- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

L7

-

Feature:

-

No spark, wear resistant, replace easily and fast

-

Tip material:

-

Carbide

-

Manufacturing process:

-

Vacuum brazing and quenching process

-

Knife body material:

-

42CRMO alloy steel

-

characteristic:

-

Strong wear resistance

-

Installation requirements:

-

20mm or 22mm

Quick Details

-

Weight (KG):

-

1.5

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

YKDRILL, Yikuang

-

Model Number:

-

L7

-

Feature:

-

No spark, wear resistant, replace easily and fast

-

Tip material:

-

Carbide

-

Manufacturing process:

-

Vacuum brazing and quenching process

-

Knife body material:

-

42CRMO alloy steel

-

characteristic:

-

Strong wear resistance

-

Installation requirements:

-

20mm or 22mm

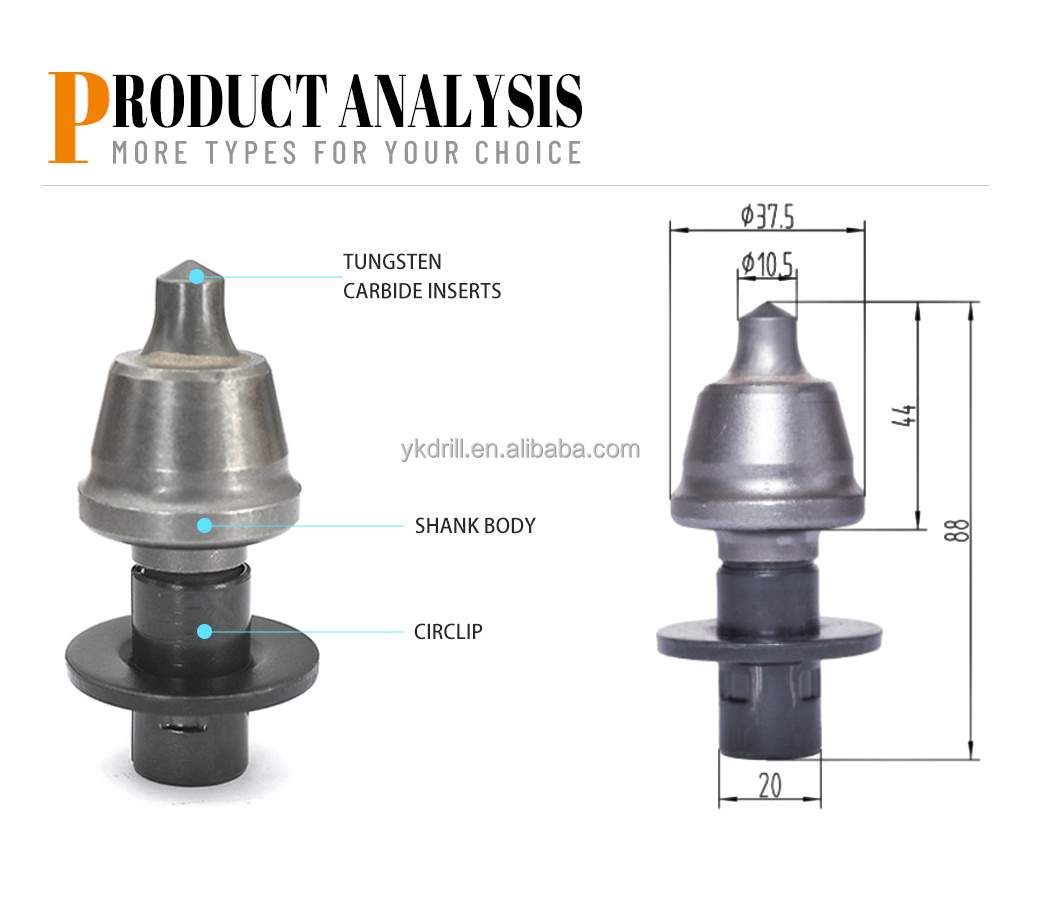

Asphalt pavement milling teeth

asphalt/concrete road milling cutter removal tool teeth

Scope of application of milling teeth: widely used in pavement surface maintenance construction on high-grade highways, municipal roads, airports, squares and other places. Its main construction object is asphalt mixture pavement. By changing the cutter head material, it can also mill and roughen cement concrete pavement. It can be used for road renovation, road repaving, and road repair; it can also be used for milling and roughening of roads, squares, and bridges; and it can also be used for trench milling and grooving operations.

1. Asphalt milling gear alloy is fired with coarse-grained cobalt powder at low pressure, which can increase the wear resistance of the alloy and extend its service life. Hard solder and special welding processing technology can make the connection point between the tool handle and the alloy stronger.

2. The snap ring of the asphalt milling teeth made of elastic steel can withstand long-term expansion force.

3. The asphalt milling teeth are made of hard elastic steel plates and the washers can reduce wear on the tool holder.

4. The asphalt milling tooth cutter holder is made of 42CrMo raw material and is manufactured using a hot precision forging process, so that its shape reaches the minimum resistance during use and ensures smooth cutting and milling of the cutter head;

5. All key parts of the asphalt milling tooth cutter holder are processed by CNC machine tools to ensure the accuracy of their dimensions;

6. The asphalt milling tooth cutter holder is heat treated as a whole to increase wear resistance and extend service life.

Factory real landscape

Certifications

DRILL PIPE AND BIT DELIVERY SCENE

DRILL BIT PRODUCT DISPLAY

Recommend Products

Exhibition

CUSTOMERS COME TO VISIT

FAQ

Congratulations, you have found the source manufacturer. YK Drilling Tools produces water well drilling rigs, drill pipes and matching drill bits. Various types of drilling tools can be customized.

Contact us immediately to understand your drilling needs.

FAQ

The information you may like to know before order:

1. Are you a manufacture or a trade company?

We are a professional manufacturer.

2. Handling time for an order

Based on order quantity, normally it takes 25 days for production.

Only 2 or 3 days if we have stock on your request size.

3. Quality Control

We have our own experienced QC.

There will be strict inspection and testing for every order before shipping out.

4. After Services:

1. Our sales team will response for your question within 24 hours (Holidays Excluded).

2. Technical Support will be available in any time.

3. Free replacement will provide once the failure confirmed caused by our product quality.

5. Methods of Payment:

T/T (Telegraphic Transfer) or Western Union or L/C at sight.

6. Do you have quality control system?

Yes, we check every production process and test pressure for each tool to make sure no problem.

7. How can I get a brochure and buy your products?

Very easy! Please leave me a message and tell me your requirements, let me know you are interested in our products. Will talk to you about the details shortly.

8. Can you tell me your size and specification?

1.Give me your drawing with detail requirements.

2. Give me the product no.after you checked our booklet.

3. Don't forget to tell me the quantities, this is very important.

4. Give me your size and specifications.

5. Your destination port.

Save worry and effort, enjoy low price!!

This price is a reference price, and the final price is subject to the official negotiation result

of the buyer and the seller!

SHIPPING METHODS

Hot Searches