Melting and mixing the plastic , extruding the material with filter.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

15500*1600*2600

-

Power (kW):

-

customized

-

Weight:

-

6000

-

Screw Speed (rpm):

-

10 - 75 rpm

-

Model:

-

LDD-SJP-140-130

-

Screw dia.(mm):

-

140 130

-

Long dia.ratio:

-

28:1 10:1

-

Output((kg/h):

-

350-400

-

Power(kw):

-

75/18.5

-

Rotate speed(r/min):

-

10-75

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Application:

-

Waste Plastic Recycling

-

Keywords:

-

Recycling Plastic Pelletizing Machine

-

Raw material:

-

PP PE Film Bags Material

Quick Details

-

Output (kg/h):

-

350 - 400 kg/h

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Lvhua

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

15500*1600*2600

-

Power (kW):

-

customized

-

Weight:

-

6000

-

Screw Speed (rpm):

-

10 - 75 rpm

-

Model:

-

LDD-SJP-140-130

-

Screw dia.(mm):

-

140 130

-

Long dia.ratio:

-

28:1 10:1

-

Output((kg/h):

-

350-400

-

Power(kw):

-

75/18.5

-

Rotate speed(r/min):

-

10-75

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Application:

-

Waste Plastic Recycling

-

Keywords:

-

Recycling Plastic Pelletizing Machine

-

Raw material:

-

PP PE Film Bags Material

Product Description

Features:

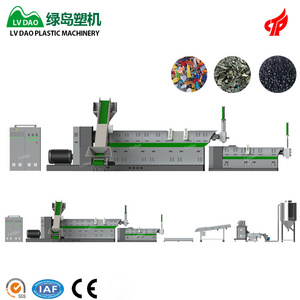

LDD series is used for PP PE ABS PA PS PET crushed material extruding and granule-making. It adopt the two-step structure to meet

the the double-layer filter purpose. It can effectively remove the impurities from the recycling material and fully exhaust the

gas.It can produce ample,consolidated and fine luster granules.

the the double-layer filter purpose. It can effectively remove the impurities from the recycling material and fully exhaust the

gas.It can produce ample,consolidated and fine luster granules.

Use:

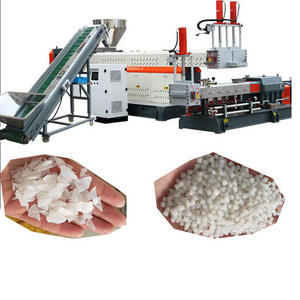

This machine can process a variety of thermoplastic plastics,such as PC,PA,PP,ABS,PE,POM,PET etc. Different from LDC series, thiskind of machine has two even three stages.

Material:

PP PE ABS PA PS PPR POM PET

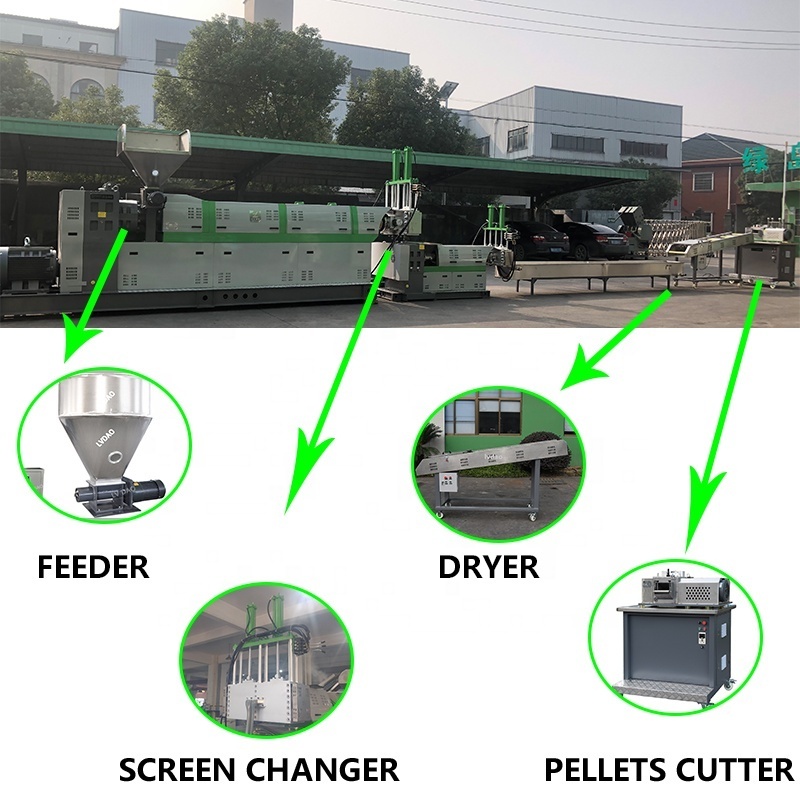

Machine Parts:

Melting and mixing the plastic , extruding the material with filter.

Filtering the impurity from the plastic

Melting and mixing the plastic again , double filtering of the plastic

Melting and mixing the plastic again , double filtering of the plastic

Make the pellet

conveying the pellet into packing storage silo

Working Flow:

Feeding system→ Main extruder →Main machine screen changer→Baby extruder →Baby machine screen changer→Water cooling tank→Air blow→ Plastic pelletizing→ Packing silo with conveying blower

The machine parameters:

|

Model

|

Screw dia.(mm)

|

Long dia. ratio

|

Output(kg/h)

|

Power(kw)

|

Rotate speed(r/min)

|

|

LDD-SJP-80-70

|

Ø80,Ø70

|

28:1,10:1

|

50-100

|

18.5/7.5

|

10-75

|

|

LDD-SJP-90-85

|

Ø90,Ø85

|

28:1,10:1

|

100-150

|

22/7.5

|

10-75

|

|

LDD-SJP-100-95

|

Ø100,Ø95

|

28:1,10:1

|

150-200

|

30/11

|

10-75

|

|

LDD-SJP-110-105

|

Ø110,Ø105

|

28:1,10:1

|

200-250

|

37/11

|

10-75

|

|

LDD-SJP-120-110

|

Ø120,Ø110

|

28:1,10:1

|

250-300

|

45/15

|

10-75

|

|

LDD-SJP-130-120

|

Ø130,Ø120

|

28:1,10:1

|

300-350

|

55/15

|

10-75

|

|

LDD-SJP-140-130

|

Ø140,Ø130

|

28:1,10:1

|

350-400

|

75/18.5

|

10-75

|

|

LDD-SJP-150-140

|

Ø150,Ø140

|

28:1,10:1

|

400-450

|

90/22

|

10-75

|

|

LDD-SJP-160-150

|

Ø160,Ø140

|

28:1,10:1

|

450-500

|

110/30

|

10-75

|

|

LDD-SJP-180-160

|

Ø180,Ø160

|

28:1,10:1

|

500-600

|

132/37

|

10-75

|

other machine :

Flim Force Feeder Recycling Machine Line

Water Ring Hot Cutting Recycling Machine line

Plastic Shredder

Plastic Cutter

Plastic Crusher

Hot Searches