- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

10 KG

-

Product name:

-

woodworking tools

-

Material:

-

Alloy tool steel D2 1.2379 HSS SKD11 A8 9CrSi

-

Application:

-

Wood working industrial

-

Advantage:

-

High Performance

-

Package:

-

Wood Box

-

MOQ:

-

5pcs

-

Hardness:

-

58 - 63 HRC

-

Certificate:

-

CE

-

Shipping Method:

-

Air/Sea Shipping, or Courier

-

OEM Service:

-

Support

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Marketing Type:

-

Hot Product 2024

-

Brand Name:

-

HX

-

Weight (KG):

-

10 KG

-

Product name:

-

woodworking tools

-

Material:

-

Alloy tool steel D2 1.2379 HSS SKD11 A8 9CrSi

-

Application:

-

Wood working industrial

-

Advantage:

-

High Performance

-

Package:

-

Wood Box

-

MOQ:

-

5pcs

-

Hardness:

-

58 - 63 HRC

-

Certificate:

-

CE

-

Shipping Method:

-

Air/Sea Shipping, or Courier

-

OEM Service:

-

Support

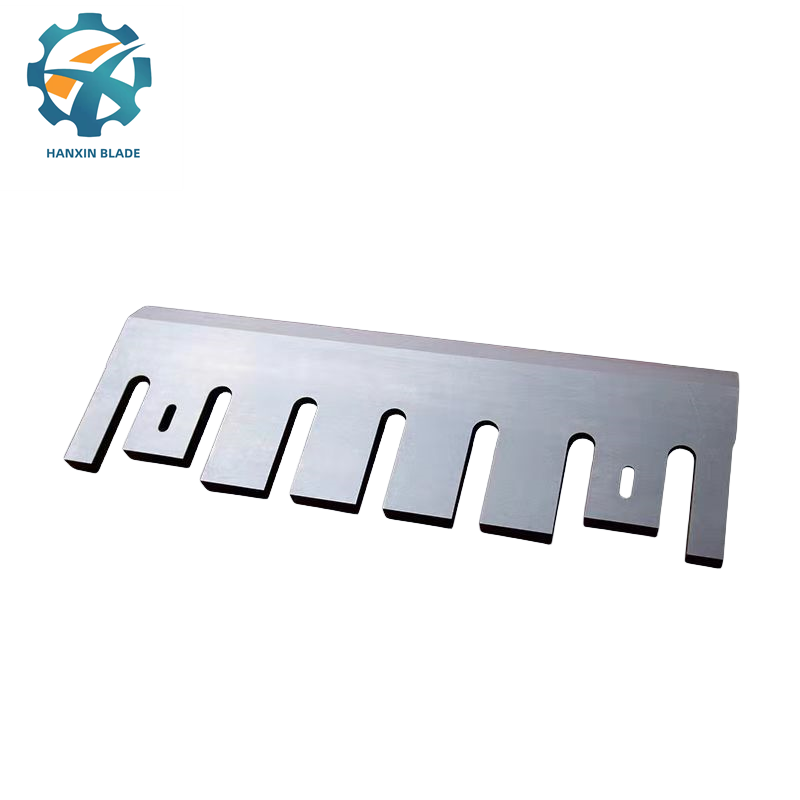

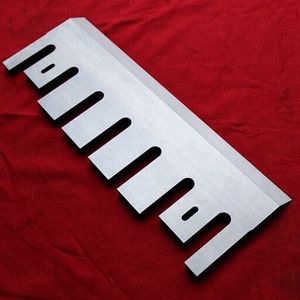

Woodworking Chipper Knives

Hanxin Knives and Blades has great manufacturing experience in producing Chipper Knives to meet the needs of various wood industries. With our highly experienced team and high-tech machines, we manufacture durable chipper knives manufactured to your application.

Our chipper knives for waste wood processing are manufactured from premium and high-quality alloy tool steels giving them the most cuts per blade which will in return increase your productivity and profitability, and minimize downtime.

Our chipper knives for waste wood processing are manufactured from premium and high-quality alloy tool steels giving them the most cuts per blade which will in return increase your productivity and profitability, and minimize downtime.

Is your wood chipper in need of new blades?

If your wood chipper needs new blades, get in touch with us to learn more about how our top-quality knives can enhance your operations .

If your wood chipper needs new blades, get in touch with us to learn more about how our top-quality knives can enhance your operations .

Chipper knives application

We manufacture cutting tools for the specific further processing of wood remnants according to the complete substantial usability of wood as wood chipping, crushing of waste timber, cutting timber to chips.

Our specialized chipper and counter knives enable you to produce high-quality wood chips for different purposes.

Some of the industries in which they are used:

• Pulp and paper

• Timber

• Plywood

If you are not sure if chipper knives are a good fit for your specific application feel free to consult with our engineers that

will help you choose the right knife for your specific application.

Our specialized chipper and counter knives enable you to produce high-quality wood chips for different purposes.

