- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Garment

-

Place of Origin:

-

Shandong, China

-

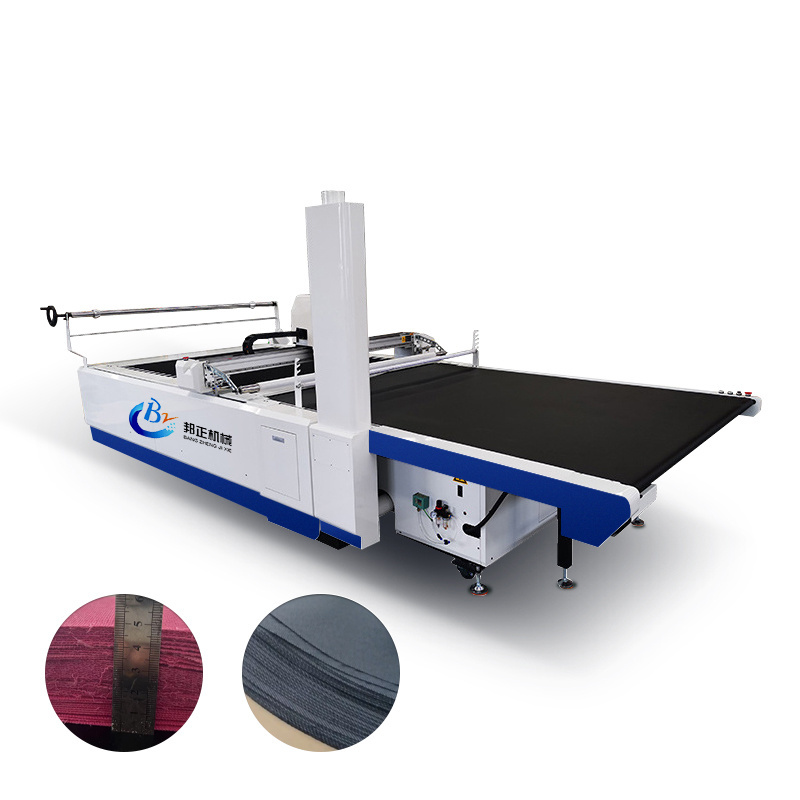

Brand Name:

-

Bangzheng Machinery

-

Dimension(L*W*H):

-

360cm*230cm*160cm

-

Weight:

-

4500 KG

-

Features:

-

Automatic Feeding System

-

X axis servo motor:

-

For Japanese Panasonic servo drive motor

-

Y axis servo motor:

-

For Japanese Panasonic servo drive motor

-

T axis servo motor:

-

For Japanese Panasonic servo drive motor

-

Z axis servo motor (vibration axis):

-

For Japanese Panasonic servo drive motor

-

Control System:

-

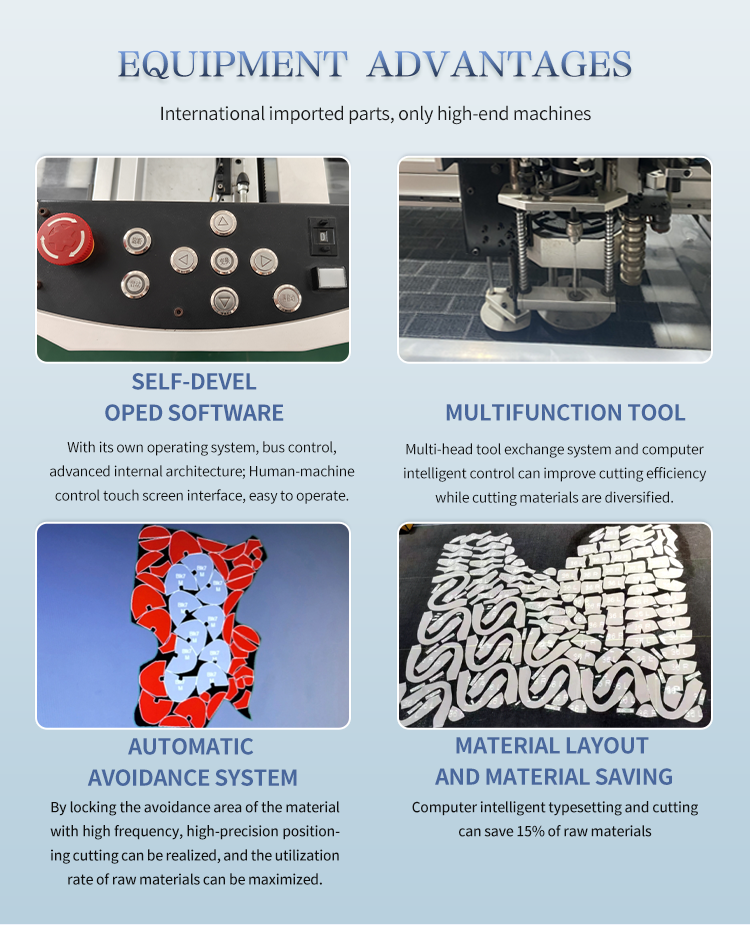

Independent research and development

-

sensor:

