- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

YEAMING

-

Condition:

-

New

-

Weight:

-

172

-

Max Jaw Opening:

-

Customized

-

Roller material:

-

40Mn2

-

O-Ring:

-

Rubber

-

Side Cover:

-

QT450-10

-

Double Metal Set:

-

CuPb10Sn10

-

Shaft:

-

45#

-

Inside Hex Bolt:

-

JB/T1000-1977

-

Floating Seal:

-

15CrNiMo3

-

Lubricated oil:

-

SAE85

-

Roller hardness:

-

HRC54-59,depth 2-3mm

-

Shaft hardness:

-

HRC51°-56°H

Quick Details

-

Suitable Excavator(ton):

-

1.2ton, 5 ton

-

Bucket capacity:

-

4m³

-

Bucket type:

-

Other

-

Place of Origin:

-

China

-

Brand Name:

-

YEAMING

-

Condition:

-

New

-

Weight:

-

172

-

Max Jaw Opening:

-

Customized

-

Roller material:

-

40Mn2

-

O-Ring:

-

Rubber

-

Side Cover:

-

QT450-10

-

Double Metal Set:

-

CuPb10Sn10

-

Shaft:

-

45#

-

Inside Hex Bolt:

-

JB/T1000-1977

-

Floating Seal:

-

15CrNiMo3

-

Lubricated oil:

-

SAE85

-

Roller hardness:

-

HRC54-59,depth 2-3mm

-

Shaft hardness:

-

HRC51°-56°H

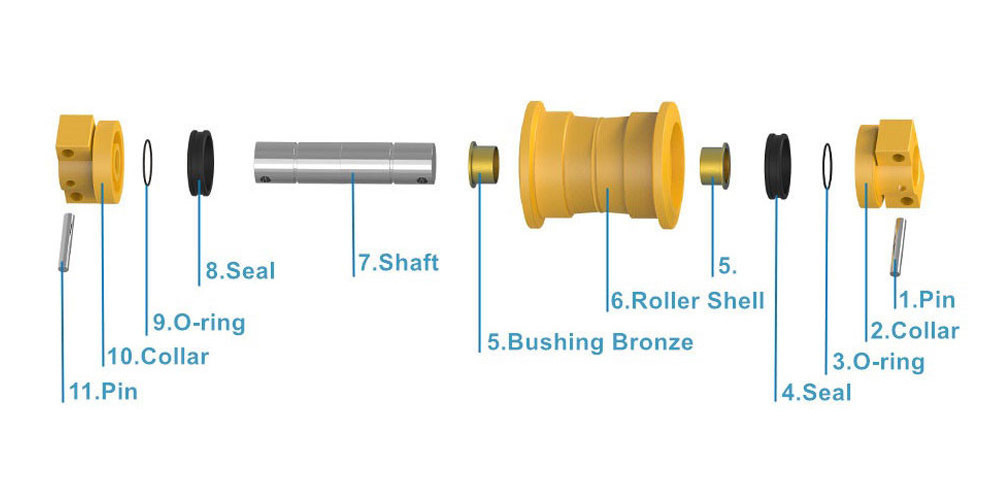

Products Description >>>

The materials avaliable for Track roller and Carrier roller are 40Mn2、40MnB、50Mn,depending on working conditions.The rollers are normalized with precision forging before overall heat treatment to achieve surface hardness or HRC52-6 and the depth of hardened layer reaches more than 7-10mm(HRC45).This ensures higher durability with high impact resistance and surface wear resistance on the contact surface of the roller.High quality floating saels and lubrcating system are usde to adapt to different climate and temperature The track and carrier rollers is able to work under severe working conditions or climate ranging from -45℃~120℃,keeping the components free from miantenance.

Our Track Roller is welded before precision machining in vertical CNC turning lathe and hence,there is no concentricity errors.The process gives unparalleled quality quality advantage over that of precision machning before welding.Therefore,the operation of roller is be guaranteed against occurrence of rapid wearing problems,which significantly improves service life of the products.