Some of the industries in which they are used:

• Pulp and paper

• Timber

• Plywood

If you are not sure if chipper knives are a good fit for your specific application feel free to consult with our engineers that

will help you choose the right knife for your specific application.

Are your current wood chipper blades failing to deliver the cutting performance you need?

Perhaps it’s time for a Hanxin upgrade. Our blades are not just replacements; they’re enhancements designed to increase the efficiency and longevity of your wood chipper.

Investing in Hanxin’s Wood Chipper Blades ensures that your chipper operates at its peak, reducing downtime and enhancing productivity. From the precise cutting edges to the exceptional resistance to wear, our blades are a testament to quality and commitment to your operational success.

We provide different material for choose

|

Material

|

Ordinary steel plate

|

Forged steel plate

|

Imported special steel plates

|

H13

|

H12

|

A8b

|

|||||

|

Hardness

|

48-52

|

55-56

|

56-58

|

58-60

|

58-60

|

60-62

|

|||||

|

Application

|

Poplar, pine, eucalyptus, elm, fruit wood, bamboo, straw, straw, etc

|

|

|

|

|

|

|||||

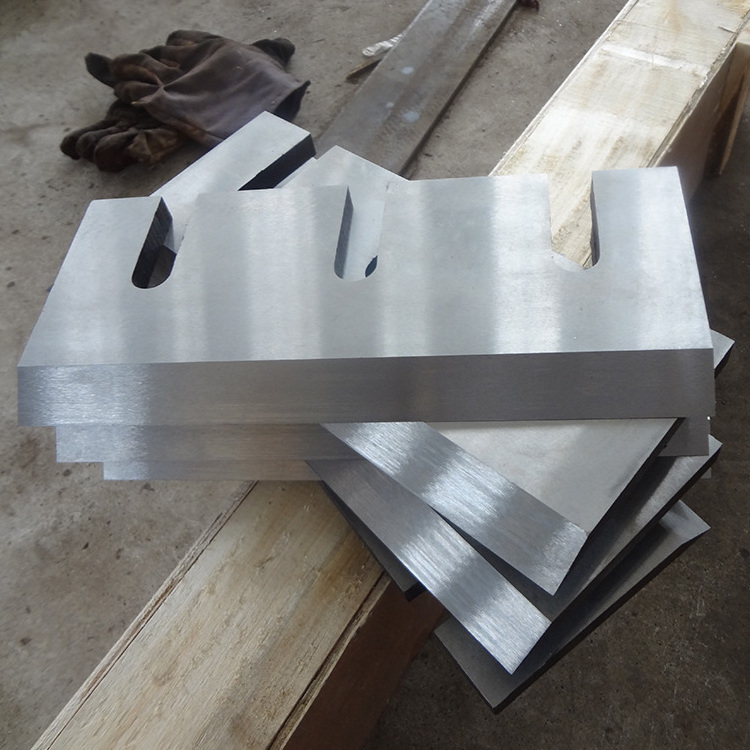

Heat temperature repeated forging at 3000°C

After thousands of rounds of hammering and forming, the forged blade material has high hardness, toughness, wear resistance, good texture, and corrosion resistance, ensuring that the blade has good wear resistance and a long service life.

OEM & ODM SERVICE AVAILABLE

Expand the potential of your operation with Hanxin’s OEM & ODM services. Whether you can provide us with your wood chipper’s model information or send us the specific blueprints, we can adapt our services to fit your needs precisely. Benefit from blades tailored to your unique requirements, as we diligently work to turn your specifications into high-performing reality. Opt for Hanxin’s personalized approach and experience the transformation in your operations!

Recommend Products

FAQ

sales manager

Contact Candice to get our most

up to date list.

Contact Candice on E:manager822650@njhanxin.com

M:+8613696733357

up to date list.

Contact Candice on E:manager822650@njhanxin.com

M:+8613696733357

1. Are you manufacturer of trading company?

We are a factory with 20 years of experience in blade production.

2. What data do I need to provide for you to produce blades?

The first choice is to provide drawings, which is the most accurate. Of course, if there are no drawings, you can measure the length, width, and thickness of your existing blades.

3. How do I pay to you?

(1) 30% deposit of the total amount to be paid by T / T in advance, the balance of 70%will be paid before the goods leave the factory.

(2) Alibaba platform credit insurance payment

4. How long is the lead time?

For standard size, that would be 2-3 working days;

We are a factory with 20 years of experience in blade production.

2. What data do I need to provide for you to produce blades?

The first choice is to provide drawings, which is the most accurate. Of course, if there are no drawings, you can measure the length, width, and thickness of your existing blades.

3. How do I pay to you?

(1) 30% deposit of the total amount to be paid by T / T in advance, the balance of 70%will be paid before the goods leave the factory.

(2) Alibaba platform credit insurance payment

(3)We can negotiate specific payment terms with our client.

4. How long is the lead time?

For standard size, that would be 2-3 working days;

For non-standard sizes and need to be customized , it would be about 15-25 working days.

Hot Searches