-

Import Omron

-

guide:

-

Taiwan PMI

-

drag chain cable:

-

German igus

-

Vacuum adsorption turbo pump:

-

Golden Bridge

-

Head hydraulic buffer:

-

For Japan imported SMC

Quick Details

-

Production Capacity:

-

5000 Sets/year

-

Voltage:

-

220-380V

-

Marketing Type:

-

New Product 2023

-

Application:

-

Garment

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Bangzheng Machinery

-

Dimension(L*W*H):

-

360cm*230cm*160cm

-

Weight:

-

4500 KG

-

Features:

-

Automatic Feeding System

-

X axis servo motor:

-

For Japanese Panasonic servo drive motor

-

Y axis servo motor:

-

For Japanese Panasonic servo drive motor

-

T axis servo motor:

-

For Japanese Panasonic servo drive motor

-

Z axis servo motor (vibration axis):

-

For Japanese Panasonic servo drive motor

-

Control System:

-

Independent research and development

-

sensor:

-

Import Omron

-

guide:

-

Taiwan PMI

-

drag chain cable:

-

German igus

-

Vacuum adsorption turbo pump:

-

Golden Bridge

-

Head hydraulic buffer:

-

For Japan imported SMC

Product Description

|

clipping height

|

|

|

1-11 cm

|

|

|||

|

Effective cropping width

|

|

|

1700mm

|

|

|||

|

Effective cutting length

|

|

|

Automatic feeding unlimited length

|

|

|||

|

Automatic feeding unlimited length

|

|

|

Automatic feeding unlimited length

|

|

|||

|

Way of transporting the knife

|

|

|

Way of transporting the knife

|

|

|||

|

cutting speed

|

|

|

0-60m/min

|

|

|||

|

Cutting knife grinding

|

|

|

Double wheel counter-rotating grinding

|

|

|||

|

Adsorption method

|

|

|

Frequency conversion vacuum constant pressure control mode

|

|

|||

|

safety devices

|

|

|

automatic induction

|

|

|||

|

using electric

|

|

|

Three-phase AC380V/50Hz/25Kw

|

|

|||

|

operation panel

|

|

|

touch control panel

|

|

|||

|

clipping parameters

|

|

|

Input LAN, USB

|

|

|||

|

Device weight

|

|

|

About 4500Kg

|

|

|||

|

Other functions

|

|

|

Mobile cutting device, automatic feeding device, pattern scanning, adsorption bed

|

|

|||

|

operating system

|

|

|

Supports the overall rotation of the nesting chart, knife-edge conversion, single-piece recutting, one-key deletion of overlapping

areas (supports removal of repeated lines), automatic multi-layer cutting bed for residual cloth cutting, automatic cloth spreading machine, and air floatation table |