|

Roller material

|

40Mn2

|

O-Ring

|

Rubber

|

|

Side Cover

|

QT450-10

|

Double Metal Set

|

CuPb10Sn10

|

|

Shaft

|

45#

|

Inside Hex Bolt

|

JB/T1000-1977

|

|

Floating Seal

|

15CrNiMo3

|

Lubricated oil

|

SAE85

|

|

Roller hardness

|

HRC54-59,depth 2-3mm

|

Shaft hardness

|

HRC51°-56°H

|

Application >>>

|

Parts name

|

Excavator Model

|

Parts name

|

Excavator Model

|

|

Track roller

|

SK30

|

Double flange track roller

|

SH55

|

|

Track roller

|

SK30

|

Double flange track roller

|

SH60

|

|

Big size track roller

|

SK45

|

Single flange track roller

|

SH60

|

|

Track roller

|

SK50-1

|

Double flange track roller

|

E301

|

|

Track roller

|

SK50-6

|

Track roller

|

E303

|

|

Track roller

|

SK60-3

|

Track roller

|

E303

|

|

Track roller

|

SK60-5

|

Track roller

|

E305

|

|

Track roller

|

SK100

|

Track roller

|

E305

|

|

Track roller

|

SDLG60

|

Double flange track roller

|

E70B

|

|

Track roller

|

Sunward80

|

Single flange track roller

|

E70B

|

|

Track roller

|

SY65

|

Track roller

|

E120B

|

|

Track roller

|

Sunward80

|

Track roller

|

Kubota 161

|

|

Track roller

|

CHTC95

|

Track roller

|

Kubota 163

|

|

Track roller

|

E315D

|

Track roller

|

Liugong906

|

|

Track roller

|

SK60-8

|

Track roller

|

Liugong908

|

|

Track roller

|

DH35

|

Track roller

|

CASE55

|

|

Track roller

|

DH55

|

Track roller

|

Vio60

|

|

Track roller

|

DX60

|

Track roller

|

E320

|

|

Track roller

|

YC13

|

Track roller

|

R60-5

|

|

Track roller

|

YC18

|

Track roller

|

R60-7

|

|

Track roller

|

YC35

|

Track roller

|

VIO15

|

|

Track roller

|

YC60

|

Track roller

|

VIO20

|

|

Track roller

|

YC85

|

Track roller

|

VIO35

|

|

Track roller

|

Sunwar50

|

Track roller

|

VIO40

|

|

Track roller

|

Sunwar70

|

Track roller

|

VIO55

|

|

Track roller

|

Vio20

|

Track roller

|

HD250

|

|

Track roller

|

Vio35

|

Track roller

|

HD450

|

|

Track roller

|

Vio60

|

Track roller

|

HD700

|

|

Track roller

|

Vio25

|

Double flange track roller

|

EX30

|

|

Track roller

|

Vio40

|

Double flange track roller

|

EX55

|

|

Single flange track roller

|

IHI35

|

Double flange track roller

|

EX60

|

|

Double flange track roller

|

IHI35

|

Single flange track roller

|

EX60

|

|

Single flange track roller

|

IHI60

|

Track roller

|

EX70

|

|

Double flange track roller

|

IHI60

|

Track roller

|

EX100

|

|

Track roller

|

H45

|

Track roller

|

PC15

|

|

Track roller

|

KX101

|

Track roller

|

PC18

|

|

Track roller

|

Doosan331

|

Track roller

|

PC20-3

|

|

Track roller

|

Doosan322

|

Single flange track roller

|

PC30

|

|

Track roller

|

Doosan337

|

Double flange track roller

|

PC30

|

|

Track roller

|

E307

|

Big size track roller

|

PC30

|

|

Track roller

|

DH130

|

Single flange track roller

|

PC40

|

|

Track roller

|

R80

|

Double flange track roller

|

PC40

|

|

Track roller

|

Foton65

|

Big size track roller

|

PC40

|

|

Track roller

|

Foton80

|

Track roller

|

PC60-5

|

About Us >>>

Xi’An Yingming Machine Co.,Ltd.

is a company specialized in manufacturing and sales of the engineering machinery. The company has complete supply ability for engineering machine products. With more than 20 years professional innovation and manufacturing experiences, we can offer clients various engineering machine parts especially for undercarriage parts and ground engaging parts of excavator like track roller, Carrier roller, track link assy, sprocket and bucket for different excavator machine brand like KOMATSU, CAT, HITACHI, KOBELCO, SUMITOMO, KATO, HYUNDAI, DAEWOO . With high quality products, Price advantage and quality customer service, Yingming Machine Co., Ltd. consistently wins high comment and good reputation from a lot of clients from domestic and oversea market in the industry.

Factory Facility >>>

Packing & Storage >>>

Quality Control >>>

Delivery >>>

FAQ >>>

1. You are a trader or a manufacture?

We are an industry and trade integration business.

2. How can I be sure the part will fit my excavator?

Give us correct model number/machine serial number/ any numbers on the parts itself. Or measure the parts give us dimension or drawing.

3. How about the payment terms?

We usually accept T/T or Trade Assurance. other terms also could be negotiated.

4. What is your minimum order?

It depends on what you are buying. Normally, our minimum order is one 20’ full container and LCL container (less than a container load) can be acceptable.

5. What is your delivery time?

FOB any Chinese port : 20 days . If there are any parts in stock , our delivery time is only 0-7 days.

6. What about Quality Control?

We have a perfect QC system for the perfect products. A team who will detect the product quality and specification piece carefully, monitoring every production process until packing is complete, to ensure product safety into container.

Hot Searches