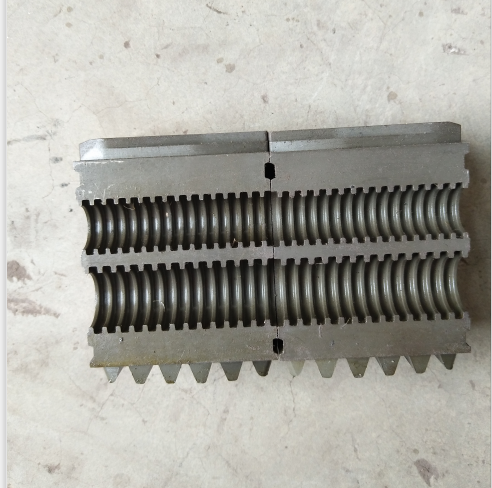

Mold number:

-

72 pairs

-

Mold material:

-

Nitriding treatment

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

28:1

-

Screw Speed (rpm):

-

1440 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

FOSITA

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

10m*1.5*1.2m

-

Power (kW):

-

11

-

Weight:

-

1500 KG

-

Type:

-

single wall corrugated pipe

-

Usage:

-

Water Pipe

-

Speed:

-

20-25m/min

-

Cooling method:

-

water cooling

-

Automatic Grade:

-

Automatic

-

Mold number:

-

72 pairs

-

Mold material:

-

Nitriding treatment

-

Marketing Type:

-

Ordinary Product

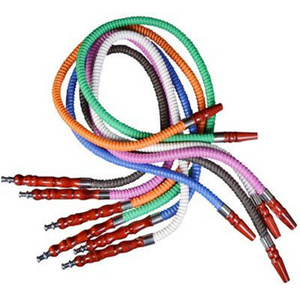

Product Application

The line shall be used to produce small diameterr single wall corrugated pipe in PE/PVC and PP raw material.Molding corrugated pipe with smooth inside and outside surface,and even ripple at one time by corresponding die.Used as electricity pipe,washing machine drain pipe,dust collector pipe and ventiduct,etc.

Technical Parameter

|

Pipe Line Model

|

Diameter Range(mm)

|

Extruder Model

|

Max Output(kg/h)

|

Max Machine Speed(m/min)

|

Main motor power(kw)

|

Line Length(m)

|

|

FST-16

|

Φ5-Φ16

|

SJ45

|

50

|

25

|

22

|

10

|

|

FST-50

|

Φ16-Φ50

|

SJ65

|

100

|

25

|

37

|

10

|

Characteristic

1.High cost performance and long life

2.High stability and precision performance

3.High automation degree

4.High production efficiency

5.Good after-sales servic

e

corrugated pipe forming machine(High speed)

Motor: 3kw

Frequency inverter: ABB

Production speed:20-25m/min

Quantity of shaping mold:72 pairs per set

Cooling method:Water cooling

Double Winder

Inner diameter of coil(mm):can be made as your request

Outside diamter of coil(mm):can be made as your request

Working method: pneumatic

a.After being informed machines ready for inspection, customer can send engineers to our factory.

b.After the machines are delivered to customer's factory;We will send one or two technicians to the factory after preparation work is completed;Technicians will be responsible for guide on-site installation and testing machines.

c.Meanwhile technicians will give free training lessons to labors in customer's factory.