|

|||

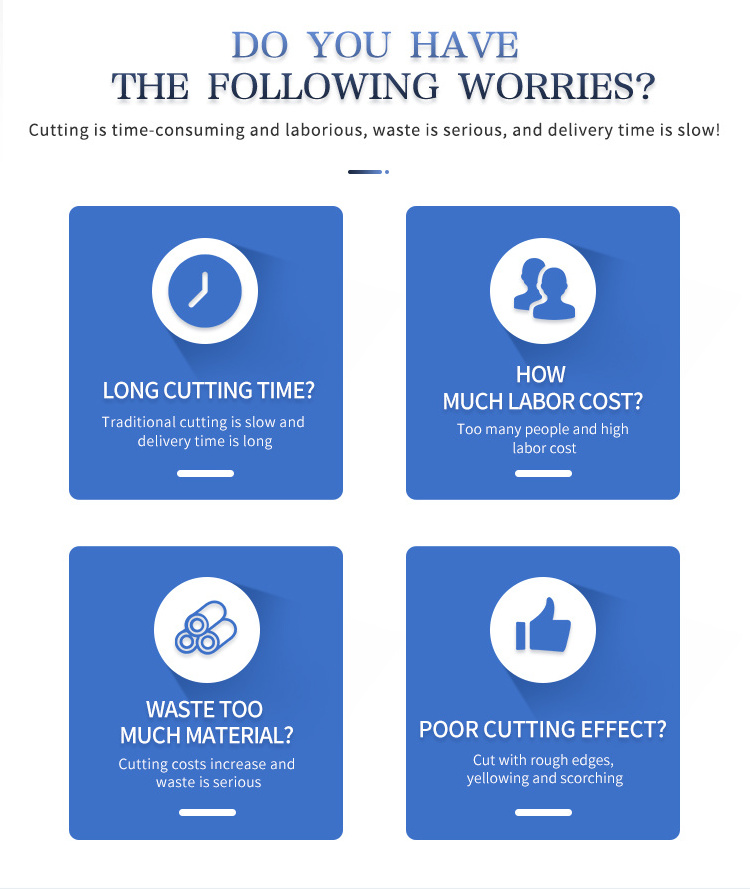

1. The nesting system adopts computer design, which effectively combines manual and computer automation to improve the nesting efficiency;

2. It can realize zero-distance cutting and effectively save raw materials;

3. Computer-controlled automatic cutting, replacing a large number of workers, to achieve mass production;

4. The pieces cut by the equipment have high cutting precision and can be directly sewn, effectively improving the sewing efficiency of lathe workers;

5. The cutting machine control software supports multi-source data formats: it can directly receive common clothing design and typesetting software, etc.;

6. The unique algorithm and motion control technology realize the seamless connection of straight lines and arcs with high cutting precision;

7. The device adopts automatic sharpening technology. The sharpening time can be designed according to the characteristics of the fabric to effectively prolong the service life of the tool;

8. No need to print and save paper plates, high reuse rate, easy to manage plate making;

9. The replacement of consumables is simple and the replacement cost is low;

10. High degree of automation and simple operation.

Product advantages

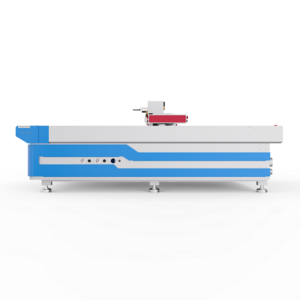

Product parameters

|

Product model:

GSD-1825

|

|

|

|

|

||||

|

Cutting height:

1-11cm (after adsorption)

|

|

|

|

|

||||

|

Effective cutting width:

1800mm(Size can be customized)

|

|

|

|

|

||||

|

Effective cutting length:

2500mm(Size can be customized)

|

|

|

|

|

||||

|

Tool transport method:

reciprocating tool transport

|

|

|

|

|

||||

|

Operating speed:

0-1000mm

|

|

|

|

|

||||

|

Cutter grinding:

double-wheel counter-rotating grinding (automatic grinding)

|

|

|

|

|

||||

|

Adsorption mode:

variable frequency vacuum constant pressure control mode

|

|

|

|

|

||||

|

Safety device:

automatic sensing

|

|

|

|

|

||||

|

Power supply:

three-phase AC380V/50Hz 25Kw

|

|

|

|

|

||||

|

Operating computer:

ordinary computer, Windows7

|

|

|

|

|

||||

|

Operation panel:

touch control panel

|

|

|

|

|

||||

|

Cropping parameters:

input LAN, USB

|

|

|

|

|

||||

|

Unit weight:

about 3000Xg

|

|

|

|

|

||||

|

Standard assembly function:

1. Automatic adjustment of cutting speed

2. Cutting vacuum secondary compensation (follow-up filmcovering air supply)

3. Inductive safety protection device

4. Automatic sharpening device

|

|

|

|

|

||||

|

Operating system:

support the overall rotation of the layout diagram, knife edge conversion, single piece re-cutting, one-key deletion of overlapping areas (support the removal of duplicate lines), and residual cutting

|

|

|

|

|

||||

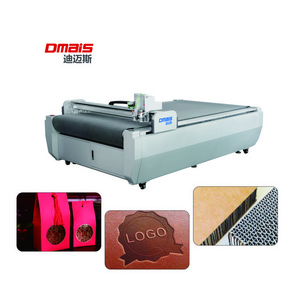

product display

Scenario shows

Customer Photos

Enterprise honor

Hot Searches