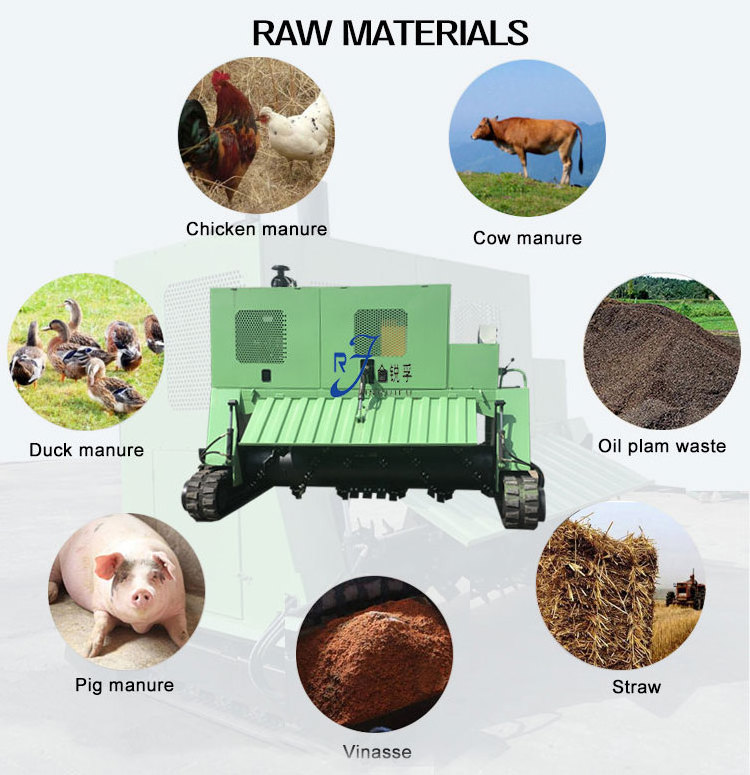

➽1. Agricultural waste: straw, dregs of beans, cotton dregs, rice bran, etc.➽2. Animal manure: mixture of poultry litter and animal waste, such as the wastes of slaughterhouse, fish market, urine and dung

of cattle, pigs, sheep, chicken, ducks, geese, goat, etc.

➽3. Industrial waste: wine lees, vinegar residue, manioc waste, sugar scum, furfural residue, etc.

➽4. Home scrap: food waste, the roots and leaves of vegetables, etc.

➽5. Sludge: the sludge of the river, sewer, etc.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Jinruifu

-

Voltage:

-

380v

-

Weight:

-

3500 KG

-

Dimension(L*W*H):

-

depending on model

-

Features:

-

Automatic remote control,Low odor

-

Name:

-

Compost Turner Making Machines High Productivity

-

Function:

-

Fertilizer Waste Fermentation

-

Color:

-

Green/Red/Blue or custom

-

Advantage:

-

Fully automatic remote control,Low odor, environmentally friendly

-

Application field:

-

Animal Manure Waste Compost Fermentation

-

Certificate:

-

CE ISO9001

-

Machine Type:

-

Fermentation Compost Turning Machine

-

Delivery time:

-

15 Days

Quick Details

-

Application:

-

Fermentation of organic waste

-

Production Capacity:

-

500-700m3/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jinruifu

-

Voltage:

-

380v

-

Weight:

-

3500 KG

-

Dimension(L*W*H):

-

depending on model

-

Features:

-

Automatic remote control,Low odor

-

Name:

-

Compost Turner Making Machines High Productivity

-

Function:

-

Fertilizer Waste Fermentation

-

Color:

-

Green/Red/Blue or custom

-

Advantage:

-

Fully automatic remote control,Low odor, environmentally friendly

-

Application field:

-

Animal Manure Waste Compost Fermentation

-

Certificate:

-

CE ISO9001

-

Machine Type:

-

Fermentation Compost Turning Machine

-

Delivery time:

-

15 Days

Kind reminder:

Dear customers, if you have purchased our equipment, we can provide fermentation strains and on-site guidance on fermentation process. Please feel free to contact us.

Product Description

Brief introduction:

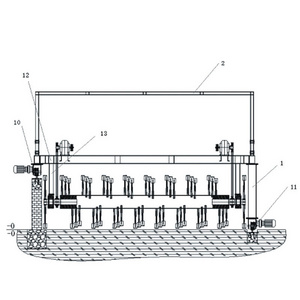

The crawler type compost turner belongs to the ground pile fermentation mode, which is the most economical mode of saving soil and human resources at present. The material needs to be piled up into a stack, then the material is stirred and crushed at regular intervals by the turning machine, and the decomposition of organic matter will be under aerobic conditions.

It also has a broken function, which greatly saves time and labor force, making the production efficiency and product quality of the organic fertilizer plant improved significantly, and the cost reduced greatly. When the turning machine works, the sludge, sticky chicken manure and other materials can be well stirred with the fungus and straw powder, creating a better aerobic environment for the fermentation

of materials. It not only ferments faster than deep groove type, but also effectively prevents the production of harmful and odorous gases such as hydrogen sulfide, amine gas and indole during fermentation, which is in line with environmental protection requirements.

of materials. It not only ferments faster than deep groove type, but also effectively prevents the production of harmful and odorous gases such as hydrogen sulfide, amine gas and indole during fermentation, which is in line with environmental protection requirements.

Technological advantages of remote compost

turner

:

Our factory have upgraded the ordinary

compost turner

to

remote compost turner,

Implement fully automated operations.

a. Short fermentation cycle and fast evaporation of water.

b. The flipping shaft and flipping teeth are made of high manganese material, resulting in higher wear resistance.

c. The flipping shaft has functions of crushing and stirring, with a long flipping distance and sufficient aerobic fermentation.

d. Hydraulic system, capable of achieving infinitely variable speed.

e. The machine is equipped with remote control operation, and the operator is no longer plagued by odors and high temperatures.

f. The machine is equipped with an emergency operating handle, which allows the operator to perform emergency operations on the machine.

g. The track chassis adopts engineering track machines, with a longer service life.

Raw Material:

|

Model

|

JRLD-2600

|

JRLD-3000

|

|

Diesel engine

|

huadong 4102

|

huadong 4108

|

|

Compost max width

|

2.6 m

|

3 m

|

|

Compost max height

|

1.2 m

|

1.3 m

|

|

Width of rubber track

|

2×0.3 m

|

2×0.3 m

|

|

Maximum diameter of raw material

|

250mm

|

250mm

|

|

Working flip distance

|

2-3 m

|

2-3 m

|

|

Maximum processing capacity

|

500-600m³/h

|

800-1000m³/h

|

|

Mode of operation

|

Remote control

|

Remote control

|

|

Roller diameter

|

700mm

|

700mm

|

|

Packing size

|

3*2*2.4

|

3.3*2.2*2.5

|

|

Working size

|

3*2.6*2.7

|

3.3*2.6*2.8

|

|

Weight

|

3100kg

|

3600kg

|

product details

Comparison of the same product

Application scenario

Hot Searches